Abutting joint device of steel lattice column, and construction method of same

A technology of steel lattice column and docking installation, which is applied in basic structure engineering, excavation, building construction, etc. And the effect of construction quality, easy construction operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

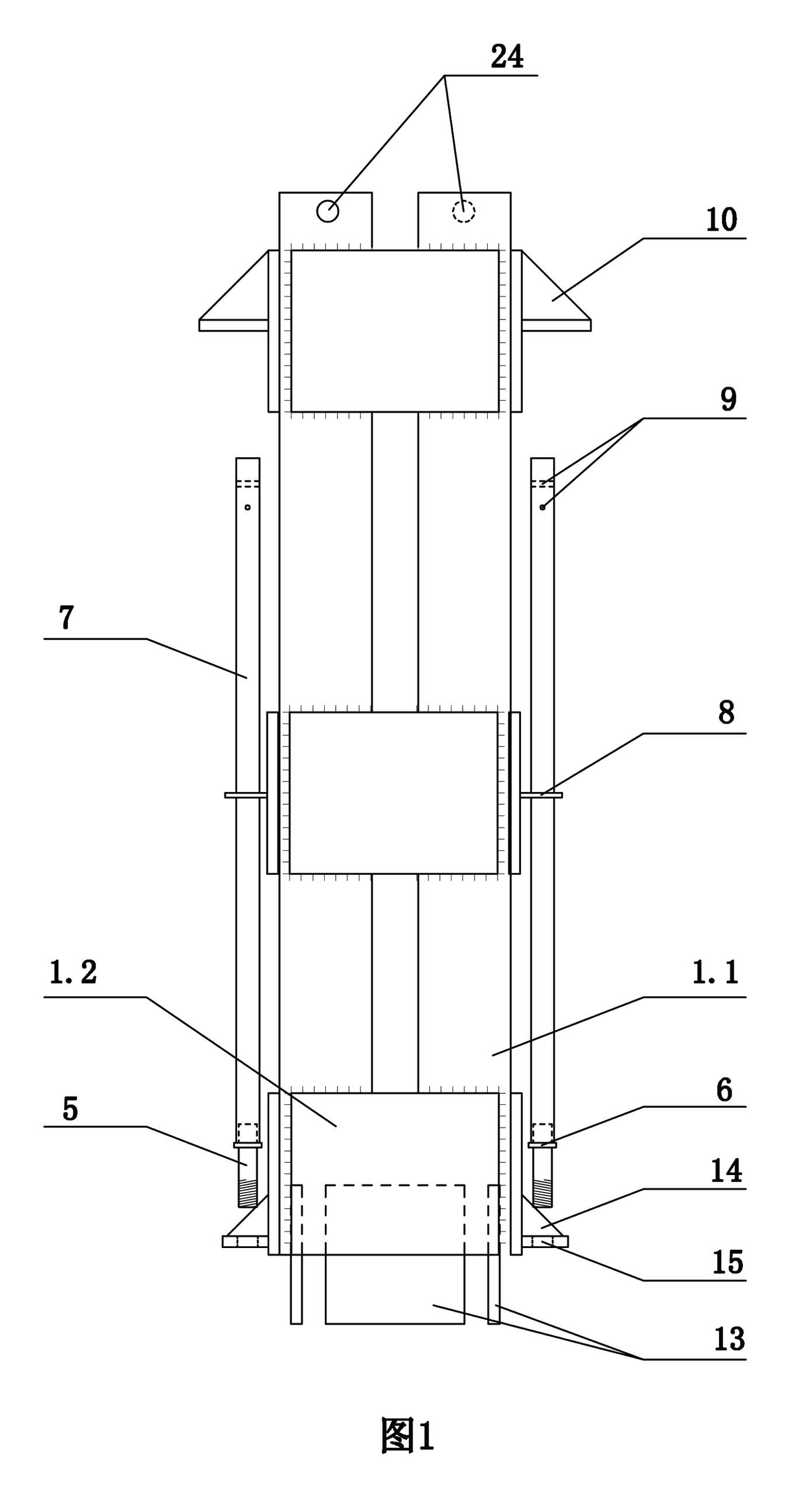

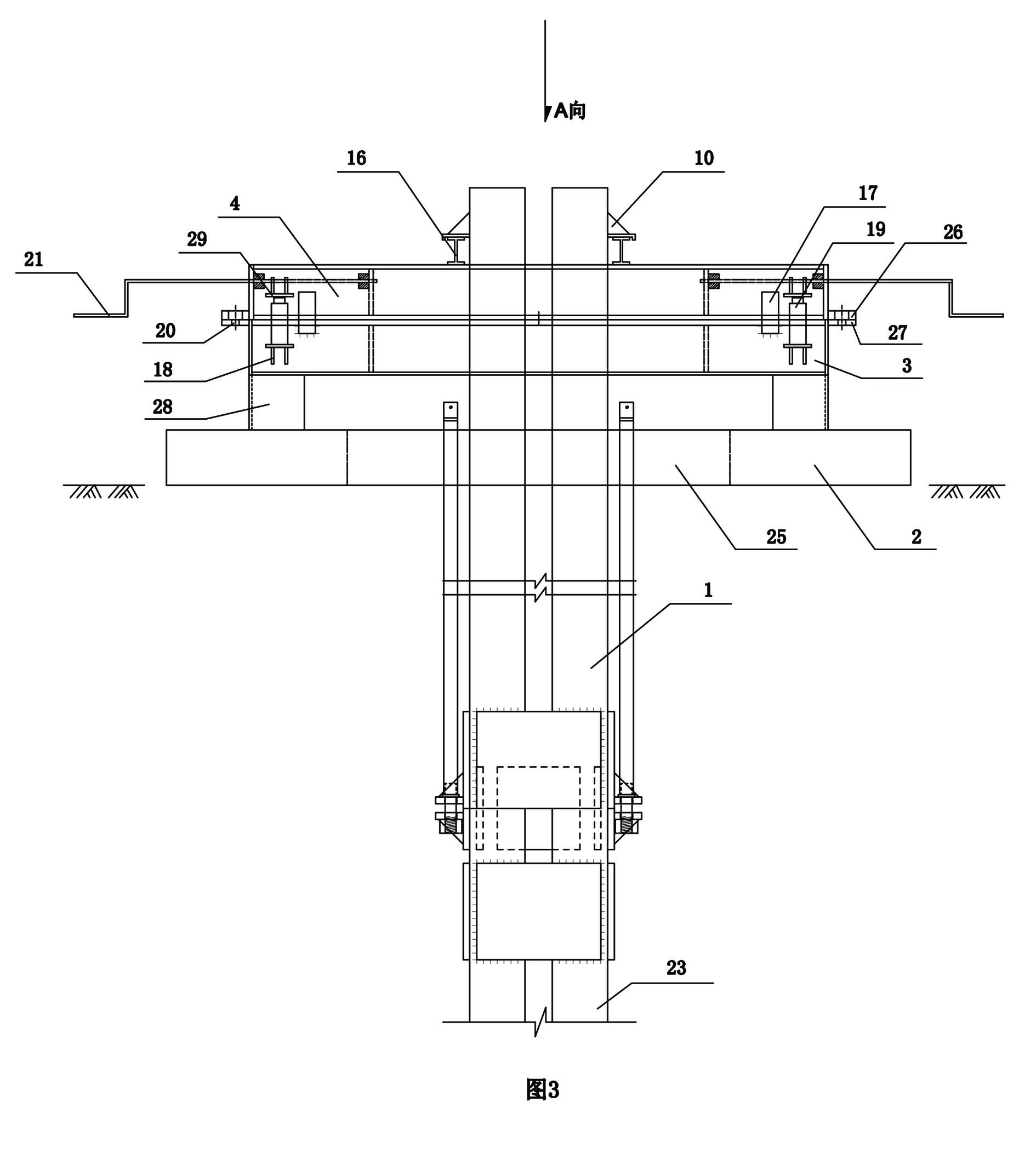

[0040] Examples see Figure 1-4 as shown,

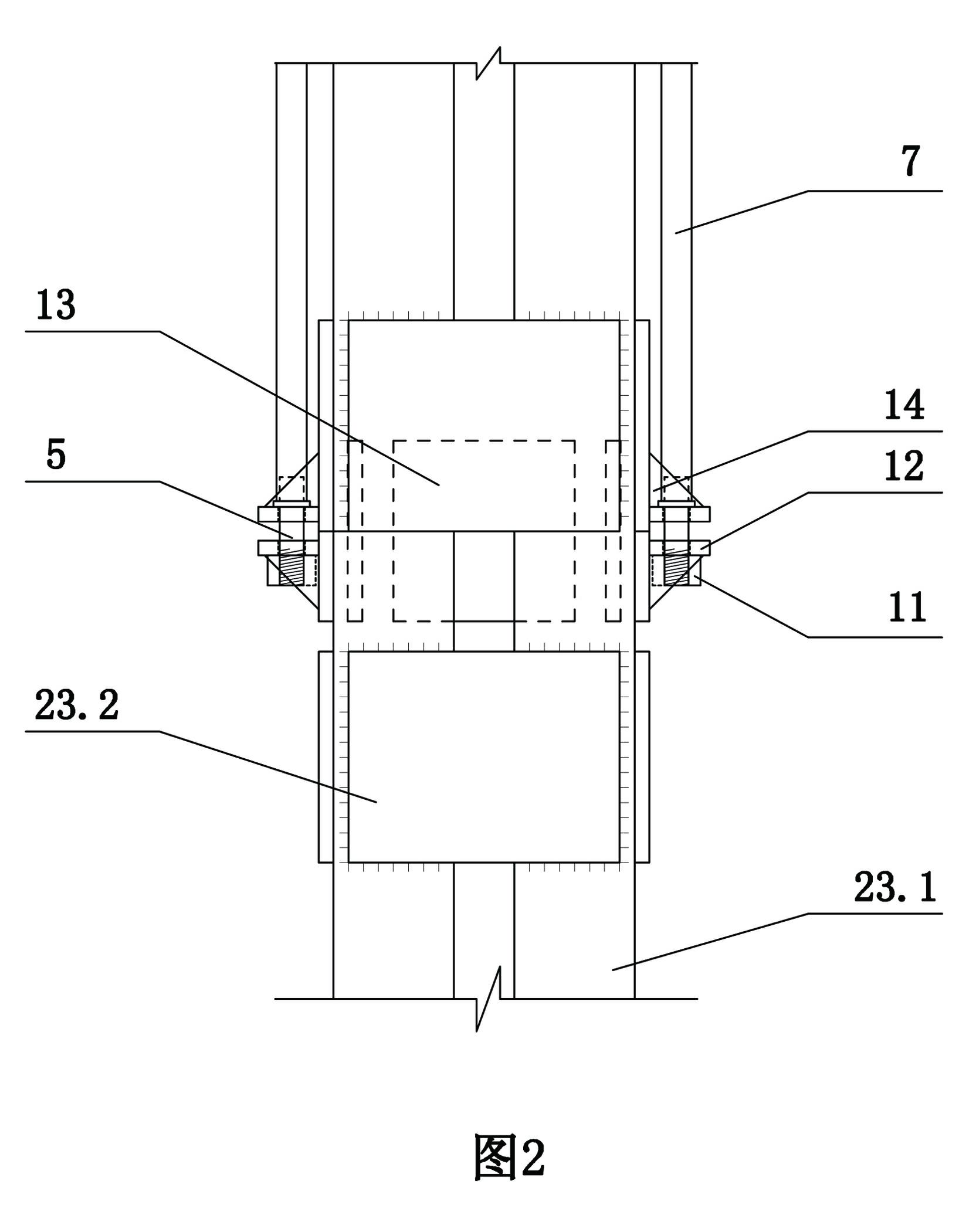

[0041] A butt joint installation device for a steel lattice column, comprising a steel lattice column 23 composed of four angle steel limbs 23.1 and decorative plates 23.2 welded around the four angle steel limbs at intervals, the steel lattice column 23 The upper end of the joint 1 is connected with the joint 1, and the upper end of the joint 1 is connected with the locator;

[0042] Two limit corbels 12 are welded on the uppermost panels on the left and right sides of the steel lattice column 23, each limit corbel has a perforation, and a nut 11 is welded below the perforation.

[0043] The movable joint 1 is connected as a rigid body by four shaped steel columns 1.1 and surrounding steel parts 1.2 welded at intervals around the four shaped steel columns. The left and right sides of the rigid body are symmetrical structures, and the surrounding steel parts on the left and right A row of stirrup rings 8 are welded on the top, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com