Graphene oxide fiber and preparation method and application thereof

A graphene fiber, graphene layer technology, applied in the chemical characteristics of fibers, control of mechanical energy, textiles and papermaking, etc., to achieve the effects of high quality, wide sources, and mature synthesis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Prepare a 6 mg / mL graphene oxide solution using the oxidized exfoliated graphite method (Hummers method);

[0033] 2. Concentrate the 6mg / mL graphene oxide solution at a temperature of 30-35°C, so that the concentration of the graphene oxide solution is 15mg / mL;

[0034] 3. Pour the 15mg / mL graphene oxide solution into the syringe, and the inner diameter of the syringe needle is 0.21mm.

[0035] 4. Use the above-mentioned syringe equipped with 15 mg / mL graphene oxide solution to continuously and uniformly inject the graphene oxide solution into the saturated potassium chloride methanol solution through a syringe with an inner diameter of 0.21 mm to obtain continuous linear graphene oxide gel fibers .

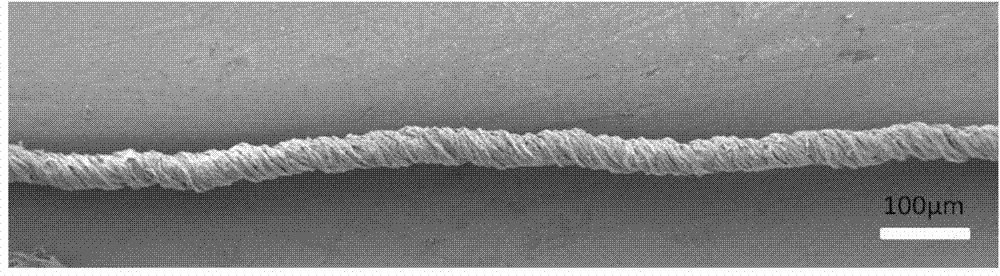

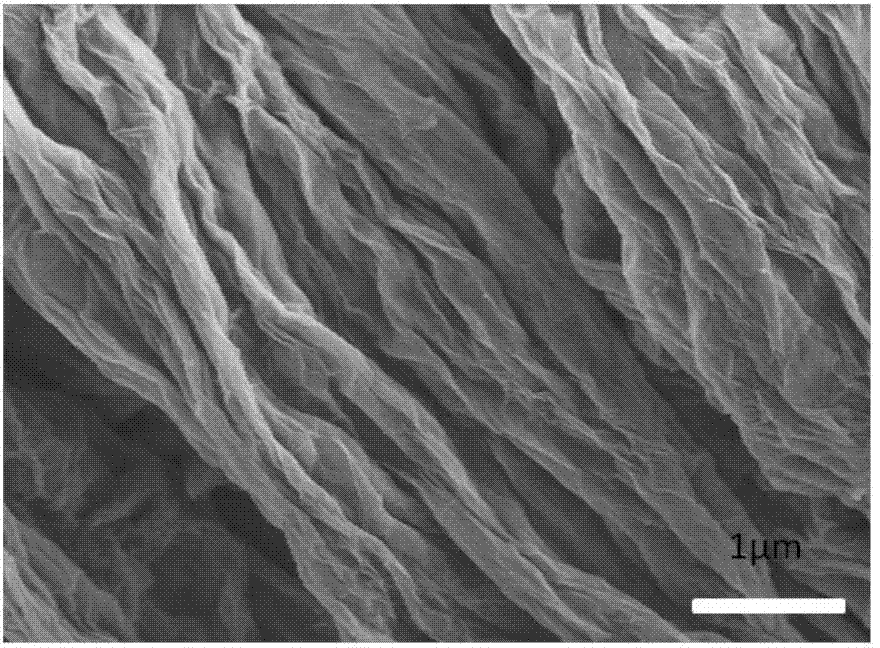

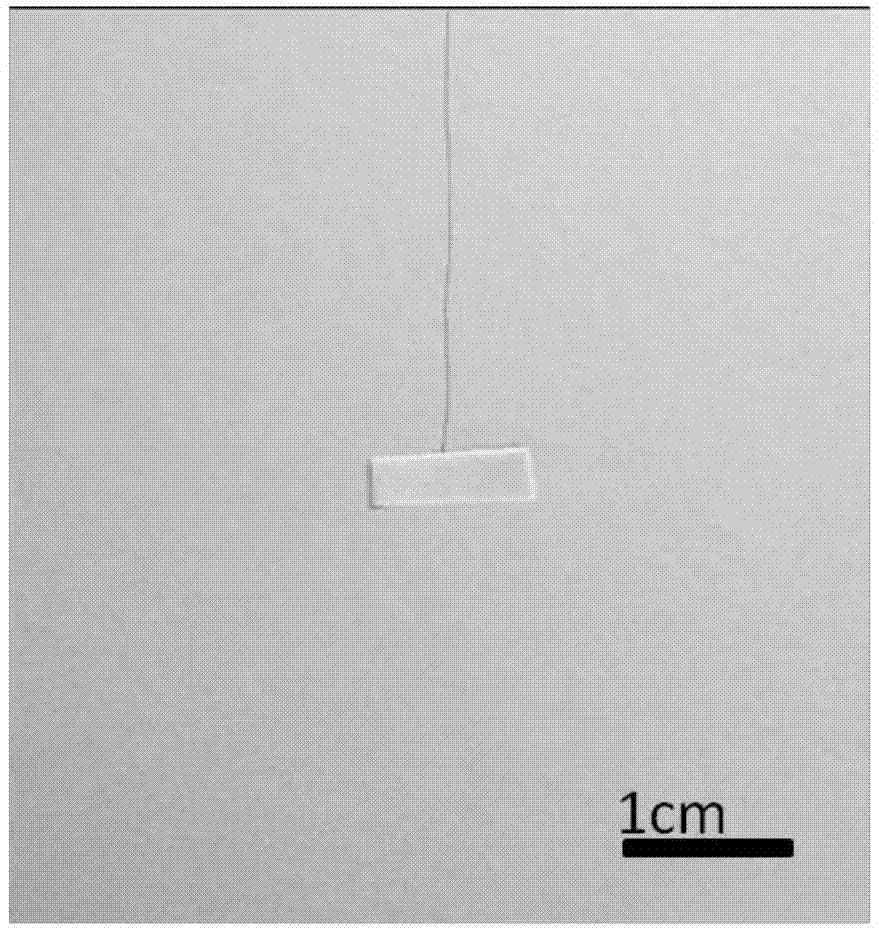

[0036] 5. Take the graphene oxide gel fiber, fix one end, and use the motor to rotate the other end, process 5000 revolutions per meter of graphene oxide fiber, dry the fiber naturally after processing, and perform characterization analysis on the obtained product , ...

Embodiment 2

[0040] 1. Prepare a 2 mg / mL graphene oxide solution using the oxidized exfoliated graphite method (Hummers method);

[0041]2. Concentrate the 2mg / mL graphene oxide solution at a temperature of 30-35°C, so that the concentration of the graphene oxide solution is 15mg / mL;

[0042] 3. Pour the 15mg / mL graphene oxide solution into the syringe, and the inner diameter of the syringe needle is 0.21mm.

[0043] 4. Use the above-mentioned syringe equipped with 15 mg / mL graphene oxide solution to continuously and uniformly inject the graphene oxide solution into the saturated potassium chloride methanol solution through a syringe with an inner diameter of 0.21 mm to obtain continuous linear graphene oxide gel fibers .

[0044] 5. Take the graphene oxide gel fiber, fix one end, and use the motor to rotate the other end, processing 1000 revolutions per meter of graphene oxide fiber. After processing, the fibers were dried naturally, and the resulting product was characterized and analy...

Embodiment 3

[0048] 1. Prepare a 10 mg / mL graphene oxide solution using the oxidized exfoliated graphite method (Hummers method);

[0049] 2. Concentrate the 10mg / mL graphene oxide solution at a temperature of 30-35°C, so that the concentration of the graphene oxide solution is 15mg / mL;

[0050] 3. Pour the 15mg / mL graphene oxide solution into the syringe, and the inner diameter of the syringe needle is 0.21mm.

[0051] 4. Use the above-mentioned syringe equipped with 15 mg / mL graphene oxide solution to continuously and uniformly inject the graphene oxide solution into the saturated potassium chloride methanol solution through a syringe with an inner diameter of 0.21 mm to obtain continuous linear graphene oxide gel fibers .

[0052] 5. Take the graphene oxide gel fiber, fix one end, and use the motor to rotate the other end, processing 2000 revolutions per meter of graphene oxide fiber. After processing, the fibers were dried naturally, and the resulting product was characterized and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com