Method for preparing CuMn12Ni alloy by adopting vacuum induction melting

A vacuum induction melting and vacuum melting furnace technology, applied in the field of ferrous metal alloys, can solve problems such as patch resistivity, unqualified temperature coefficient of resistance, high impurity content of alloy materials, uneven composition and structure, etc. Uniform and consistent, reducing element burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

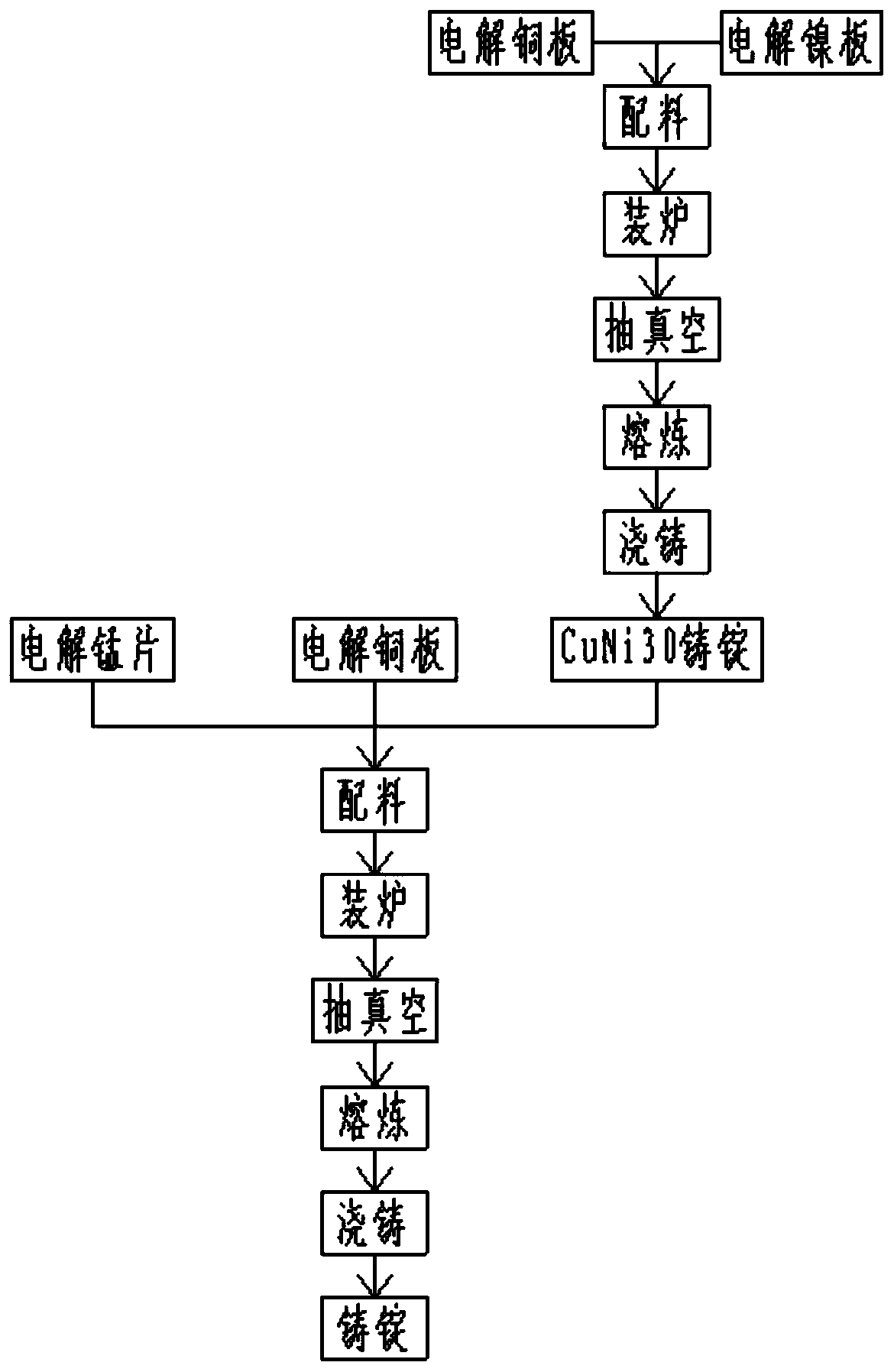

[0035] Embodiment 1: A kind of adopts vacuum induction melting to prepare CuMn 12 The method for Ni alloy, comprises the following steps:

[0036] 1) Ingredients: In terms of percentage content, the percentage content of each element in the raw material is: Mn 12%, Ni 2%, the balance is Cu, and the required raw materials are weighed in proportion; among them, Cu element is added in the form of electrolytic copper plate , the Mn element uses electrolytic manganese flakes, and the Ni element uses commercially available CuNi 3 0 master alloy;

[0037] 2) Furnace loading: Put the prepared alloy material into the crucible, close the furnace cover of the vacuum melting furnace, close the vent valve, and clean the observation window;

[0038] 3) Vacuuming: Turn on the mechanical pump, open the low-vacuum baffle valve to evacuate, and turn on the Roots pump when the vacuum pressure р in the vacuum melting furnace is 0.08MPa;

[0039] 4) Melting: When smelting, when the vacuum degre...

Embodiment 2

[0042] Embodiment 2: A kind of adopts vacuum induction melting to prepare CuMn 12 The method for Ni alloy, comprises the following steps:

[0043] 1) Ingredients: In terms of percentage content, the percentage content of each element in the raw material is: Mn 12.3%, Ni 2.05%, the balance is Cu, and the required raw materials are weighed in proportion; among them, Cu element is added in the form of electrolytic copper plate , Mn elements use electrolytic manganese flakes, and Ni elements use CuNi 3 0 master alloy, the CuNi 3 0 The preparation method of the master alloy is as follows: ① Ingredients: Calculated by percentage, the percentage content of each element in the raw material is: Cu 70%, Ni 30%, and the required raw materials are weighed in proportion; among them, the Cu element is in the form of electrolytic copper plate Adding, the Ni element is added in the form of electrolytic nickel plate; ② Furnace loading, put the prepared alloy material into the crucible, close...

Embodiment 3

[0049] Embodiment 3: A kind of adopts vacuum induction melting to prepare CuMn 12 The method for Ni alloy, comprises the following steps:

[0050] 1) Ingredients: In terms of percentage content, the percentage content of each element in the raw material is: Mn 12.3%, Ni 2.10%, the balance is Cu, and the required raw materials are weighed in proportion; among them, Cu element is added in the form of electrolytic copper plate , Mn elements use electrolytic manganese flakes, and Ni elements use CuNi 3 0 master alloy, the CuNi 3 0 The preparation method of the master alloy is as follows: ① Ingredients: Calculated by percentage, the percentage content of each element in the raw material is: Cu 70%, Ni 30%, and the required raw materials are weighed in proportion; among them, the Cu element is in the form of electrolytic copper plate Adding, the Ni element is added in the form of electrolytic nickel plate; ② Furnace loading, put the prepared alloy material into the crucible, close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com