A method and application of large-scale continuous production of three-dimensional graphene film

A graphene film, graphene technology, applied in the direction of titanium dioxide, ferrous oxide, titanium oxide/hydroxide, etc., can solve the problem of limited scale, continuous production, and difficult application and preparation of three-dimensional graphene Harsh conditions and other problems, to achieve the effect of low price, light quality and fast restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Utilize the oxidized exfoliated graphite method (Hummers method) to prepare 10mg / mL graphene oxide solution;

[0062] 2. Heat, stir and concentrate the 10mg / mL graphene oxide solution at 45°C, so that the concentration of the graphene oxide solution is 25mg / mL;

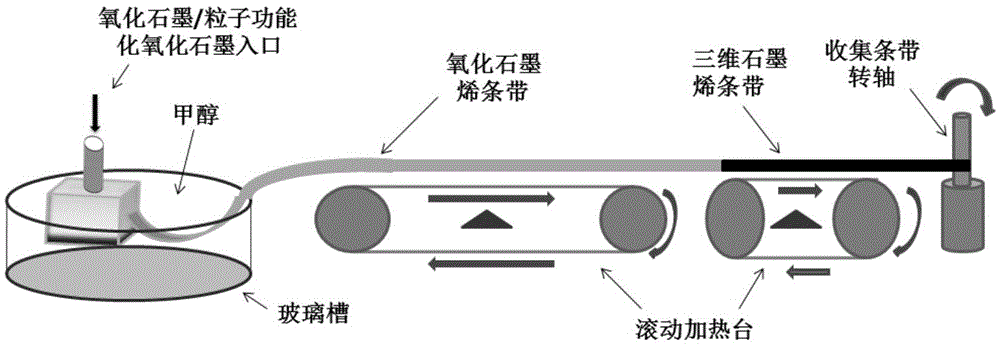

[0063] 3. Immerse a polytetrafluoroethylene tank with a top opening (3cm in diameter) and a square notch on one side of the bottom into a glass tank filled with methanol, and the notch is completely immersed in methanol. The height of the square notch is 0.4cm, and the width is 3cm;

[0064] 4. In the second step, the concentrated 25mg / mL graphene oxide solution is injected from the top of the polytetrafluoroethylene tank, so that the graphene oxide solution is pushed out from the bottom slot at a speed of 0.8m / min and formed in the methanol solution. A continuous ribbon structure of graphene oxide, i.e. graphene oxide ribbons;

[0065] 5. Lead the punched graphene oxide strips from the methanol solution t...

Embodiment 2

[0070] 1. Utilize the oxidized exfoliation graphite method (Hummers method) to prepare 4mg / mL graphene oxide solution;

[0071] 2. Heat, stir and concentrate the 4mg / mL graphene oxide solution at 60°C, so that the concentration of the graphene oxide solution is 15mg / mL;

[0072] 3. Immerse a polytetrafluoroethylene tank with a top opening (3cm in diameter) and a square notch on one side of the bottom into a glass tank filled with methanol, and the notch is completely immersed in methanol. The height of the square notch is 0.3cm, and the width is 2cm;

[0073] 4. In the second step, the concentrated 15mg / mL graphene oxide solution is injected from the top of the polytetrafluoroethylene tank, so that the graphene oxide solution is pushed out from the bottom slot at a speed of 0.8m / min and formed in the methanol solution. A continuous ribbon structure of graphene oxide, i.e. graphene oxide ribbons;

[0074] 5. Lead the graphene oxide strips from the methanol solution to a 60°C,...

Embodiment 3

[0078] 1. Utilize the oxidized exfoliation graphite method (Hummers method) to prepare 8mg / mL graphene oxide solution;

[0079] 2. Heat, stir and concentrate the 8mg / mL graphene oxide solution at 50°C, so that the concentration of the graphene oxide solution is 20mg / mL;

[0080] 3. Immerse the polytetrafluoroethylene tank with an open top (3cm in diameter) and a square notch on one side of the bottom into a glass tank filled with methanol, and the notch is completely immersed in methanol; the height of the square notch is 0.5cm, width 6cm;

[0081] 4. In the second step, the concentrated 20mg / mL graphene oxide solution is injected from the top of the polytetrafluoroethylene tank, so that the graphene oxide solution is pushed out from the bottom slot at a speed of 0.8m / min and formed in the methanol solution. A continuous ribbon structure of graphene oxide, i.e. graphene oxide ribbons;

[0082] 5. Lead the punched graphene oxide strips from the methanol solution to a 50°C, 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com