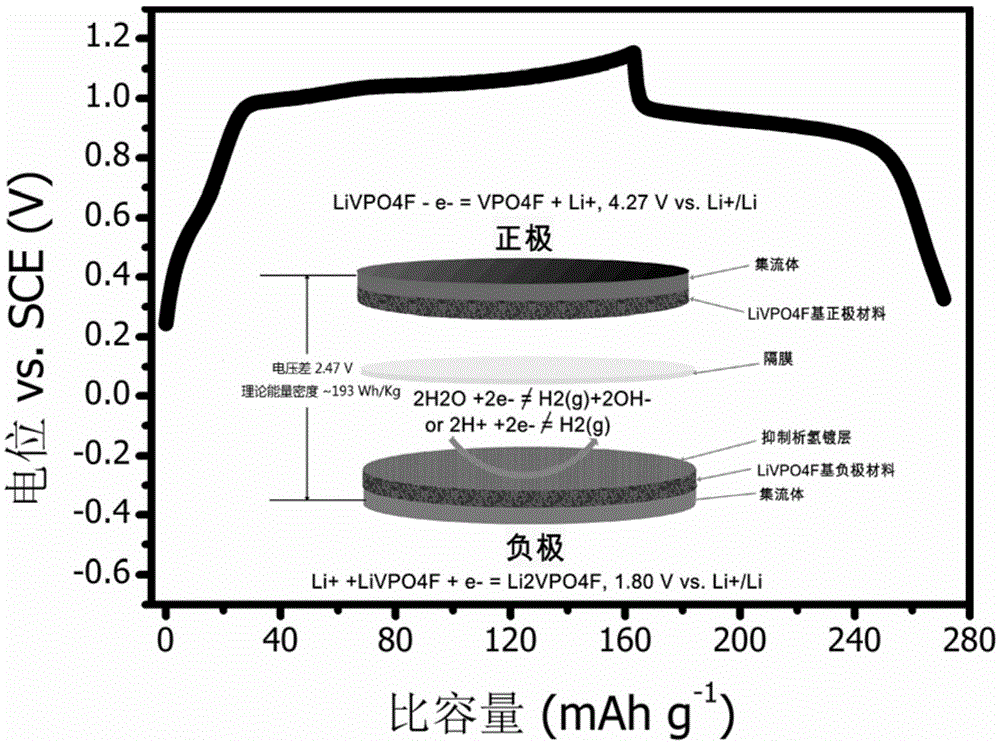

A symmetrical aqueous solution lithium-ion battery

A lithium-ion battery and aqueous solution technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance of lithium-ion batteries in aqueous solution and cannot meet the standards for industrial applications, so as to save production costs and increase conductivity , the effect of inhibiting the hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-3

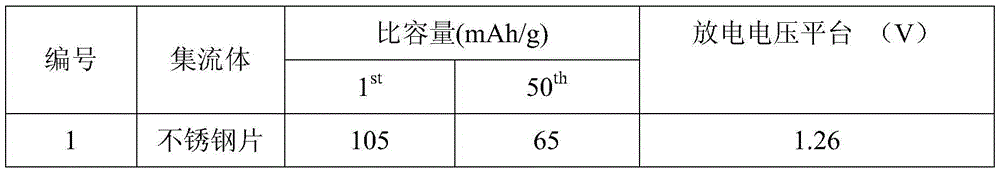

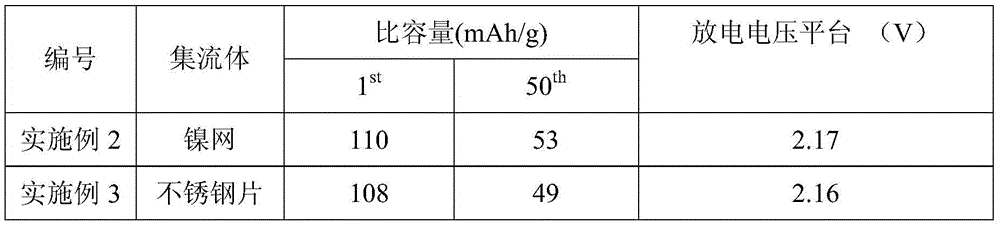

[0031] The process steps are: use lithium vanadium phosphate as the active material, PVDF as the binder, and conductive carbon black as the conductive agent, mix according to the mass ratio of active material: conductive agent: binder: 8:1:1, grind Uniformly and evenly press-coat on nickel mesh or stainless steel sheet, dry it in a drying oven at 120°C for 5 hours, use it as the positive and negative electrodes, smash it into the original sheet with a diameter of 14mm, and assemble it into a button battery, with the main component being 5molL -1 The lithium sulfate aqueous solution was used as the electrolyte, and the commercial PE-PP film was used as the separator, and its electrochemical cycle performance was tested at room temperature. The cycle performance at 0.5C rate is shown in Table 2.

[0032] Table 2. Experimental conditions and results of embodiment 2-3

[0033]

Embodiment 4-5

[0035]The process steps are: polyvinyl nitrile is used as binder, acetylene black is used as conductive agent, lithium vanadium phosphate is used as active material, and active material: conductive agent: binder is mixed according to the mass ratio of 7:2:1, and ground Evenly, press-coat on the lead-plated nickel sheet or stainless steel mesh collector fluid, dry it in a drying oven at 120 ° C for 5 hours, use it as the positive and negative electrodes, use 15wt.% lithium chloride solution as the electrolyte, and use PVDF-HFP co- The mixed membrane was used as a separator, and it was assembled into a button cell to test its electrochemical cycle performance. Its normal temperature cycle performance at 0.5C rate is shown in Table 3.

[0036] Table 3. Experimental conditions and results of embodiments 4-5

[0037]

Embodiment 6-10

[0039] The process steps are: use CMC / SBR as binder, conductive carbon black as conductive agent, and lithium vanadium phosphate as active material, mix according to the mass ratio of active material: conductive agent: binder: 90:5:5 , ground evenly, scrape-coated on a nickel mesh or stainless steel mesh collector, dried in a drying oven at 120°C for 5 hours, and plated a layer of indium with a thickness of 5-500nm on the surface of the electrode by magnetron sputtering (or electron beam evaporation). -Zinc alloy, using it as positive and negative electrodes, using saturated lithium nitrate solution (adding saturated lithium hydroxide to adjust pH = 8) as electrolyte, using commercial PE film as separator, assembled it into a battery and tested its electrochemical cycle at room temperature performance. Its cycle performance at 0.5C rate is shown in Table 4.

[0040] Table 4. Experimental conditions and results of embodiments 6-10

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com