Method for determining phosphorus in silicon-manganese alloy

A measurement method, silicon-manganese alloy technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc. It can solve the problems of unstable analysis results, poor stability, and long analysis time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 0.0600 g of No. 1 silicon-manganese alloy sample and place it in a 150 ml polytetrafluoroethylene beaker, add 10 ml of nitric acid, drop 5 ml of hydrofluoric acid to dissolve, add 5 ml of perchloric acid, heat and smoke to condense to 2 ml, and obtain the first mixture solution, the No. 1 silicon-manganese alloy sample is GSB03-1947-2005 standard sample, and the P content is 0.078wt%;

[0044] Remove the first mixed solution and cool it slightly, add 10ml of distilled water with a temperature of 60-70°C, rinse the beaker wall with distilled water, heat, add anhydrous sodium sulfite dropwise to reduce manganese, boil until the solution is clear, cool to room temperature, turn to into a 100ml volumetric flask, diluted to the mark, and shaken to obtain the second mixed solution;

[0045] Accurately pipette 10.00ml of the second mixed solution in a 50ml volumetric flask, add 5ml of bismuth nitrate solution configured by nitric acid solution, the nitric acid solution i...

Embodiment 2~4

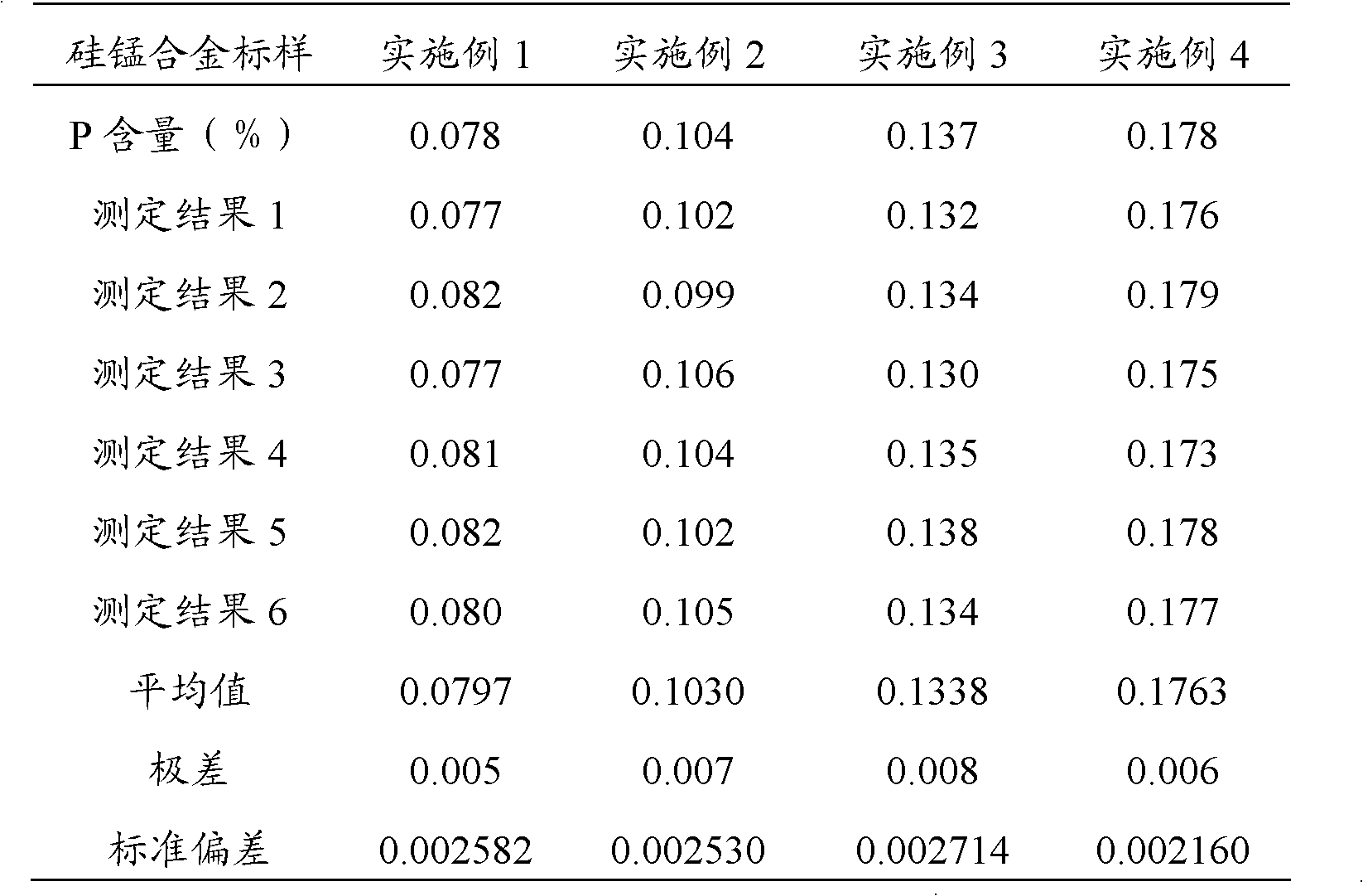

[0050] Get respectively No. 2 silicon-manganese alloy sample, No. 3 silicon-manganese alloy sample and No. 4 silicon-manganese alloy sample, adopt the method of embodiment 1 to carry out 6 parallel measurements to the phosphorus content in the silicon-manganese alloy, the results are shown in Table 1 shown. No. 1 silicon manganese alloy sample is GSB03-1947-2005 standard sample, P content is 0.078wt%; No. 2 silicon manganese alloy sample is GSB03-1359-2001 standard sample, P content is 0.104wt%; The silicon-manganese alloy sample is the standard sample No. 09-100, and the P content is 0.137wt%; the No. 4 silicon-manganese alloy sample is the standard sample YSBC37645-02, and the P content is 0.178wt%.

[0051] The phosphorus content in the silicon-manganese alloy that table 1 embodiment 1~4 measures

[0052]

[0053]

[0054] Analysis of the above results: According to the "Procedures for Ensuring the Quality of Test Results": Regularly use certified standard materials ...

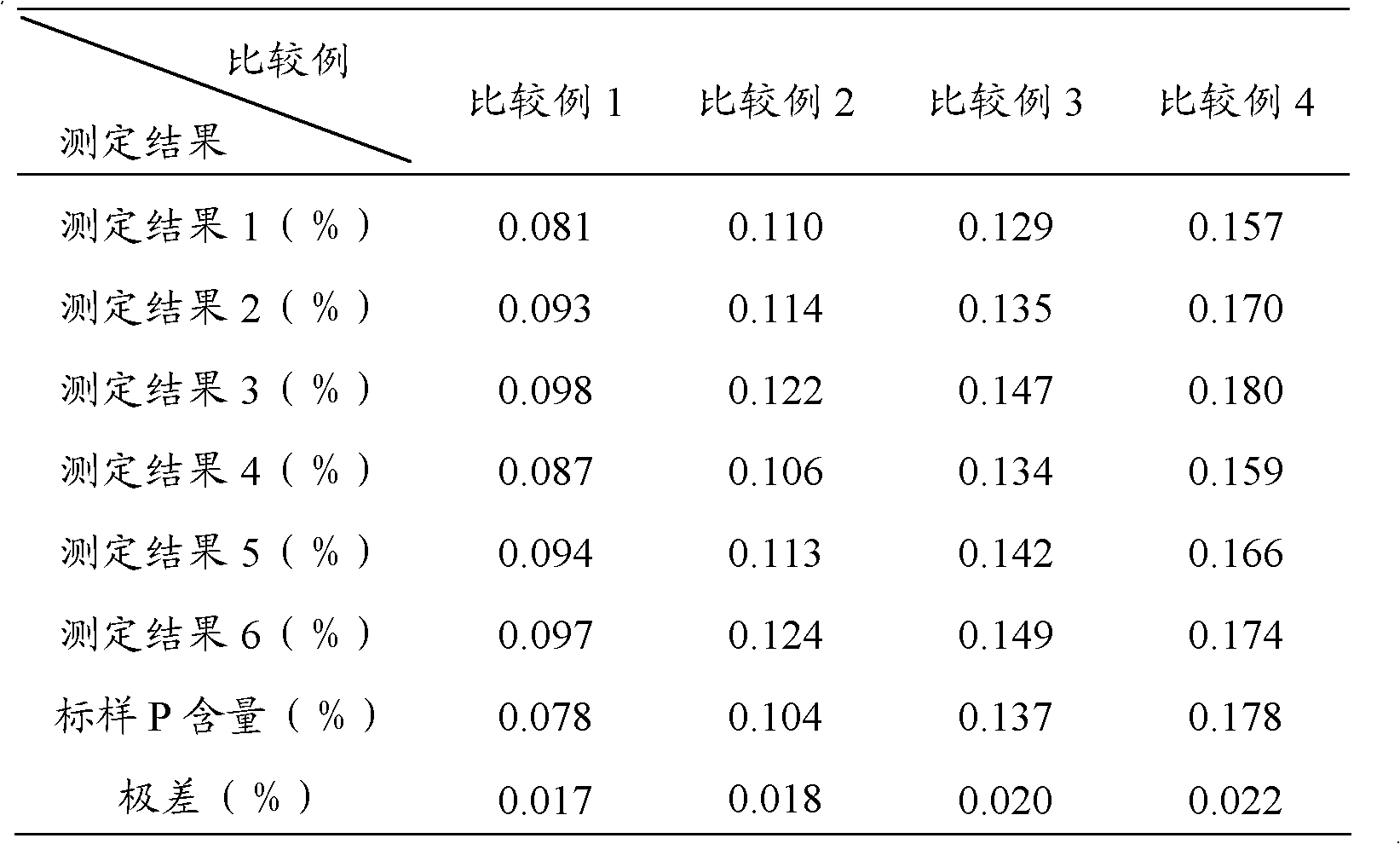

Embodiment 5~7

[0066] Get respectively No. 2 silicon-manganese alloy sample, No. 3 silicon-manganese alloy sample, No. 4 silicon-manganese alloy sample, adopt the method of embodiment 1 to measure the phosphorus content in each silicon-manganese alloy sample, each sample The measurements were performed twice, and the results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com