Establishment method for sintering end point prediction system based on big data and machine learning

A technology of sintering end point and establishment method, which is applied in the direction of lighting and heating equipment, furnace type, furnace control device, etc., and can solve the problems of difficult calculation of vertical sintering speed, inability to predict accurately in practice, and few models for sintering end state prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

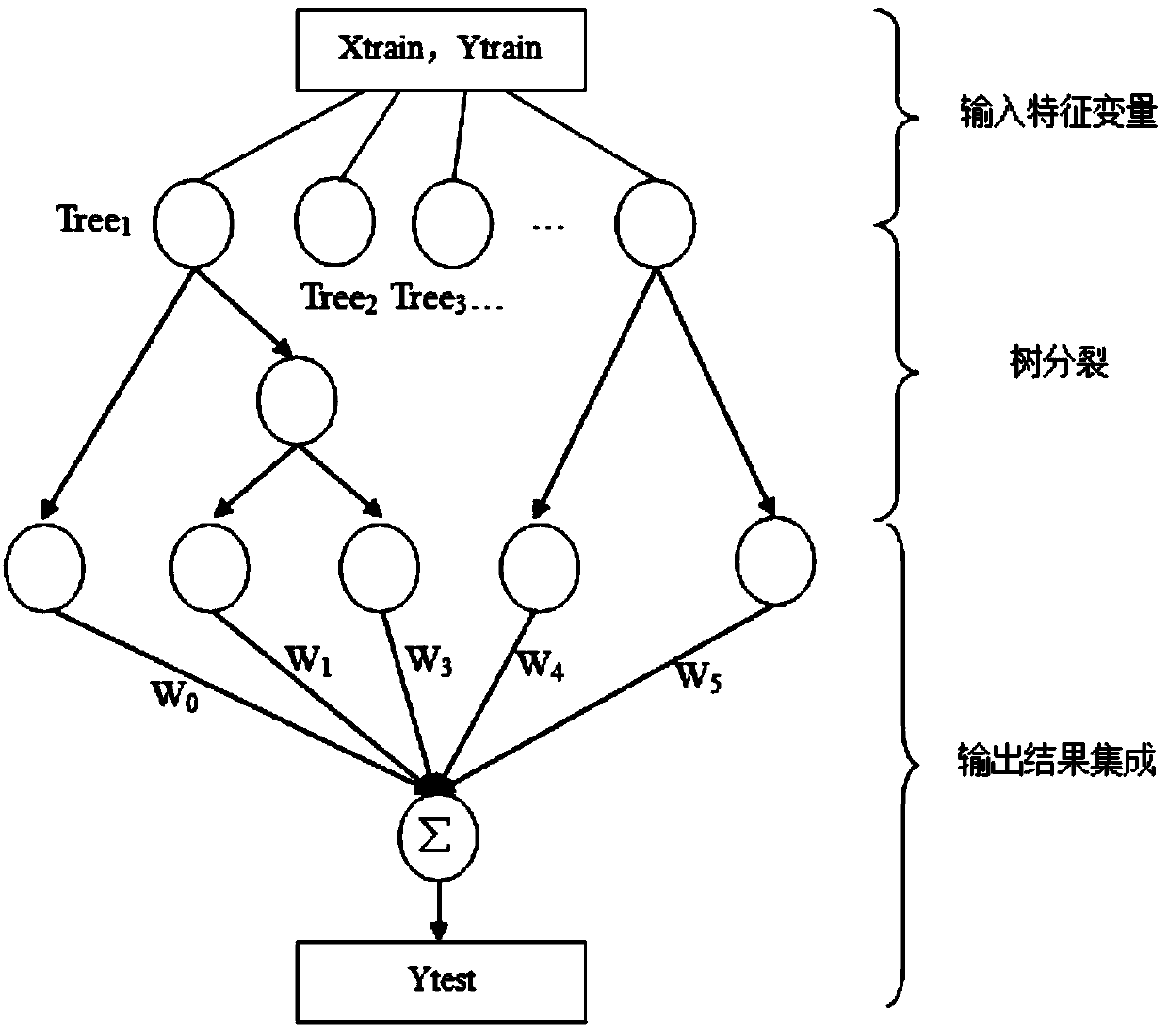

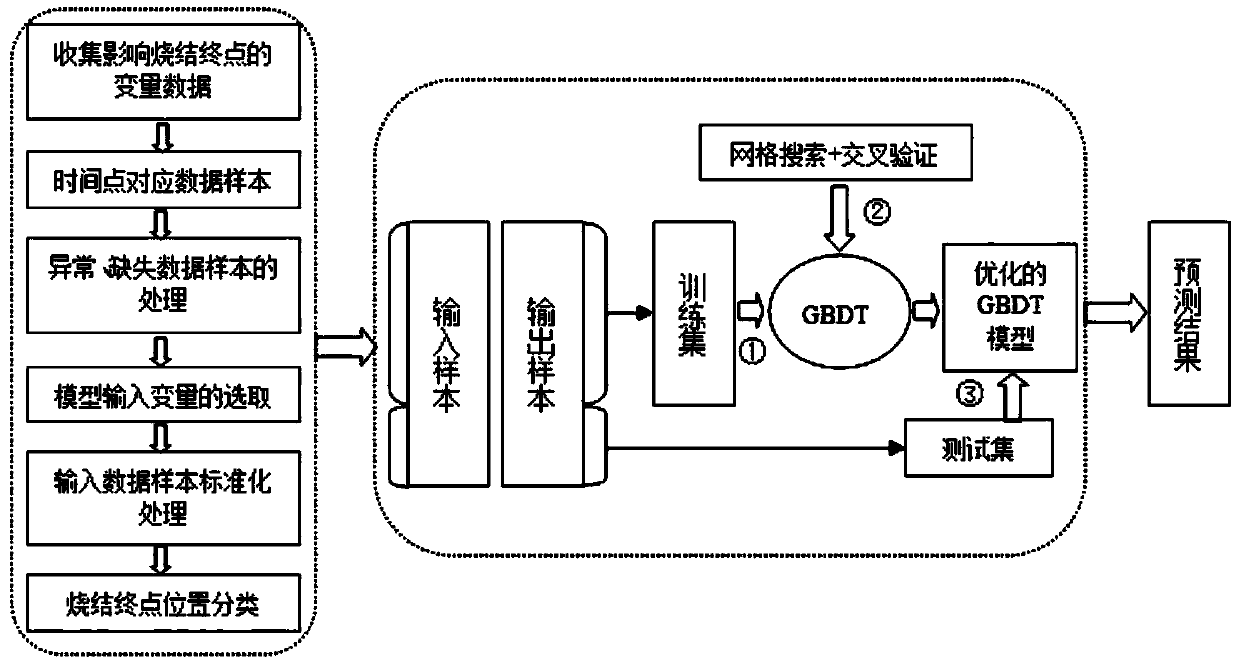

Method used

Image

Examples

Embodiment 1

[0107] Present embodiment 1 is in certain steel factory 360m 2 Sintering machine for experimental testing.

[0108] A method for establishing a sintering end point prediction model based on big data and machine learning, specifically comprising the following steps:

[0109] 1) Collect historical data. The sintering process control and data acquisition are realized through the configuration software of the automation system. The automation system includes production process data, equipment status data, inspection data and other components. The data from the sintering production process include: the moisture content of the mixture, the speed of the round roller, the speed of the nine rollers, the thickness of the material layer, the ignition temperature, the pressure of the combustion-supporting air, the flow of the combustion-supporting air, the gas pressure, the gas flow, and the speed of the sintering machine; Equipment status data includes: main pipeline negative pressure...

Embodiment 2

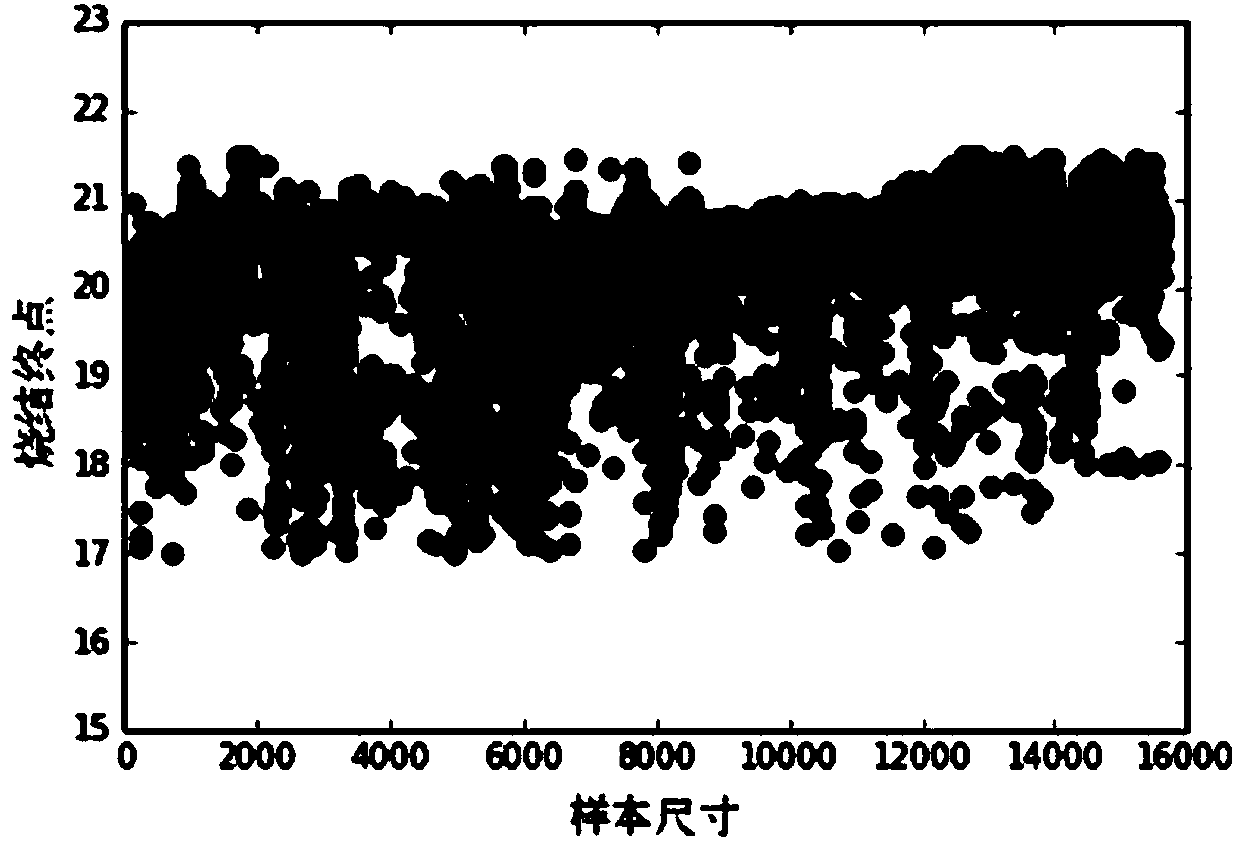

[0121] This embodiment 2 relates to a method of using the prediction model established in embodiment 1 to predict the classification trend of the sintering end position, specifically selecting a set of variable data as input variables and inputting them into the prediction model to obtain the sintering end position of the distribution. Specifically, a total of 1588 sets of data from 17:00 on December 30, 2014 to 16:00 on April 20, 2017 were selected for processing using the data processing method described in Example 1. Among them, 3117 groups of test samples randomly selected are input into the model, and the test samples distributed between 5000 and 6000 groups of total data samples are intercepted for display. Figure 4 It can be seen that most of the change trends fall within the interval of the normal sintering end point, but there are still some samples falling within the interval of the abnormal sintering end point, and the number of samples that deviates from the norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com