Preparation method of Cf/SiC composite material with HfB2 interface

A composite material, hfb2-sibnc technology, applied in the field of preparation of Cf/SiC composite materials, can solve problems such as prone to oxidation reactions, achieve the effects of shortening the preparation cycle, saving energy, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

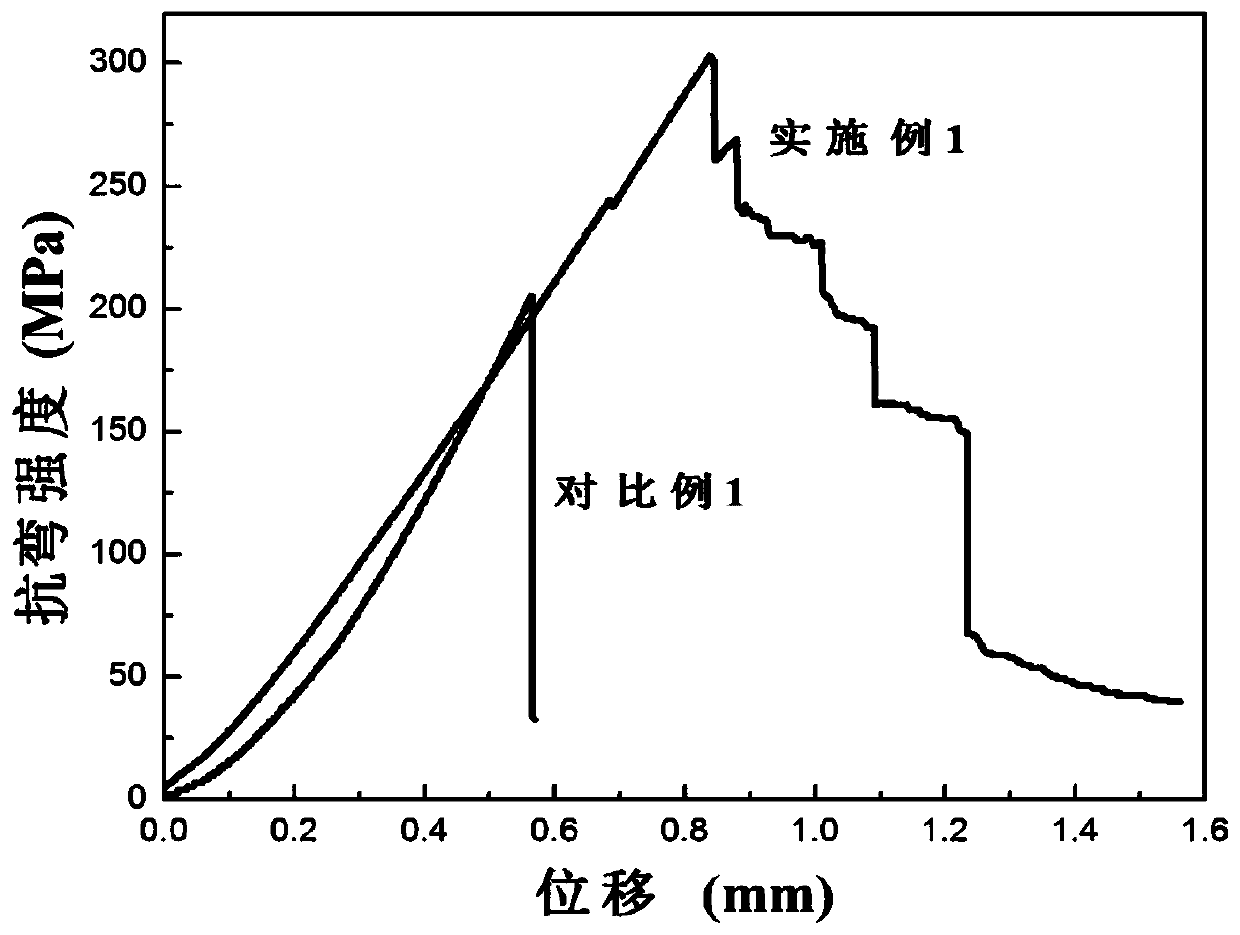

Embodiment 1

[0048] a HfB 2 The preparation method of the Cf / SiC composite material of interface, it comprises the following steps:

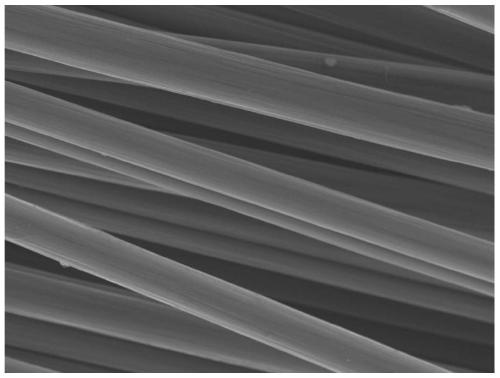

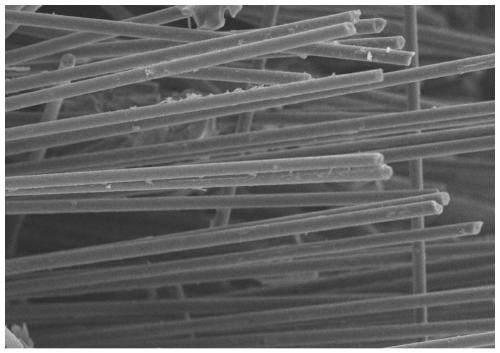

[0049] Put the carbon fiber in a tube furnace at 450°C for 30 minutes for degumming treatment, soak and etch the degummed carbon fiber in concentrated nitric acid for 60 minutes, then wash the residual liquid on the surface of the carbon fiber with deionized water, and dry it Obtain the carbon fiber after surface activation treatment; Ultrasonic impregnation of the above-mentioned dried carbon fiber preform in HfB 2Precursor solution with a low concentration of the interface phase for 30 minutes, the coated carbon fibers were left at room temperature for 12 hours, then placed in an oven at 60 ° C for 60 minutes, and then placed in a tube furnace, under the protection of nitrogen. Heat at a heating rate of 3°C / min to 300°C for 10 minutes, then heat at a heating rate of 5°C / min to 550°C, hold for 40 minutes, then heat at a heating rate of 8°C / min to 800°C, an...

Embodiment 2

[0054] a HfB 2 The preparation method of the Cf / SiC composite material of interface, it comprises the following steps:

[0055] Put the carbon fiber in a tube furnace at 450°C for 40 minutes for degumming treatment, soak and etch the degummed carbon fiber in concentrated nitric acid for 60 minutes, then wash the residual liquid on the surface of the carbon fiber with deionized water, and dry it Obtain the carbon fiber after surface activation treatment; Ultrasonic impregnation of the above-mentioned dried carbon fiber preform in HfB 2 Precursor solution with a low concentration of the interface phase for 40 minutes, the coated carbon fiber was left at room temperature for 15 hours, then placed in an oven at 60°C for 60 minutes, and then placed in a tube furnace, under the protection of nitrogen. Heat at a heating rate of 3°C / min to 300°C for 10 minutes, then heat at a heating rate of 5°C / min to 550°C, hold for 40 minutes, then heat at a heating rate of 9°C / min to 800°C, and h...

Embodiment 3

[0057] a HfB 2 The preparation method of the Cf / SiC composite material of interface, it comprises the following steps:

[0058] Put the carbon fiber in a tube furnace at 450°C for 30 minutes for degumming treatment, soak and etch the degummed carbon fiber in concentrated nitric acid for 100 minutes, then wash the residual liquid on the surface of the carbon fiber with deionized water, and dry it Obtain the carbon fiber after surface activation treatment; Ultrasonic impregnation of the above-mentioned dried carbon fiber preform in HfB 2 Precursor solution with a low concentration of the interface phase for 10 minutes, the coated carbon fiber was left at room temperature for 12 hours, then placed in an oven at 60 ° C for 60 minutes, and then placed in a tube furnace, under the protection of nitrogen. Heat at a heating rate of 3°C / min to 300°C and hold for 15 minutes, then heat at a heating rate of 5°C / min to 550°C, hold for 40 minutes, then heat at a heating rate of 10°C / min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com