High-density nitrogen doped graphene as well as preparation method and application thereof

A nitrogen-doped graphene, high-density technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult to overcome ion transport, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a first aspect, the present invention provides a method for preparing the aforementioned high-density nitrogen-doped graphene, the method comprising:

[0027] (1) In the presence of a solvent, a nitrogen source is contacted with graphene oxide;

[0028] (2) drying the product obtained through step (1);

[0029] (3) Reducing the product obtained after drying in step (2).

[0030] In the present invention, the graphene oxide is usually in the form of a solution, for example, a graphene oxide aqueous solution or a graphene oxide ethanol solution.

[0031] In the present invention, in step (1), the graphene oxide can be obtained commercially, or can be prepared by various methods known in the art. For example, chemical graphite oxide method (Hummers method), ultrasonic assisted Hummers method or FeCl 3 Oxidation method to prepare graphene oxide. In the preparation example of the present invention, the graphene oxide is prepared by the chemical graphite oxide method. ...

preparation example 1

[0061] Preparation Example 1 is used to prepare graphene oxide aqueous solution.

[0062] Examples 1-9 are used to prepare high-density nitrogen-doped graphene.

[0063] Preparation Example 1

[0064] Assemble a 250mL reaction bottle in an ice-water bath, add 80mL of concentrated sulfuric acid, add a solid mixture of 3g of graphite powder and 1.5g of sodium nitrate under stirring, then add 9g of potassium permanganate in batches, control the reaction temperature not exceeding 10°C, and stir 30min, then raise the temperature to about 35°C, continue to stir for 30min, then slowly add 150mL of deionized water, continue stirring for 20min, add an appropriate amount of hydrogen peroxide to reduce the residual oxidant, and turn the solution into bright yellow. Filtrate while hot, and wash with 5% by weight of HCl solution and deionized water until no sulfate is detected in the filtrate, put it into a dialysis bag for dialysis, and obtain a graphene oxide solution with a concentrati...

Embodiment 1

[0066] Add 1mL of 0.3% hydrogen peroxide and 0.1mL of pyrrole to 10mL of graphene oxide solution with a concentration of 4mg / mL, and transfer the mixed solution to a 25mL reactor, keep it at 180°C for 6h, then cool the reactor to room temperature Finally, the product was taken out; the product was washed with deionized water and then dried at 35°C for 48h; then the dried product was heated to 850°C in an argon atmosphere, kept at 850°C for 2h, and then cooled naturally to obtain a high Density nitrogen-doped graphene C1 (density 1.1912g / cm 3 ).

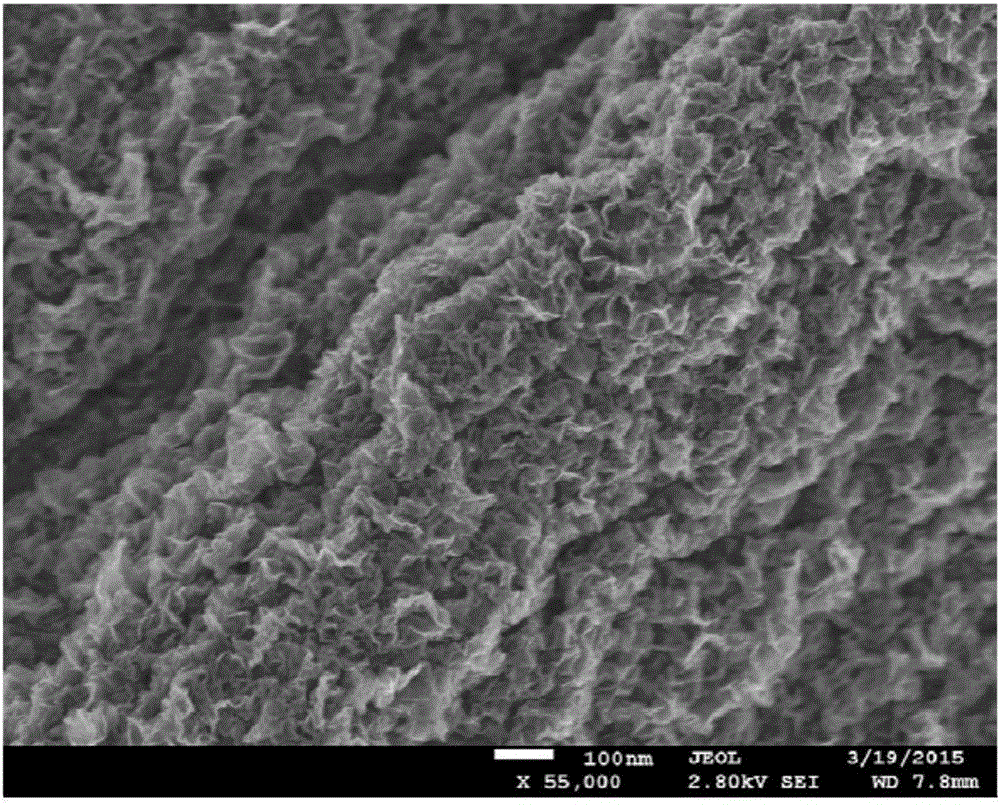

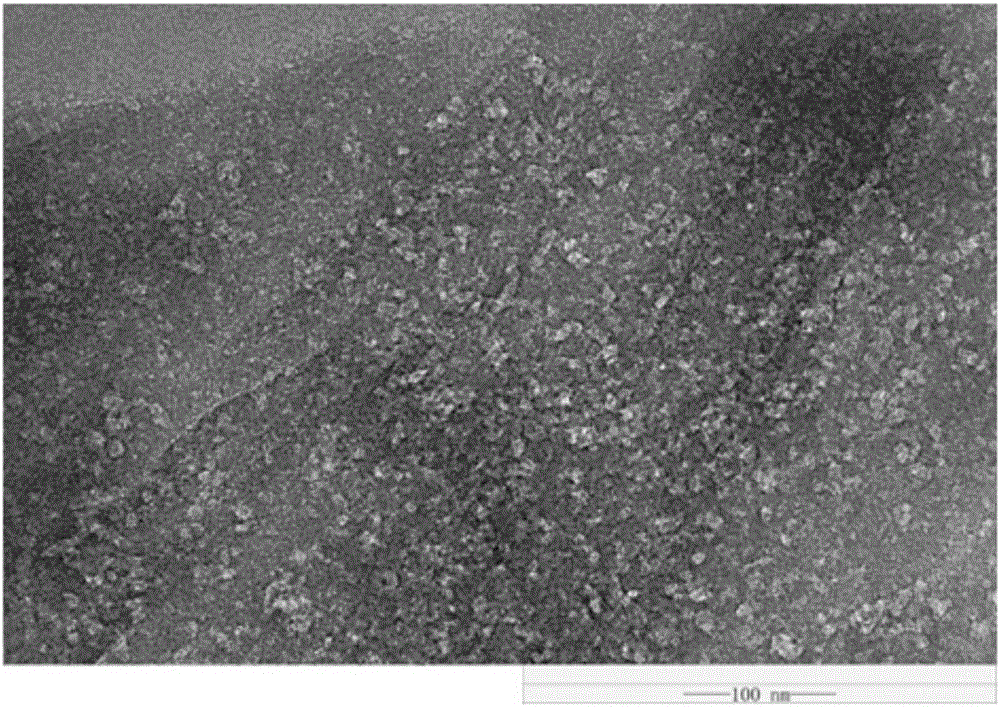

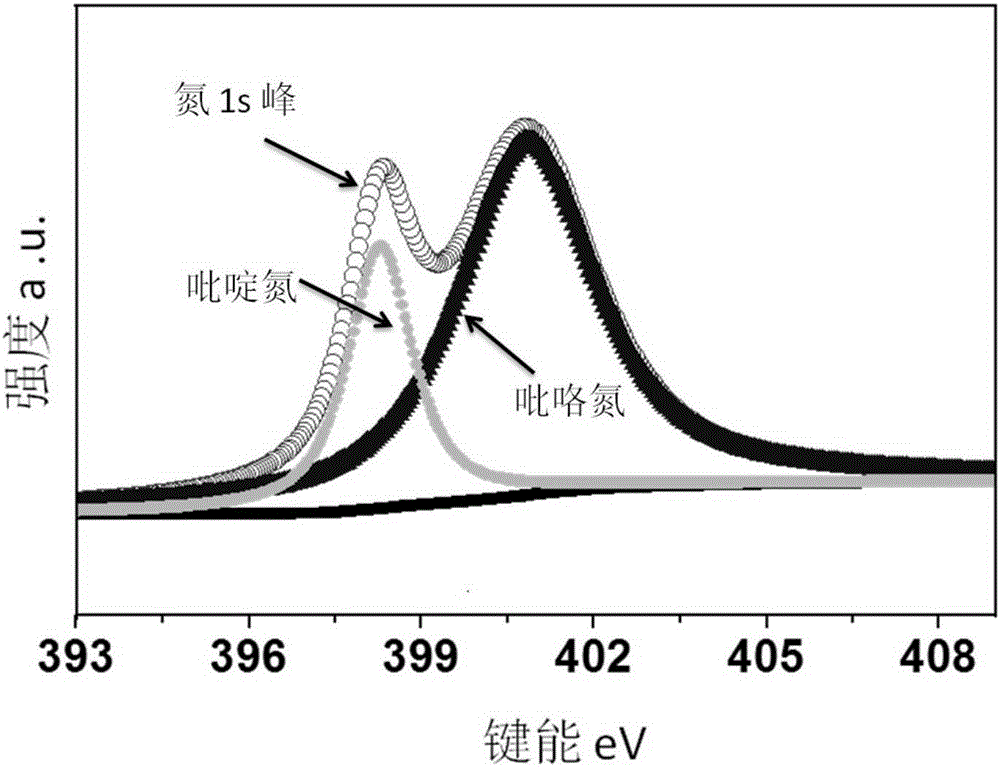

[0067] Detection of high-density nitrogen-doped graphene C1, through figure 1 The scanning electron microscope test results shown and figure 2 From the transmission electron microscope test results shown, it can be seen that the structure of high-density nitrogen-doped graphene C1 is a compact wrinkled porous graphene structure. Through the X-ray powder diffraction test, it is known that the high-density nitrogen-doped graphene C1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume specific capacity | aaaaa | aaaaa |

| Volume specific capacity | aaaaa | aaaaa |

| Volume specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com