Assembly type laminated slab installing and locating method

An installation method and a technology of laminated slabs, which are applied to floors, building components, buildings, etc., can solve the problems of not being able to eliminate cracks in reinforced concrete slabs, negative impacts on safety at cracks, and increased consumption of steel bars, achieving high rigidity and increased consumption of steel bars , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

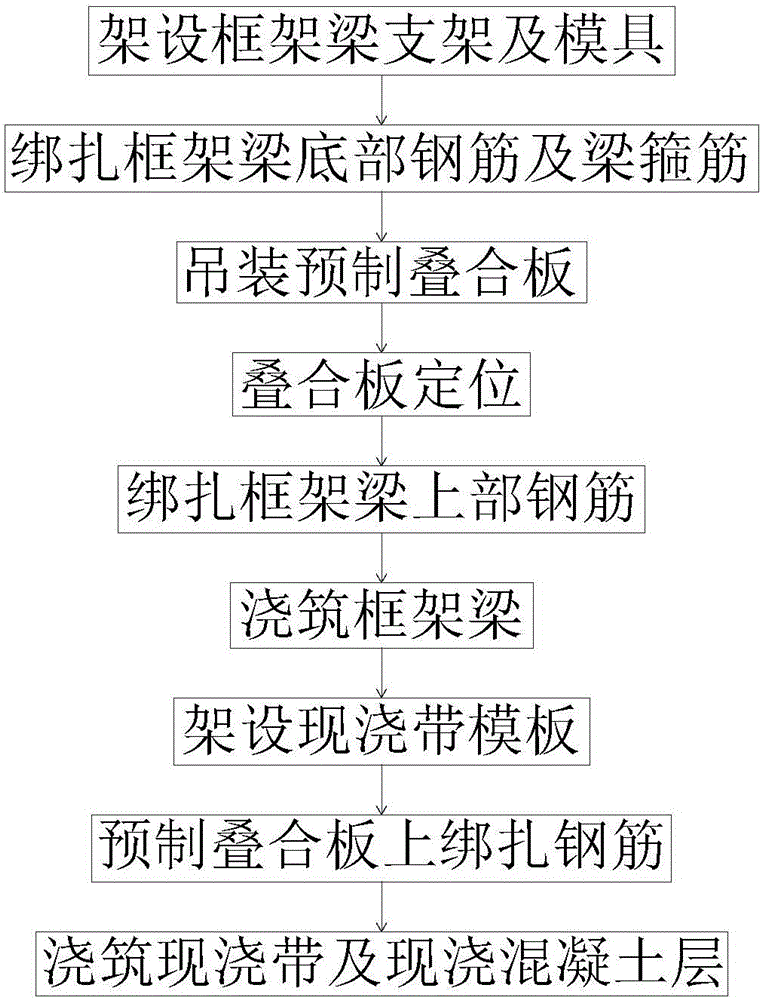

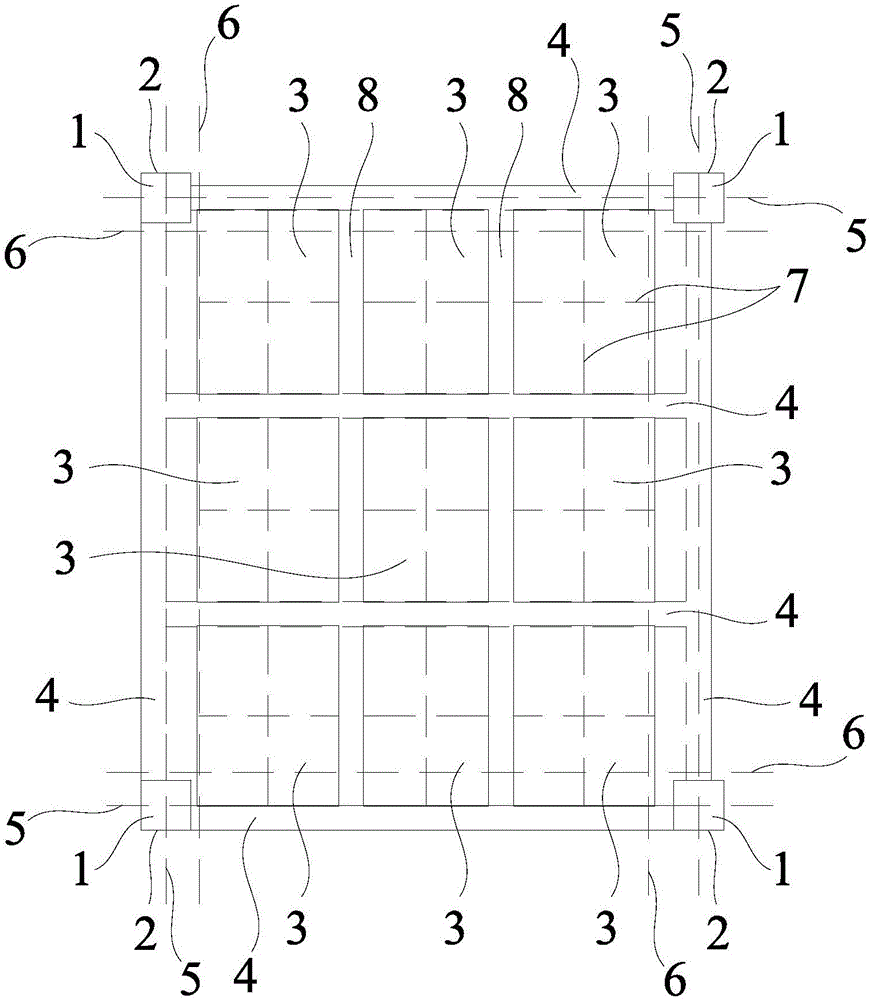

[0075] Such as Figure 1-8 As shown, a method for installing a prefabricated laminated panel according to the present invention includes the following steps:

[0076] A. Erection of frame beam 4 brackets and molds from the lower floor;

[0077] B, binding the bottom steel bar 42 and the beam stirrup 43 of the frame beam 4;

[0078] C, hoisting all prefabricated laminated panels 3 so that their ends are set at the midline of the frame beam 4;

[0079] D, positioning all the prefabricated laminated panels 3;

[0080] E, binding the upper reinforcement 41 of the frame beam 4;

[0081] F, pouring the frame beam 4;

[0082] G. Formwork 9 is set below the gap area between two adjacent prefabricated laminated panels 3, and the template 9 is supported by a support system 93 erected on the lower floor. The side walls of the two prefabricated laminated panels 3 are connected to The template 9 forms a cast-in-place belt 8;

[0083] H, binding the negative moment reinforcement and s...

Embodiment 2

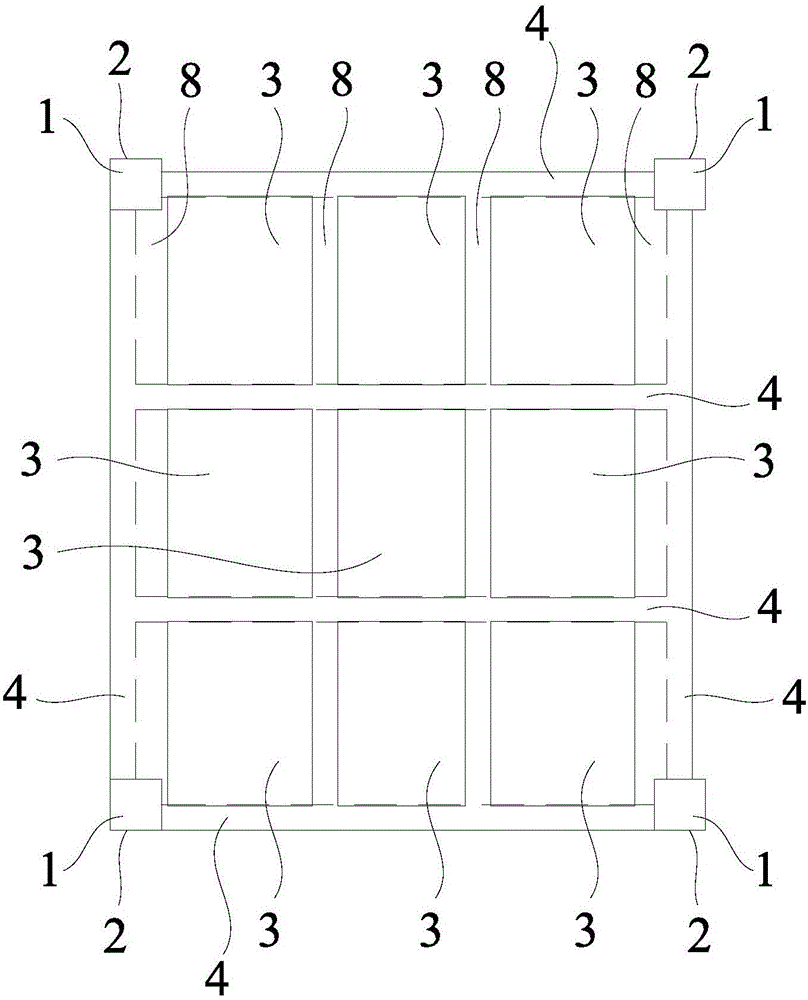

[0105] Such as Figure 2-9 As shown, a method for locating assembled laminated panels according to the present invention includes the following steps:

[0106] 1. Install the positioning stirrups 2 with a diameter of 20mm on all the frame column steel bars 11 on each floor;

[0107] II. Lead each reference control axis 5 on the ground floor to each floor, and mark the position of each axis 5 on the corresponding positioning stirrup 2;

[0108] III. Release all the axes 5, and check the distance and angle between each axis 5 on all frame columns 1 to meet the design requirements;

[0109] Ⅳ. Pop out its two centerlines 7 on each prefabricated panel 3 with a number;

[0110] V. According to the positional relationship between each center line 7 and the corresponding axis 5 in the design requirements, each center line 7 is bounced on the corresponding frame beam 4 side formwork;

[0111] VI. According to the design requirements, install the prefabricated panels 3 with correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com