Hybrid frp-concrete-steel double-skin tubular beams and hybrid dstb/slab units using the beams

a technology of concrete-steel and double-skin tubular beams, which is applied in the direction of pillars, structural elements, building components, etc., can solve the problems of high cost, poor corrosion resistance of beam forms, and prone to deterioration and corrosion of both beam forms, so as to achieve excellent corrosion resistance and cost-effective effect, less frp material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

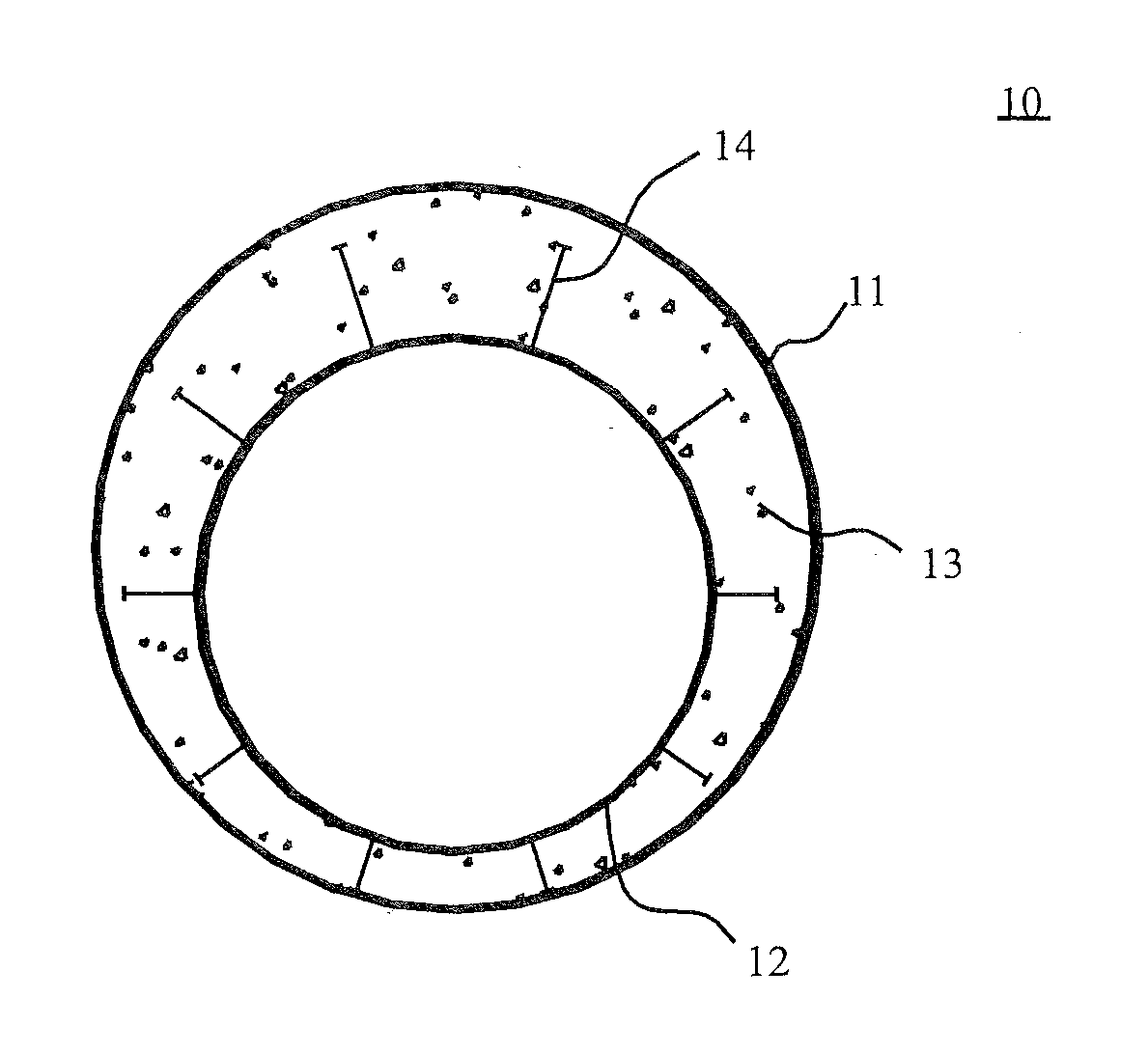

[0023]FIG. 1 depicts the cross sectional structure of the hybrid double-skin tubular beam 10 according to the invention. As shown in FIG. 1, the hybrid double-skin tubular beam 10 is a beam form in the shape of a hollow cylinder, consisting of a circular outer tube 11 made of fiber-reinforced polymer, a circular inner tube 12 made of steel, and concrete 13 filled between the outer tube 11 and the inner tube 12. The outer FRP tube 11 and the inner steel tube 12 are not deployed coaxially in such a way that the inner steel tube 12 shifts a distance towards the side of the hybrid tubular beam 10 that would be tensed. As such, the steel tube can be fully exploited to behave as a material to be longitudinally tensed due to its good ductility. Furthermore, the inner steel tube 12 is provided with a plurality of shear connectors 14 on its side engaged with concrete, which not only ensure the composite action between the inner steel tube 12 and the concrete 13, but also act as positioning s...

second embodiment

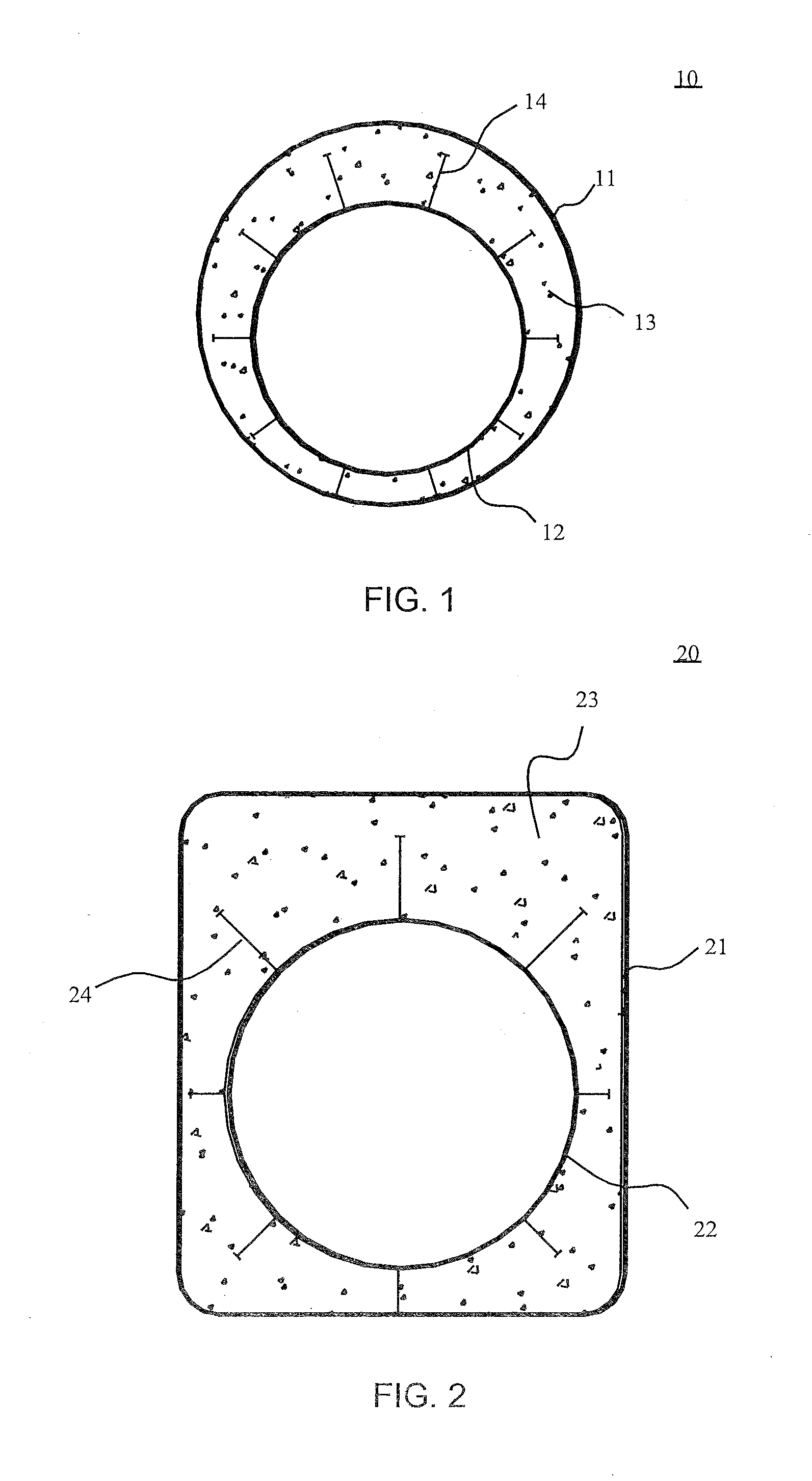

[0024]FIG. 2 depicts the cross sectional structure of the hybrid double-skin tubular beam 20 according to the invention. The hybrid double-skin tubular beam 20 is a beam form in the shape of a hollow rectangular column. Its structure is similar to that of the hybrid double-skin tubular beam 10. As particularly shown in FIG. 2, the hybrid double-skin tubular beam 20 consists of a rectangular outer FRP tube 21, a circular inner steel tube 22, and concrete 23 filled between the outer tube 21 and the inner tube 22. Similarly, the inner steel tube 22 shifts, with respect to the outer FRP tube 21, a distance towards the side of the hybrid tubular beam 20 that would be tensed. As such, the steel tube can be fully exploited to behave as a material to be longitudinally tensed due to its good ductility. Furthermore, the inner steel tube 22 is circumferentially provided with a plurality of shear connectors 24 on its side engaged with concrete, which, on the one hand, ensure the composite actio...

third embodiment

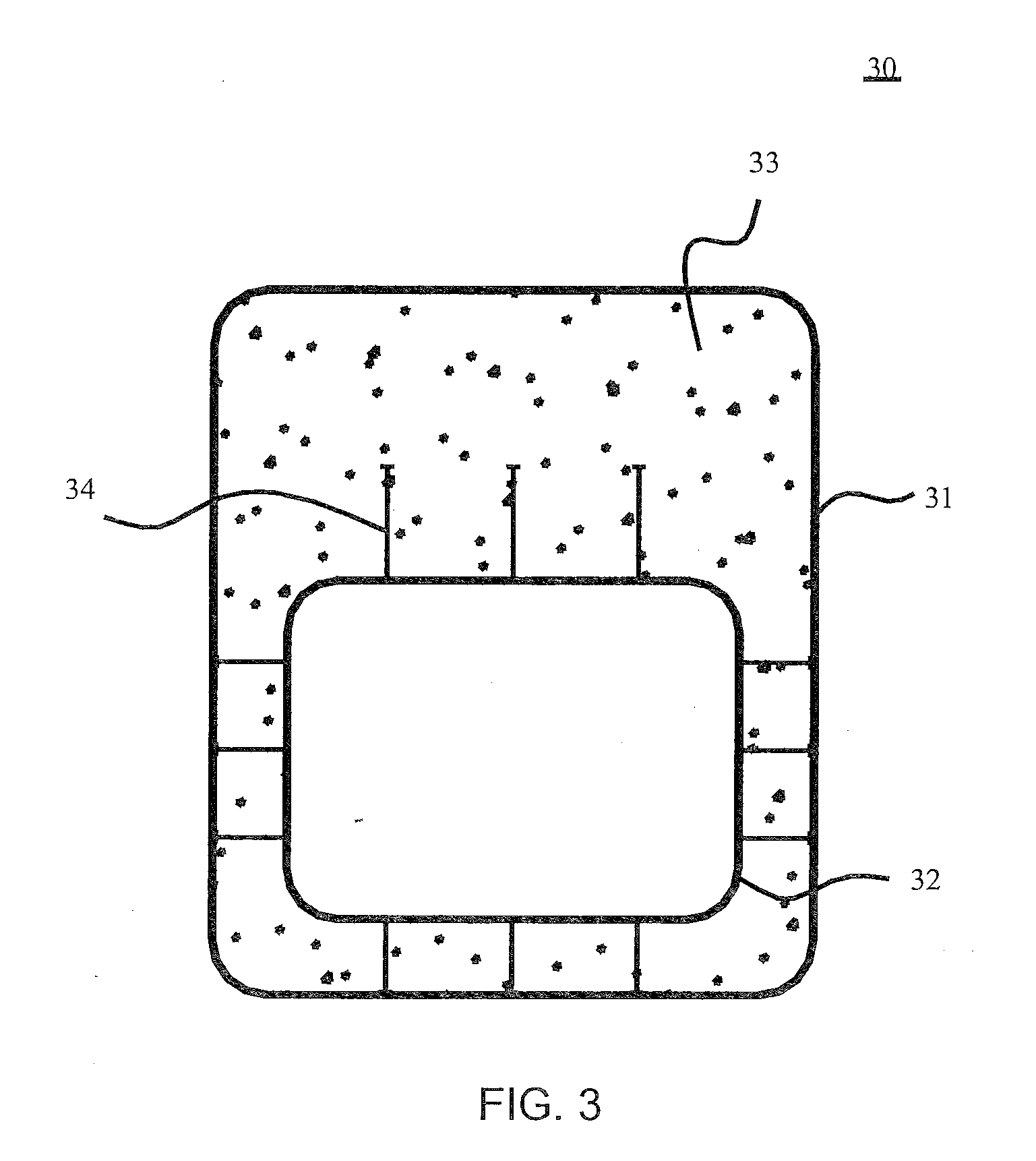

[0025]FIG. 3 depicts the cross sectional structure of the hybrid double-skin tubular beam 30 according to of the invention. The hybrid double-skin tubular beam 30 is a beam form in the shape of a hollow rectangular column. Its structure is similar to those of the hybrid double-skin tubular beam 10 as shown in FIG. 1 and the hybrid double-skin tubular beam 20 as shown in FIG. 2. As particularly shown in FIG. 3, the hybrid double-skin tubular beam 30 consists of a rectangular outer FRP tube 31, a rectangular inner steel tube 32, and concrete 33 filled between the outer tube 31 and the inner tube 32. Similarly, the inner steel tube 32 shifts, with respect to the outer FRP tube 31, a distance towards the side of the hybrid tubular beam 30 that would be tensed. As such, the steel tube can be fully exploited to behave as a material to be longitudinally tensed due to its good ductility. Furthermore, the inner steel tube 32 is circumferentially provided with a plurality of shear connectors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com