Preparation method and applications of graphene sheet vertically oriented thin film material

A vertically oriented, thin-film material technology, applied in graphene, chemical instruments and methods, general water supply conservation, etc., can solve problems such as structural damage, and achieve low cost, simple preparation methods, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Prepare 7mg / mL graphene oxide solution by Hummers method;

[0051] 2. At a stirring rate of 3000r / min, add 100μL of ethanol to 3mL of graphene oxide solution, and continue stirring for 30min to obtain a uniformly mixed solution;

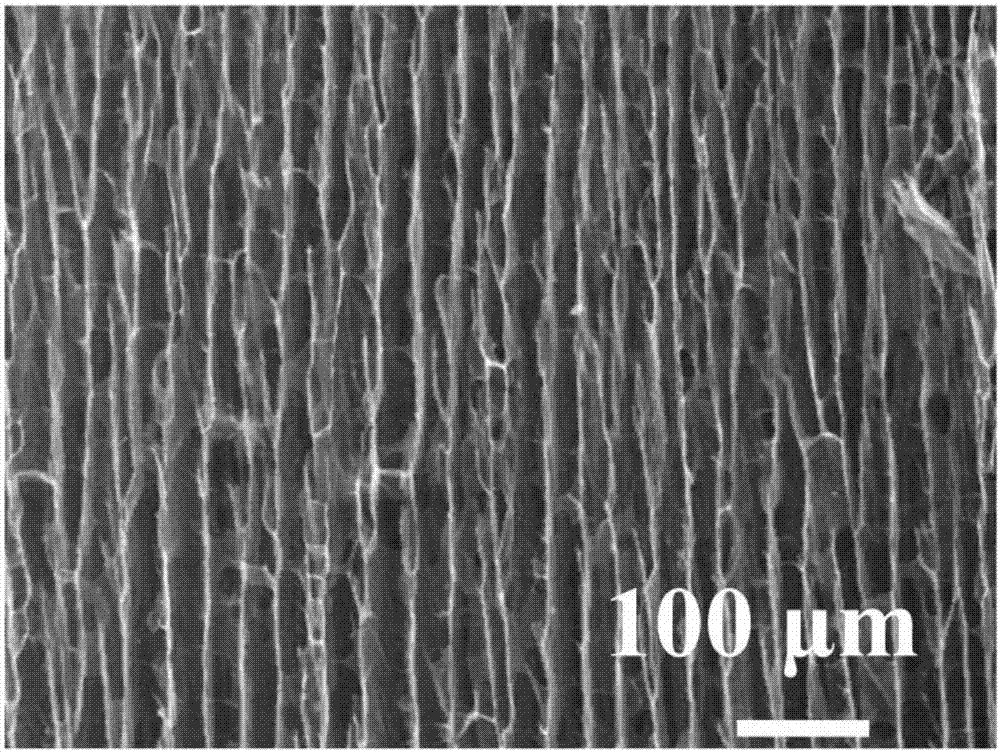

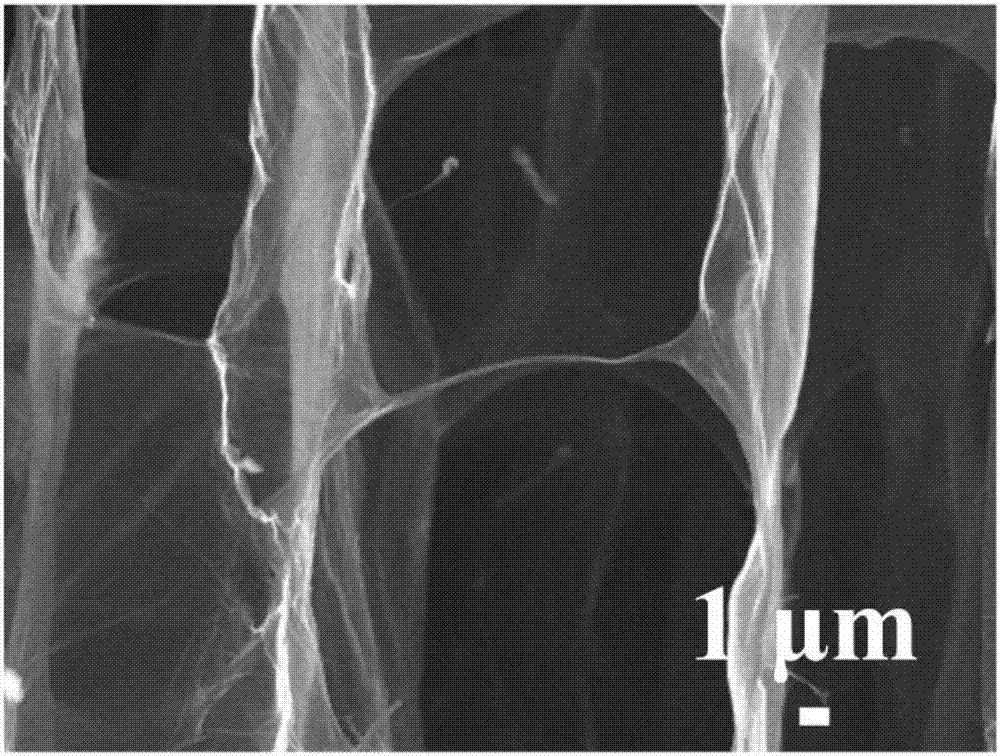

[0052] 3. Pour the uniformly mixed solution obtained in step 2 into a polytetrafluoroethylene container, and immediately place the bottom of the polytetrafluoroethylene container on the surface of liquid nitrogen for directional freezing from bottom to top to obtain graphene sheets vertically Hydrogels of oriented thin film materials;

[0053] 4. Freeze-dry the hydrogel of graphene sheet vertically oriented film material at -45°C for 72 hours to obtain the aerogel of graphene sheet vertically oriented film material;

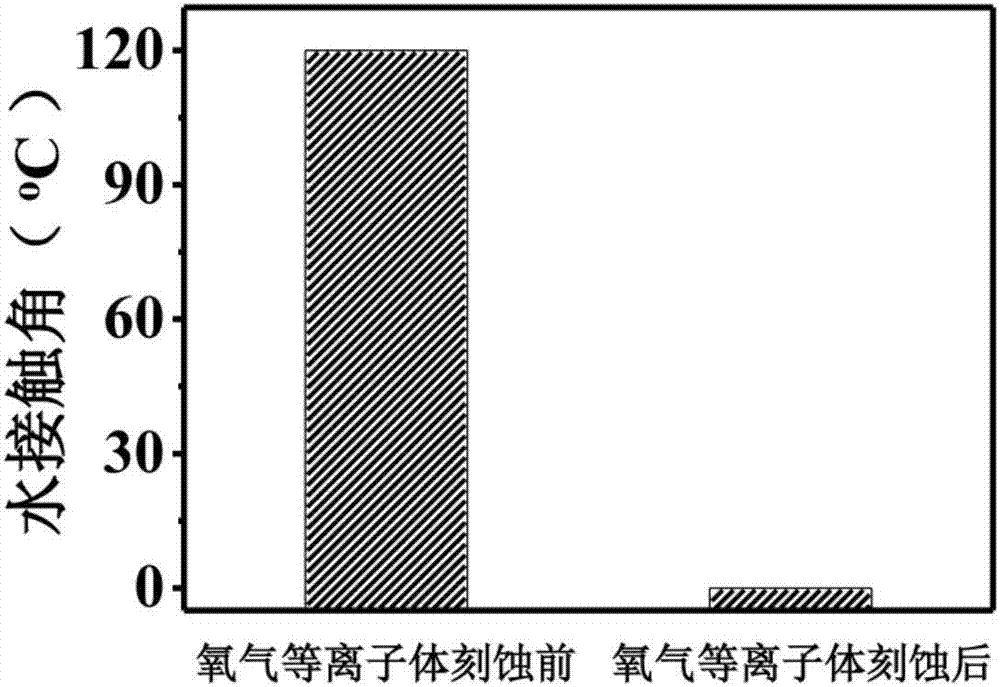

[0054] 5. Under the protection of an argon atmosphere, anneal the graphene vertically oriented film material aerogel at 150°C for 3 hours, and then anneal at 1000°C for 2 hours to obtain a reduced graphene sheet vertically or...

Embodiment 2

[0057] 1. Prepare 5mg / mL graphene oxide solution by Hummers method;

[0058] 2. At a stirring rate of 3000r / min, add 30μL of ethanol to 3mL of graphene oxide solution, and continue stirring for 30min to obtain a uniformly mixed solution;

[0059] 3. Pour the uniformly mixed solution obtained in step 2 into a polytetrafluoroethylene container, and immediately place the bottom of the polytetrafluoroethylene container on the surface of liquid nitrogen for directional freezing from bottom to top to obtain graphene sheets vertically Hydrogels of oriented thin film materials;

[0060] 4. Freeze-dry the hydrogel of graphene sheet vertically oriented film material at -50°C for 60 hours to obtain the aerogel of graphene sheet vertically oriented film material;

[0061] 5. Under the protection of an argon atmosphere, anneal the graphene vertically oriented film material aerogel at 200°C for 1 hour, and then anneal at 800°C for 3 hours to obtain a reduced graphene sheet vertically orien...

Embodiment 3

[0064] 1. Prepare 7mg / mL graphene oxide solution by Hummers method;

[0065] 2. At a stirring rate of 3000r / min, add 60μL methanol to 3mL graphene oxide solution, and continue stirring for 30min to obtain a uniformly mixed solution;

[0066] 3. Pour the uniformly mixed solution obtained in step 2 into a polytetrafluoroethylene container, and immediately place the bottom of the polytetrafluoroethylene container on the surface of liquid nitrogen for directional freezing from bottom to top to obtain graphene sheets vertically Hydrogels of oriented thin film materials;

[0067] 4. Freeze-dry the hydrogel of graphene sheet vertically oriented film material at -55°C for 48 hours to obtain the aerogel of graphene sheet vertically oriented film material;

[0068] 5. Under the protection of an argon atmosphere, anneal the graphene vertically oriented film material aerogel at 200°C for 2 hours, and then anneal at 600°C for 4 hours to obtain a reduced graphene sheet vertically oriented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com