Online detection and control system for flame combustion uniformity in sintering ignition furnace

A technology of flame combustion and control system, which is applied in the furnace control device, furnace, charge and other directions, and can solve the problem of not being able to adjust in a targeted manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

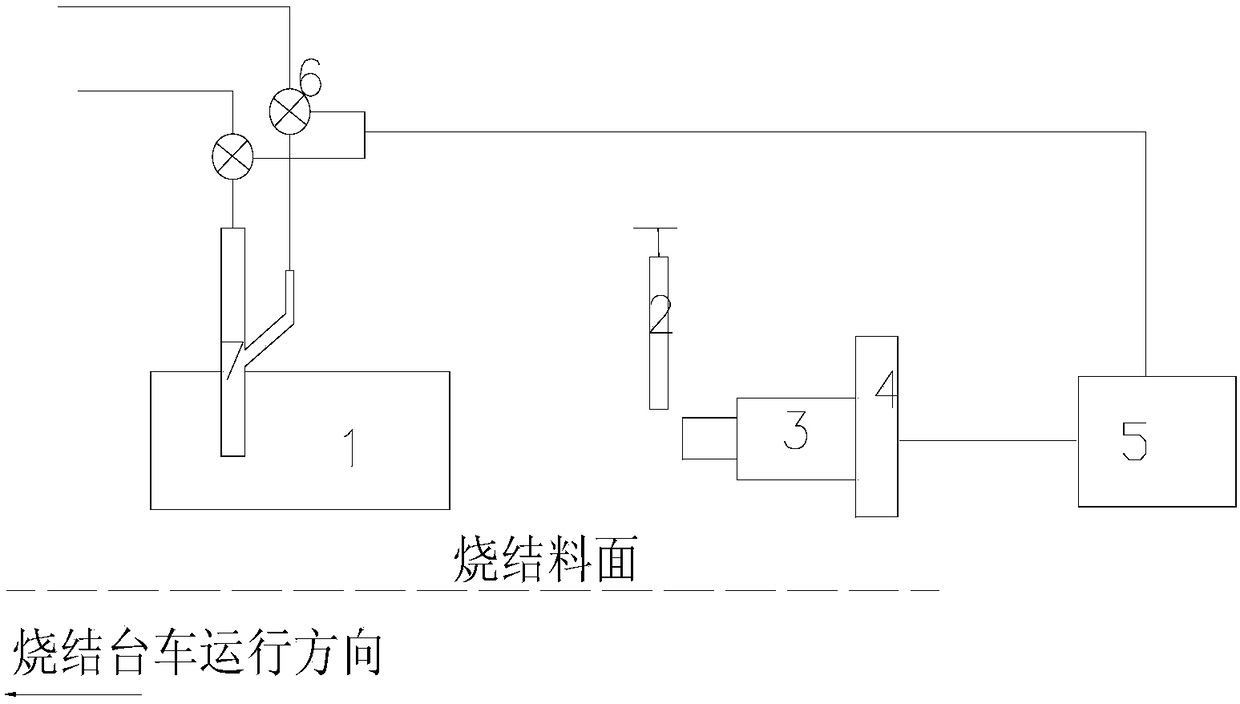

[0018] Such as figure 1 As shown, a detection and control system for the uniformity of flame combustion in the online sintering ignition furnace, the swing system 4 is arranged behind the sintering ignition furnace 1 and above the charge, and the high-temperature infrared thermal imager 3 is installed on the swing system 4. The nozzle 7 is evenly installed inside the sintering ignition furnace 1. The burner is connected to the air and gas pipelines through the electric regulating valve 6. The electric regulating valve 6 is connected to the industrial control machine 5 through the power line. The industrial control machine 5 is connected to the electric regulating valve. 6. Adjust the gas and air flow to adjust the specific temperature inside the ignition furnace.

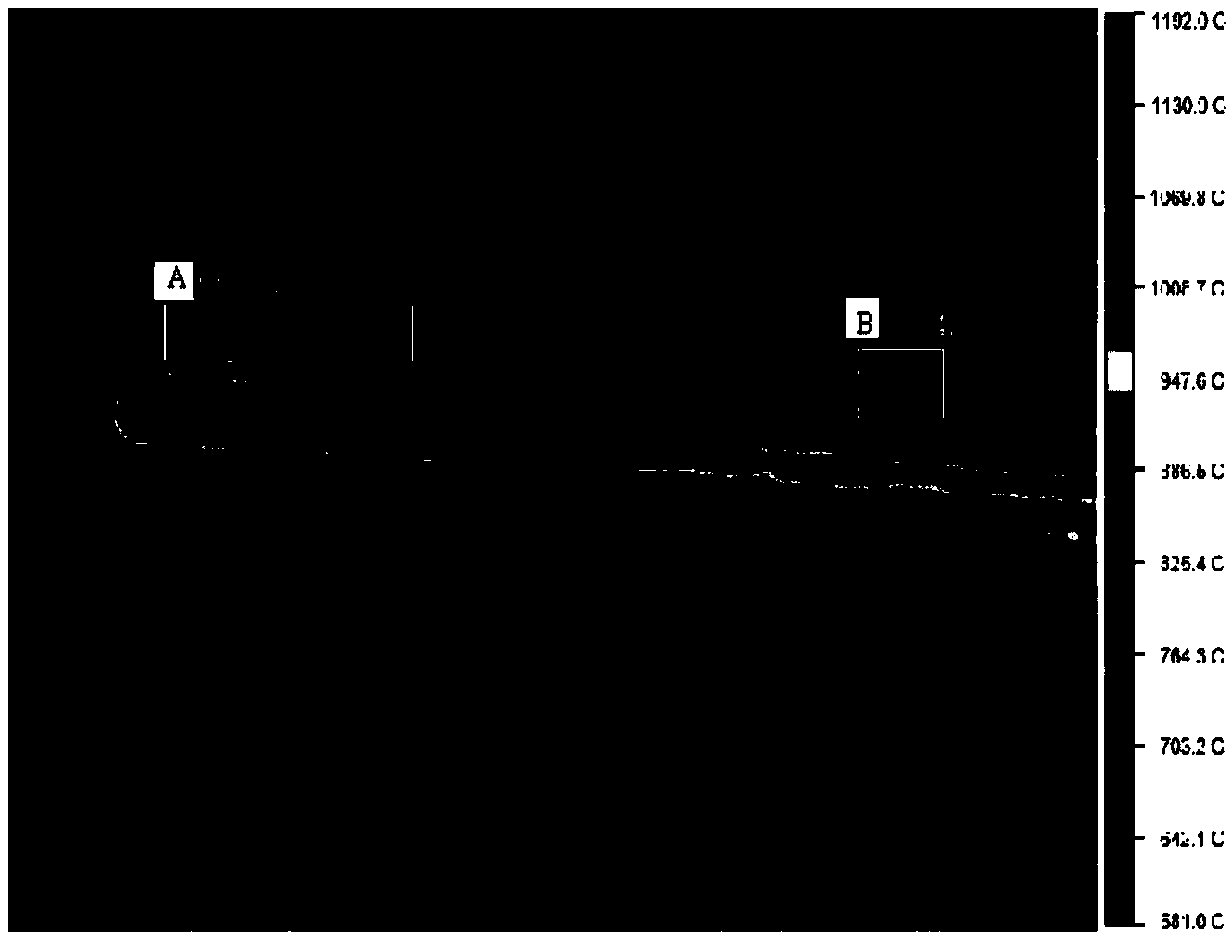

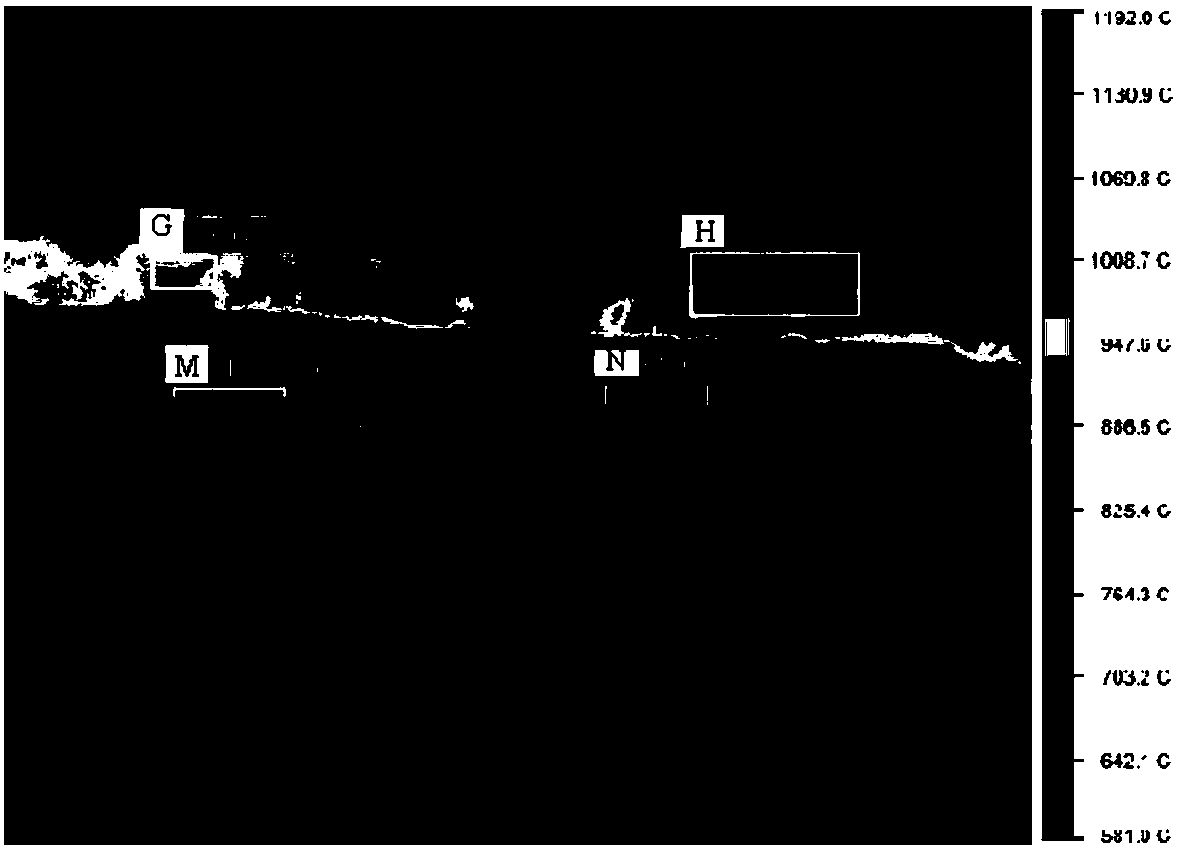

[0019] When the sintering trolley is running normally, the sintering ignition temperature T 设 =850°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com