Construction method for chamber type bridge maintaining external pre-stress

A technology of external prestressing and construction method, applied in bridge maintenance, bridge, bridge reinforcement and other directions, can solve the problem of not being able to use newly poured concrete for anchoring, etc., and achieve the effect of simple construction and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

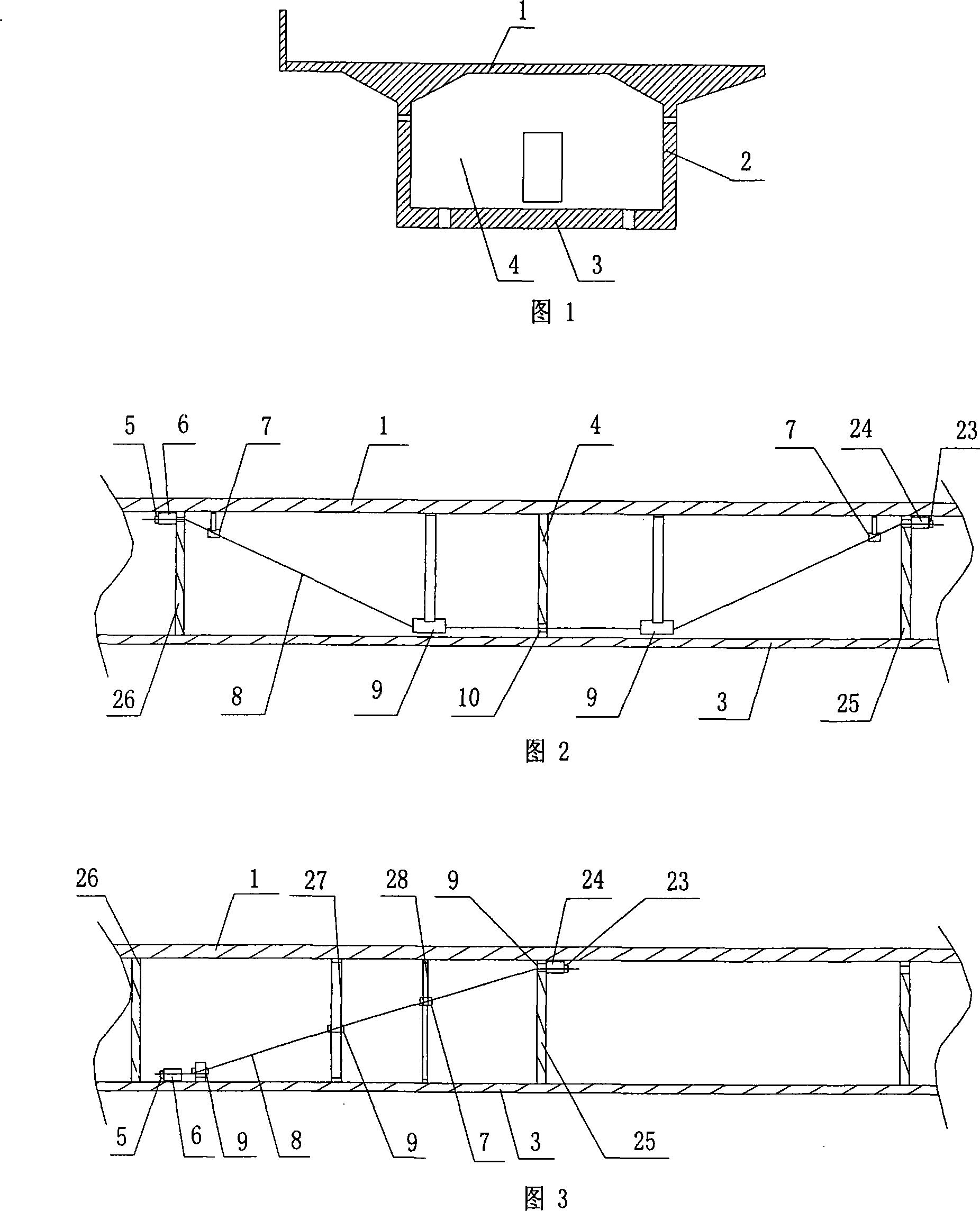

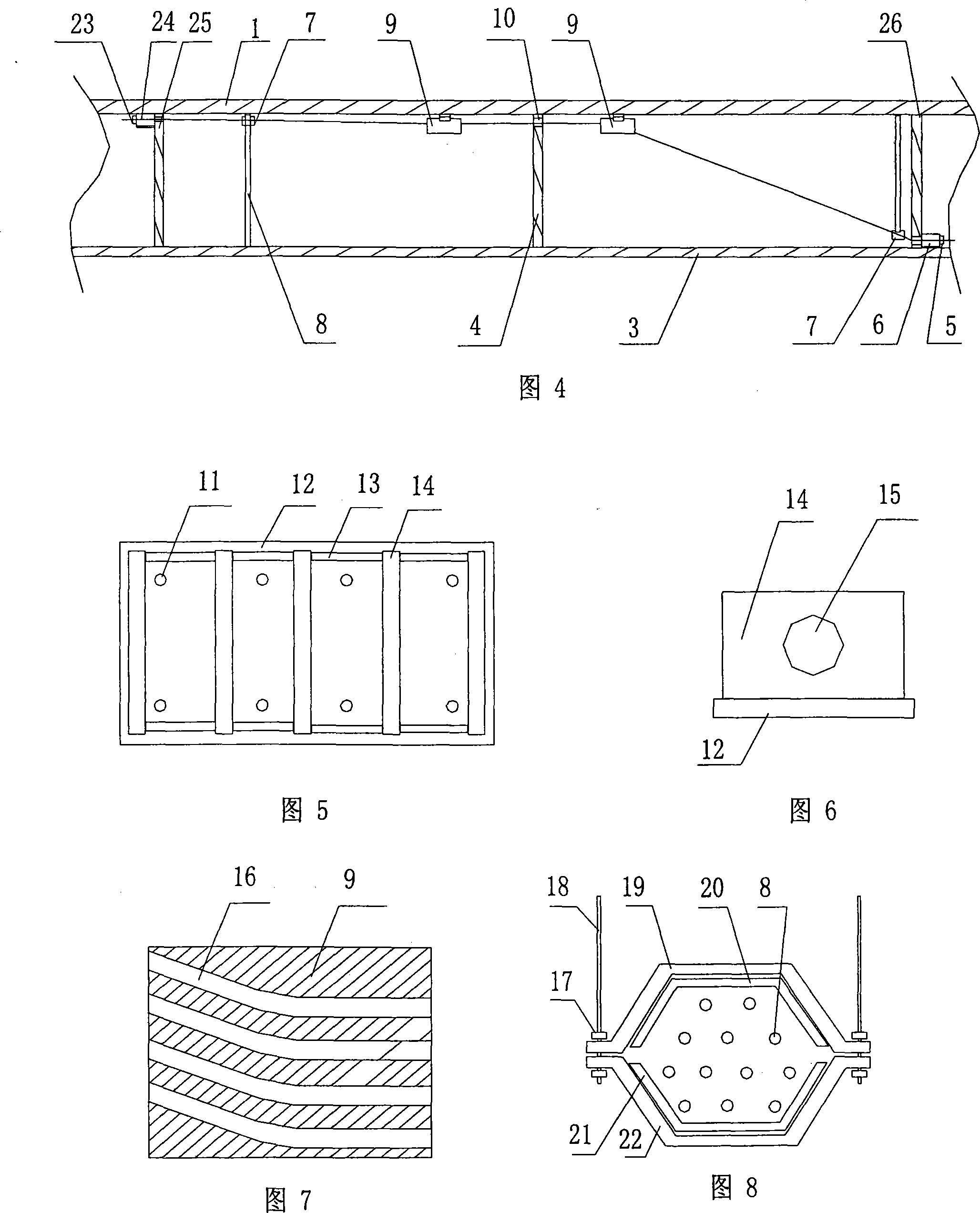

[0040] The maintenance of a large bridge in Wuhan adopts external prestressing technology to reinforce the bridge. A total of 40 external cables are designed, and each external cable has 12 steel strands. The layout of external cables is shown in the schematic diagram of external cable layout (Figure 1, Figure 2, Figure 3). , as shown in Figure 4, Note: There are more than these three types of external cable arrangements).

[0041] External prestressing arrangement:

[0042] 1. 13 # ~16 # The external prestressing arrangement of the upstream and downstream boxes of the continuous rigid frame of the pier:

[0043] (1), 13 # ~16 # The external prestressed beams of the continuous rigid frame of the pier are arranged with 4 beams per box with a span of 83m and a span of 130m. 8 beams are arranged across 125m, of which 4 beams and 4 beams across 130m are common beams.

[0044] (2) As shown in Figure 3, the 83m cross-body bundle is at 16 # Fixed at the bottom plate of the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com