Anchor rod gravity retaining wall for high slope support and manufacturing method

A production method and gravity-based technology, applied in excavation, water conservancy projects, artificial islands, etc., to achieve the effects of convenient construction, clear force and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

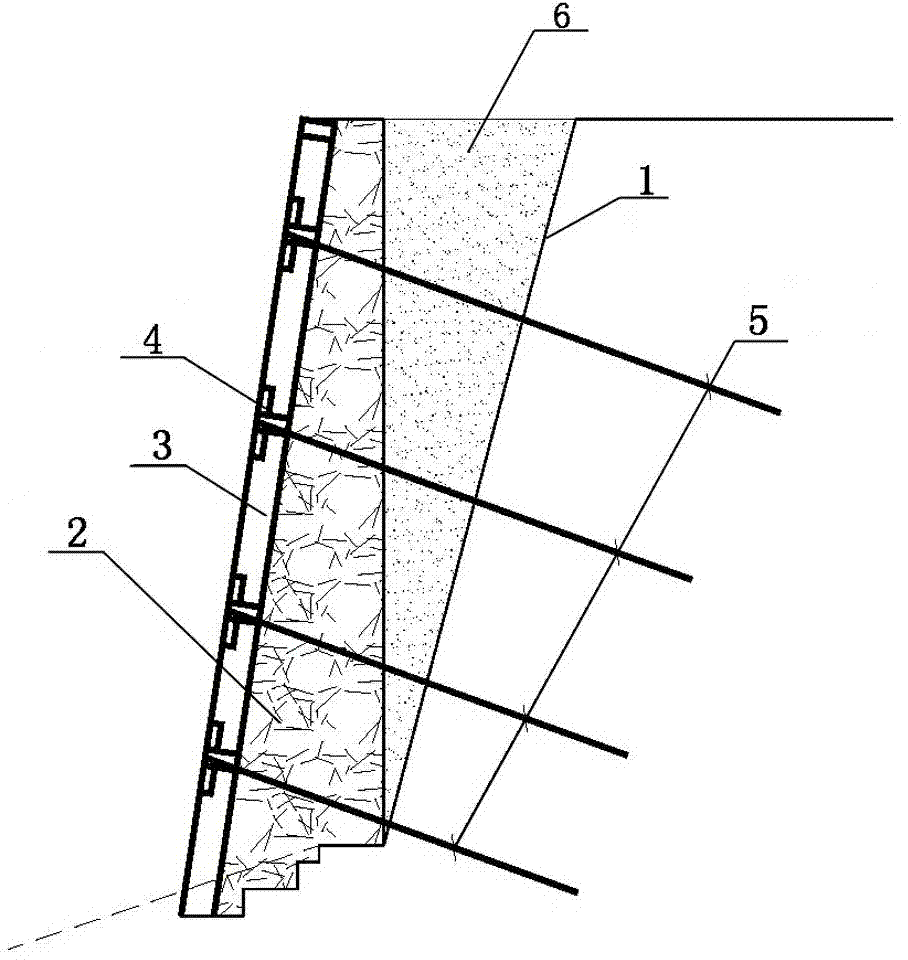

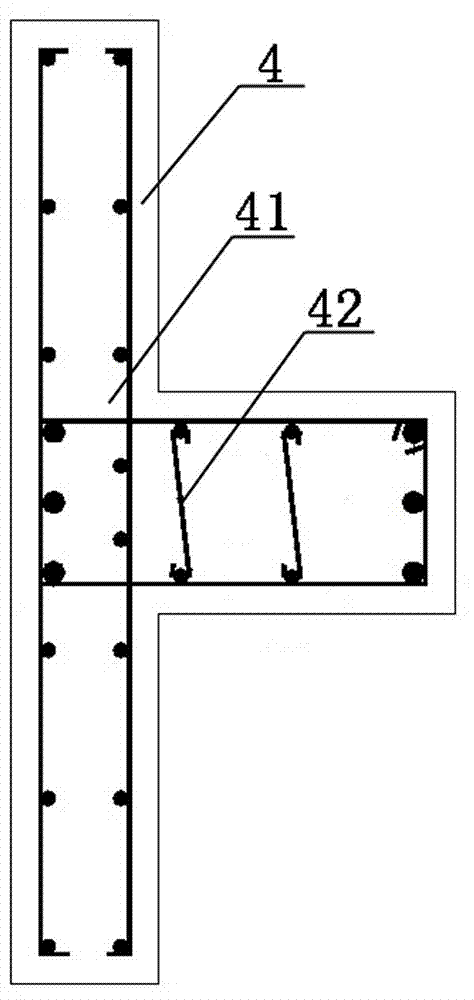

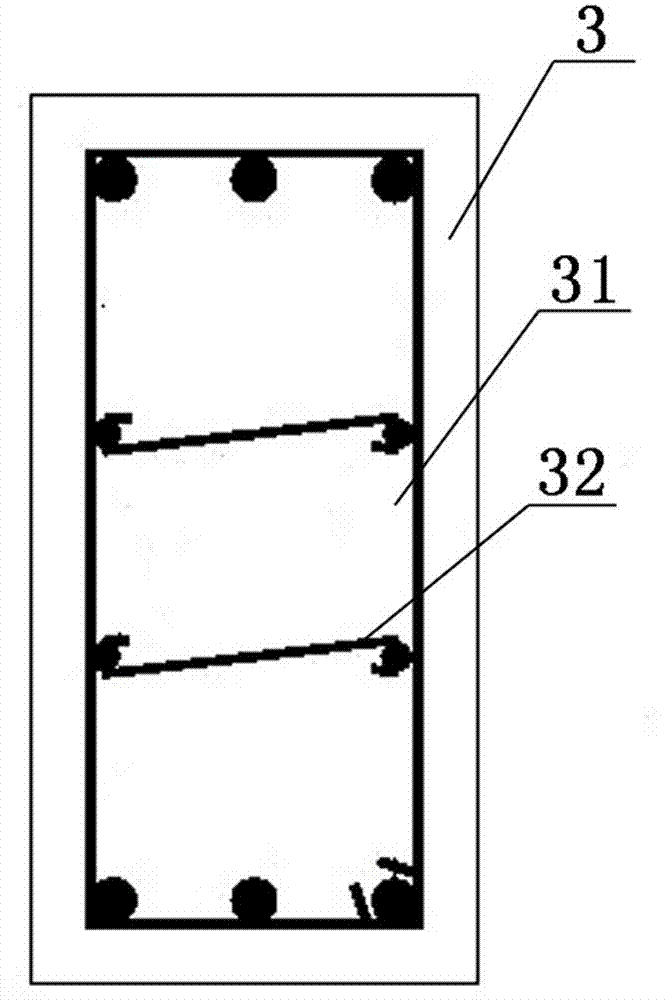

[0023] The present invention will be described in detail below in conjunction with accompanying drawing namely embodiment: Figure 1-4 As shown, a kind of anchor gravity retaining wall used for high slope support according to the present invention, wherein the high slope includes a rock face 1 forming a steep terrain, and the anchor gravity retaining wall It includes a stone retaining wall 2 close to the rock face 1, and a reinforced concrete slab 4 with a reinforced concrete rib column 3 is formed on the outer surface of the stone retaining wall 2; 4 is connected with a plurality of connecting anchor rods 5 that pass through the stone retaining wall 2 obliquely inwardly and are directly inserted into the rock face 1 .

[0024] As shown in the figure, the reinforced concrete slab 4 is embedded in the stone retaining wall 2 through the connected reinforced concrete rib column 3 and is closely connected with the stone retaining wall 2, and the reinforced concrete slab 4 is A ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com