Method for assembling building

A construction method and building technology, applied in the field of building construction, can solve problems such as monotonous appearance, and achieve the effect of simple assembly work, high interior decoration requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

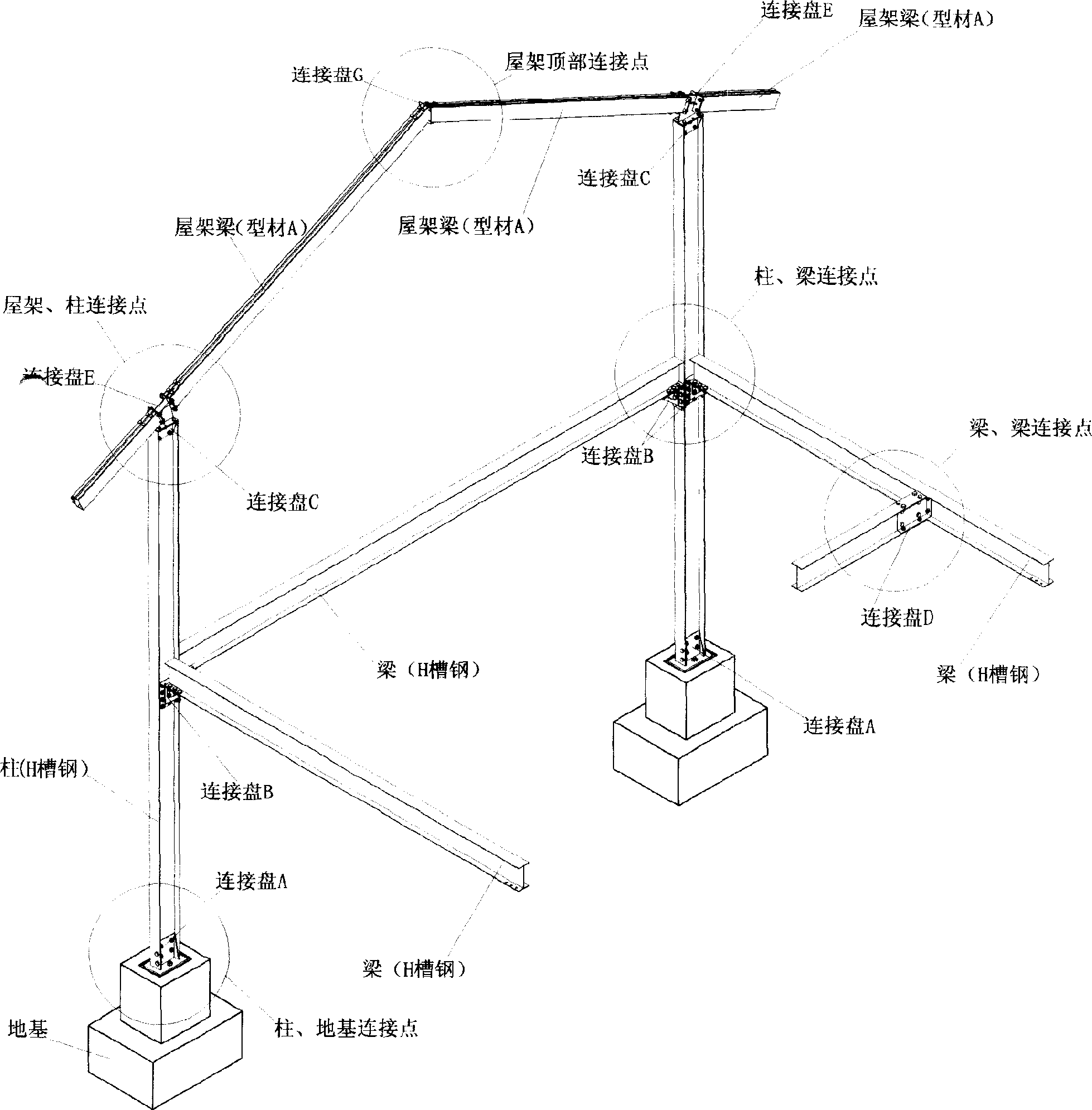

[0032] figure 1 Indicates: the main frame of the building assembled with H channel steel after cutting and drilling, roof truss beams made of profile A, various types of connection plates and bolts.

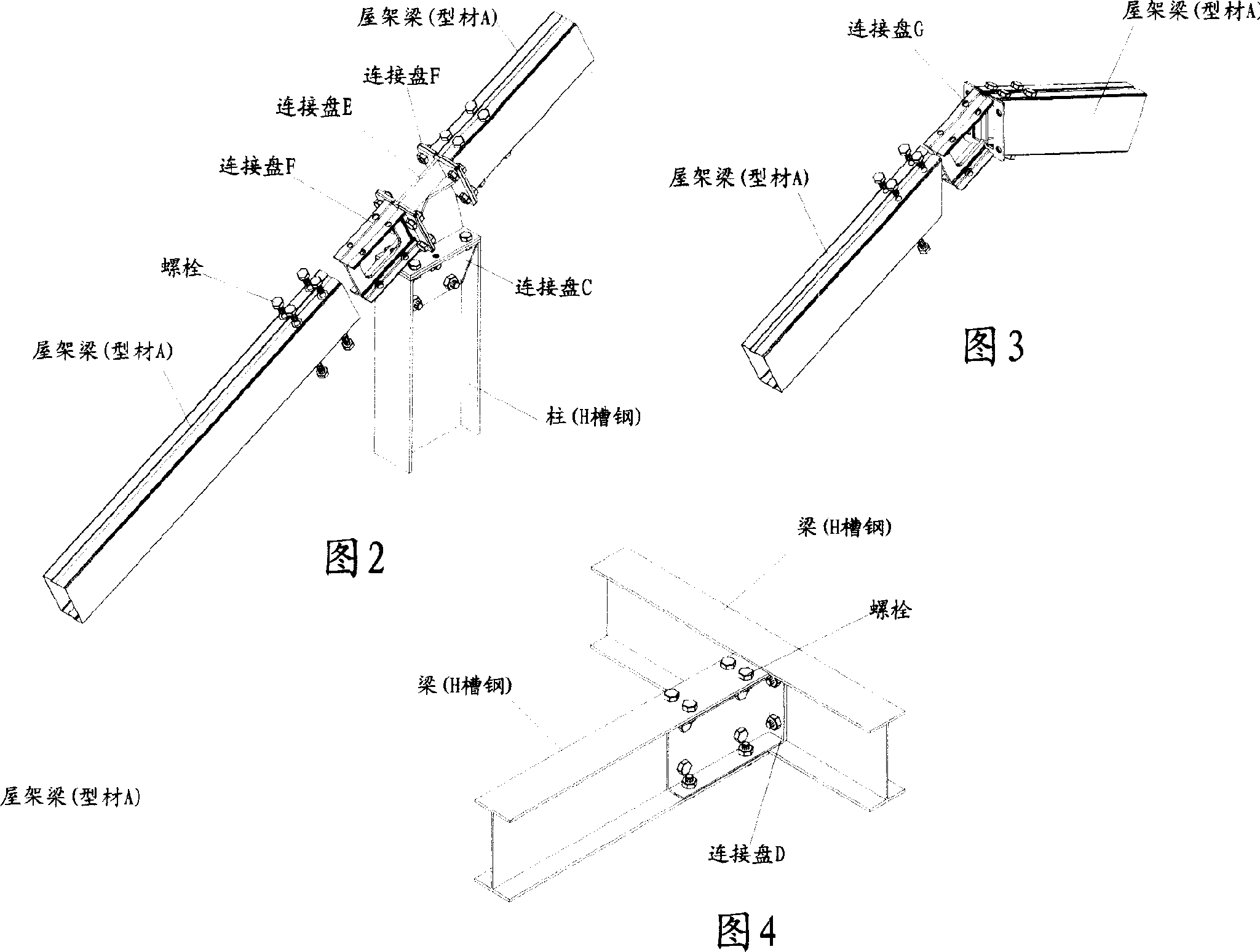

[0033] Fig. 2 shows: the roof truss assembled with the section bar A which has been drilled, the connecting plate F and the connecting plate E; with the connecting plate C, the roof truss and the column can be connected.

[0034] Fig. 3 is a joint diagram at the top corner of the roof truss: the corner of the roof truss beam is formed by connecting the profile A, the connecting plate G and the bolts with the ends cut to a certain angle and drilled.

[0035] Fig. 4 shows: with the connecting plate D and high-strength bolts, the beams made of H channel steel with holes can be connected into one.

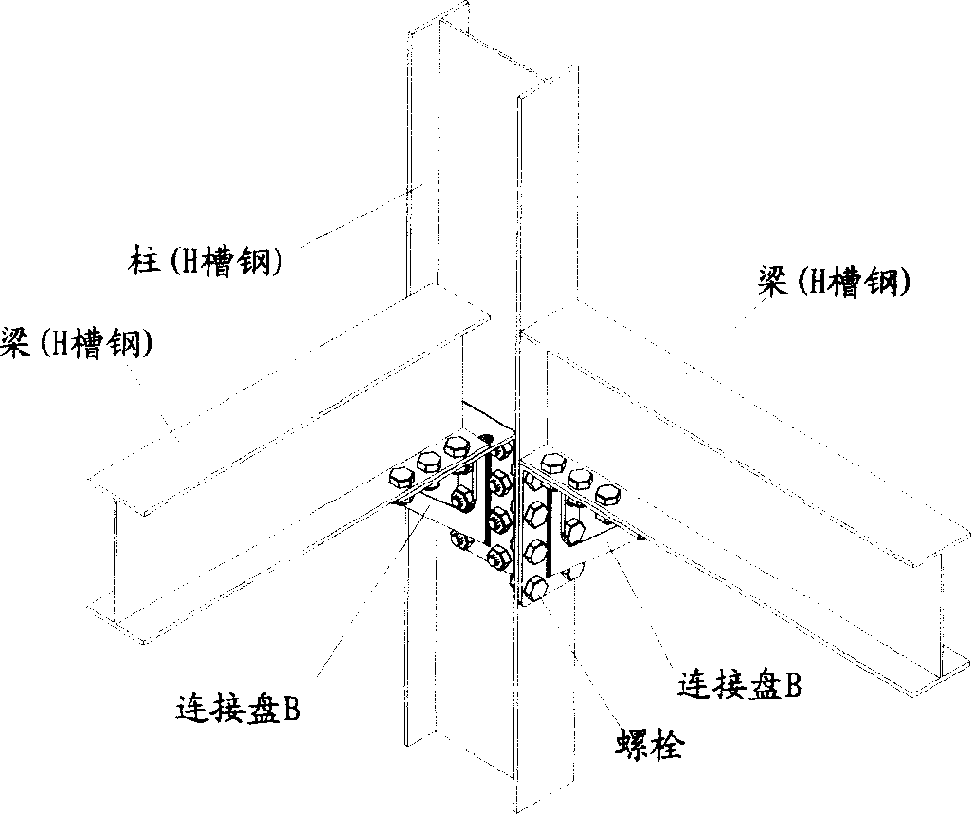

[0036] Figure 5 Indicates that beams and columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com