Wind turbine installation comprising an apparatus for protection of anchor bolts and method of installation

a technology for wind turbines and anchor bolts, which is applied in mechanical devices, building repairs, foundation engineering, etc., can solve the problems of reducing ease and damaging surrounding grout, and achieve the effect of preventing or greatly limiting the axial migration of water or other electrolytes and preventing the adhesion of grou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Prior Art Bolt Protection Devices

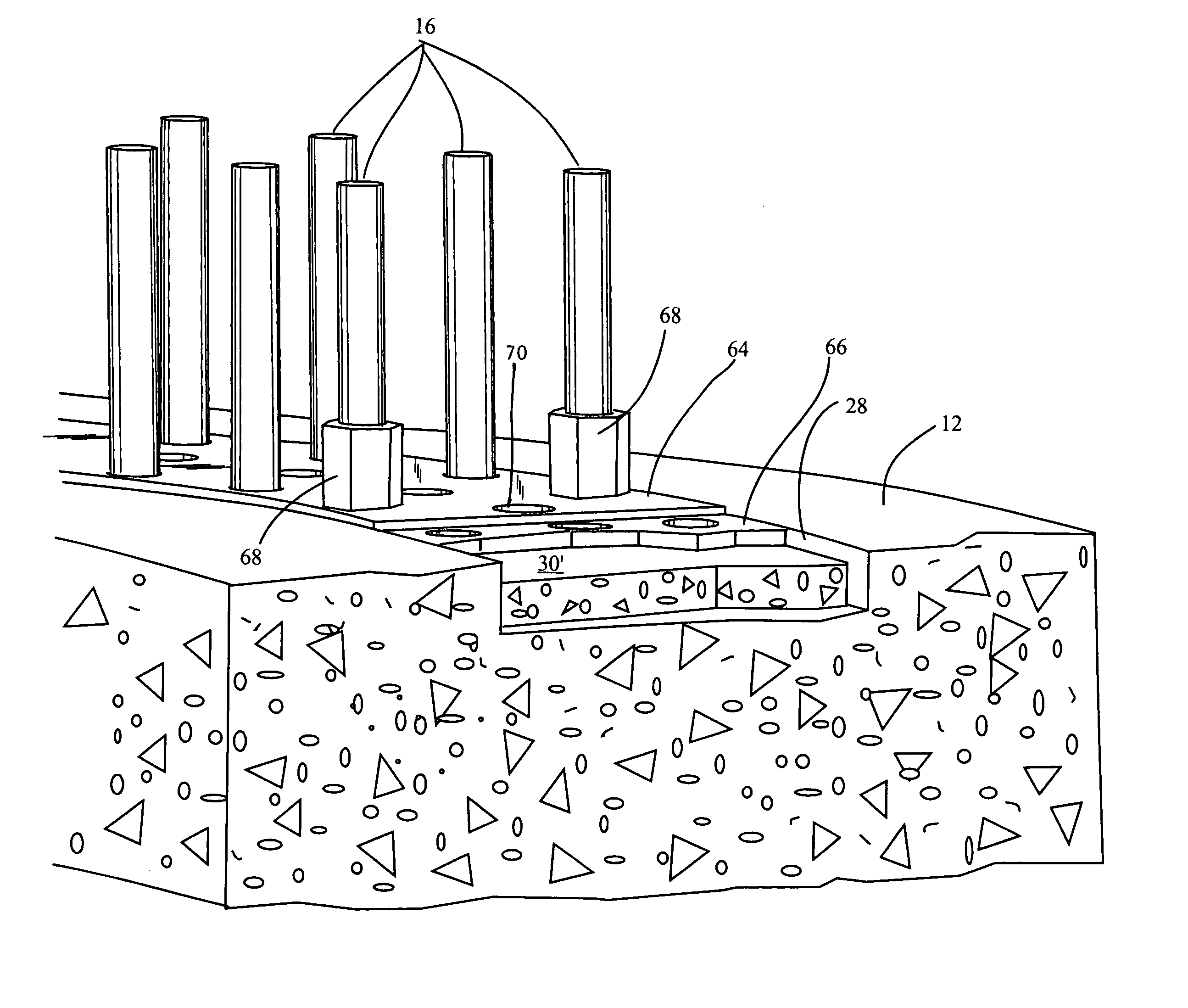

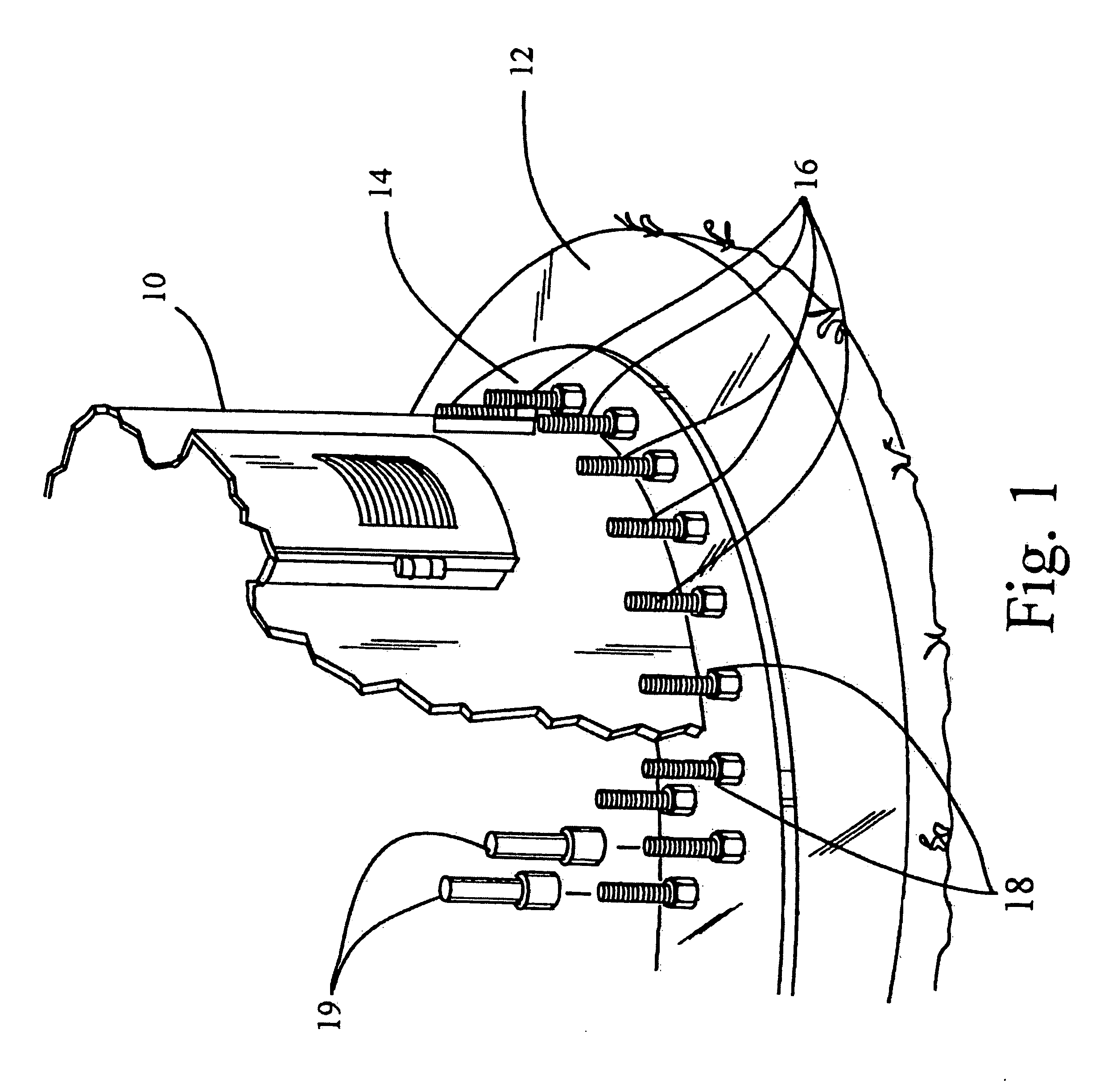

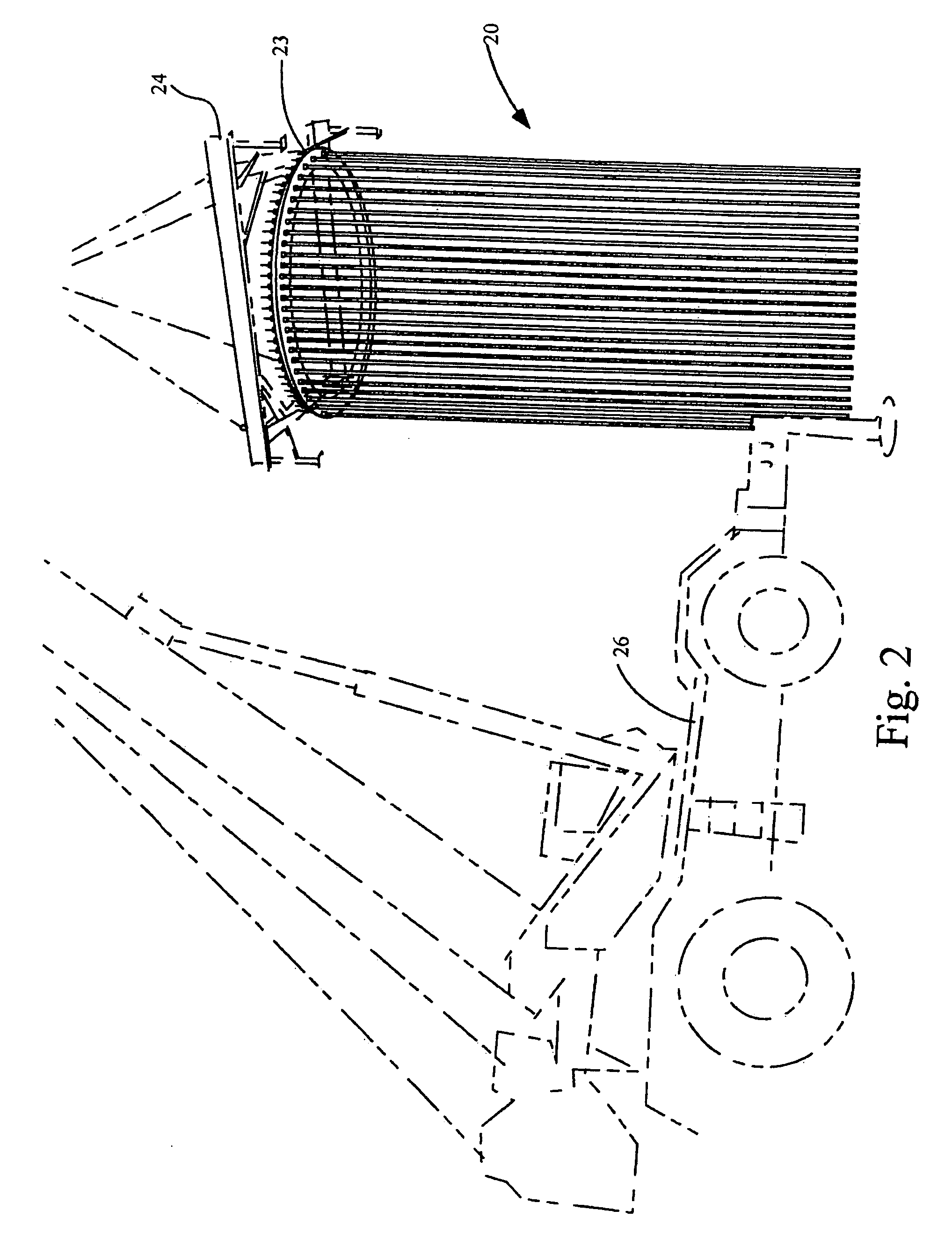

[0036]FIG. 1 generally depicts the base 10 of a wind turbine set upon a foundation 12. Base 10 comprises a flange 14, by which the base is attached to foundation 12 with anchor bolts 16. As shown in FIG. 1, the anchor bolts 16 may be placed in side-by-side pairs, the pairs extending radially from the center of the foundation 12 forming an inner ring of bolts and an outer ring of bolts. The bolt pattern is, of course, determined by the bolt pattern on the mounting flange 14. Each anchor bolt 16 has a corresponding nut 18 which is used to secure the base 10, and to apply tension to the bolt. The exposed portion of each bolt 16 is usually protected with a bolt cap 19.

[0037]A large number of anchor bolts 16 is typically used for this type of foundation. For example, Henderson discloses an embodiment having forty-eight tensioning bolts in the inner ring and forty-eight tensioning bolts in the outer ring for a total of ninety-six. In Henderson's foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com