Preparation method of MOFs-based colorful electrochromic intelligent display device

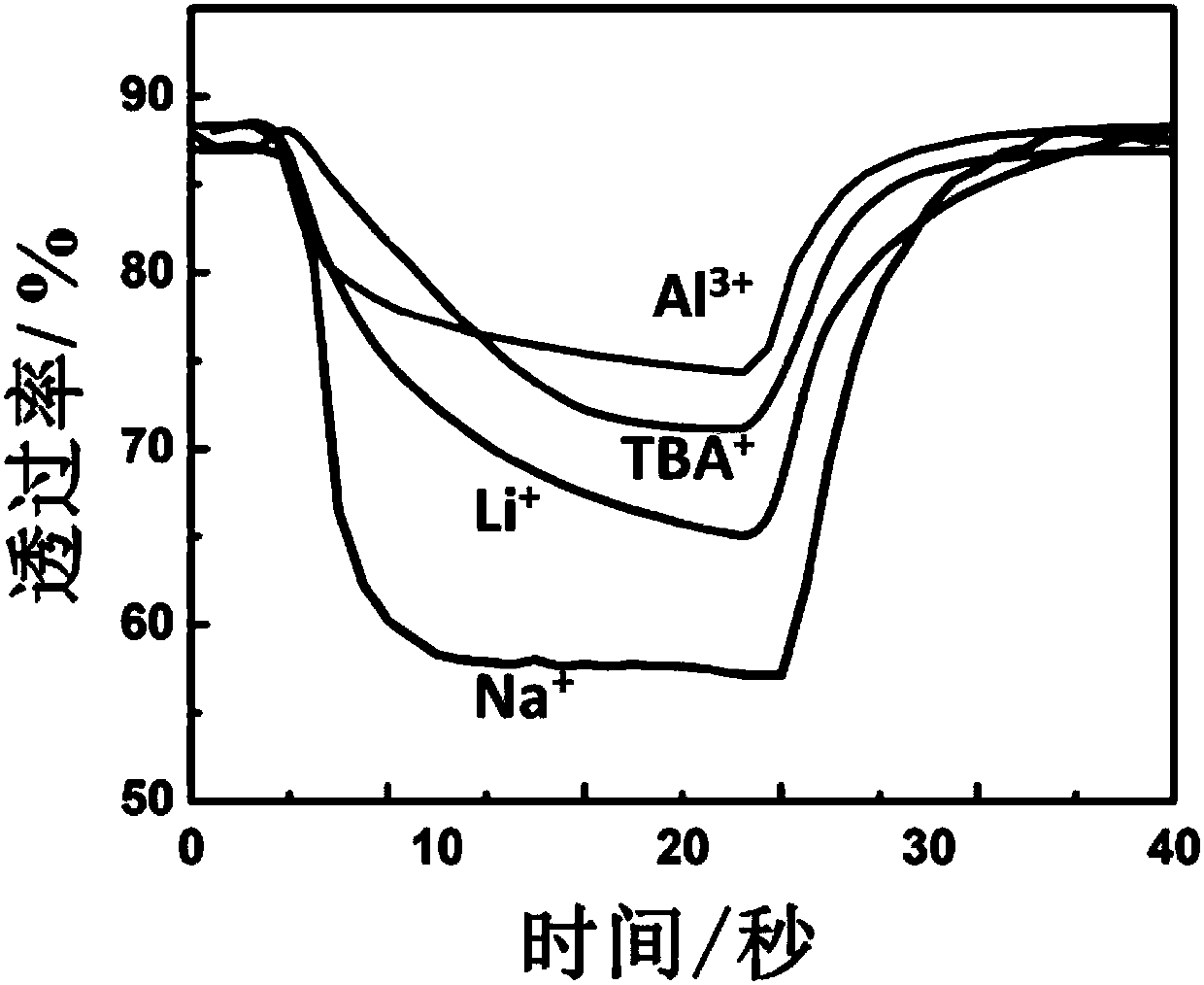

An intelligent display and color-changing technology, applied in chemical instruments and methods, color-changing fluorescent materials, instruments, etc., can solve the problems of non-compliance with high integration, intelligence, and single color change of inorganic materials, and achieve good ion storage capacity and Effects of electrochemical performance, low production cost, and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

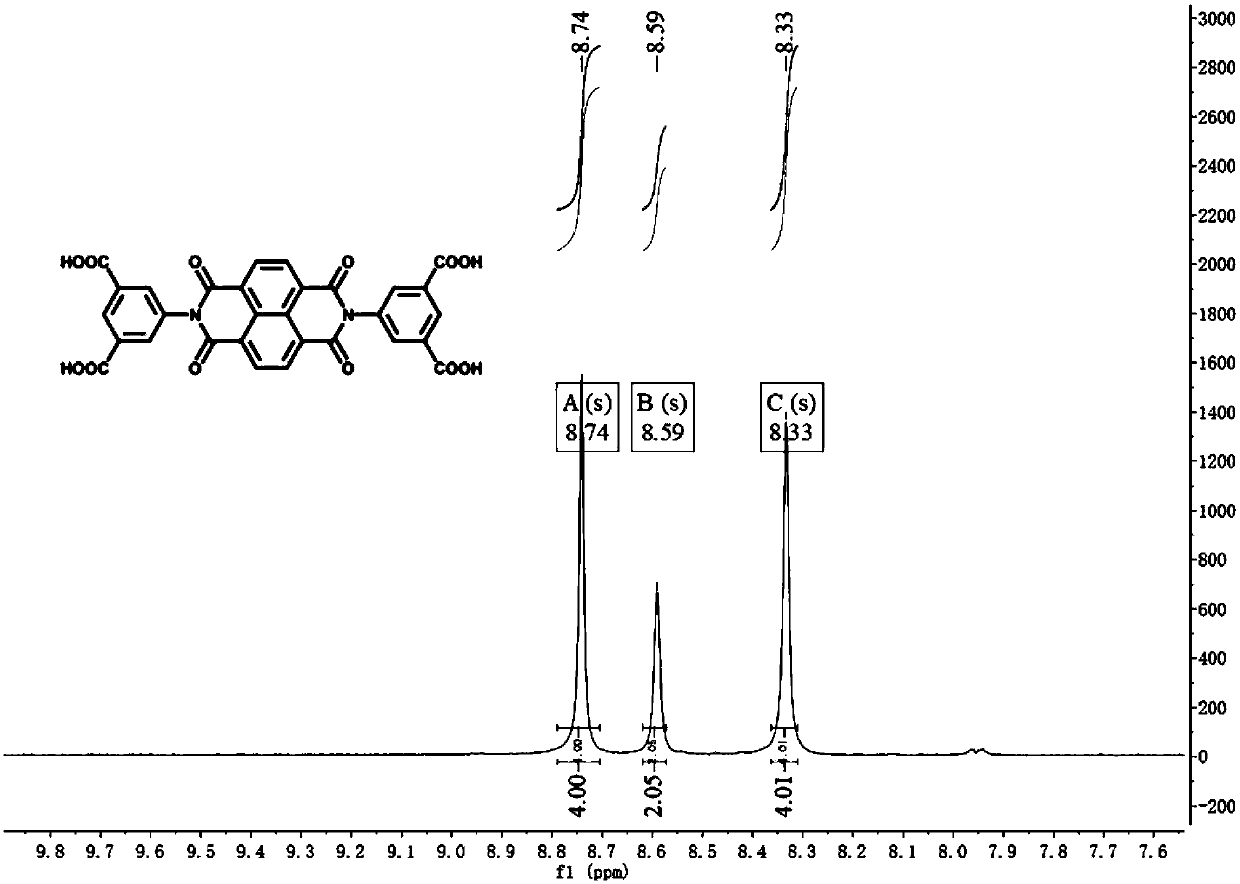

[0036] (1) Under the protection of nitrogen atmosphere, 1.5mmol of 1,4,5,8-naphthalene tetracarboxylic anhydride and 3.4mmol of 5-aminoisophthalic acid were dissolved in 50mL of toluene and refluxed at 150°C for 8h, filtered and dried. Recrystallization from DMF gave the naphthalene tetracarboxylic anhydride-based ligand as a pale yellow solid.

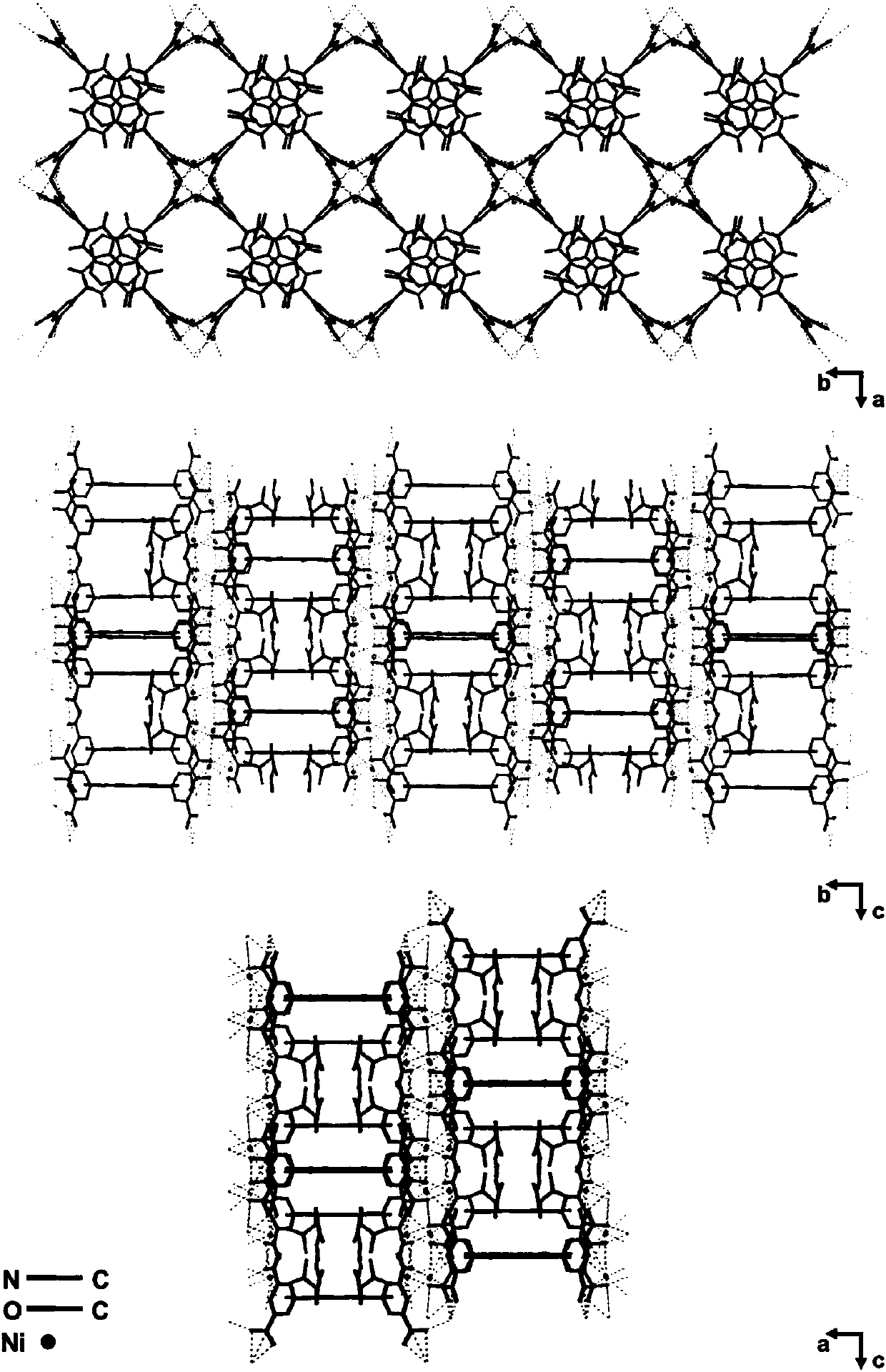

[0037] (2) 0.6 mmol of naphthalene tetracarboxylic anhydride-based ligands obtained in step (1) and 1 mmol of nickel nitrate hexahydrate are dissolved in a mixed solvent of 20 mL of DMF and 4 mL of water to obtain a mixed solution; the FTO glass is pretreated, and then immersed in deionized Water, acetone, and ethanol were each ultrasonically washed for 20 minutes, and dried; the mixed solution was poured into the inner tank of a water-heated kettle with a volume of 50 mL of water, and the pre-treated FTO glass was vertically inserted, and the water-heating reaction was carried out at 90°C for 1 hour, and then placed in DMF soaked in ...

Embodiment 2

[0043] (1) Under the protection of nitrogen atmosphere, dissolve 8 mmol of 1,4,5,8-naphthalene tetracarboxylic anhydride and 4 mmol of 5-aminoisophthalic acid in 150 mL of toluene at 120°C for 14 hours, filter, dry, and put in DMF Recrystallization gave a light yellow solid naphthalene tetracarboxylic anhydride-based ligand.

[0044] (2) 1 mmol of naphthalene tetracarboxylic anhydride-based ligand obtained in step (1) and 0.8 mmol of nickel nitrate hexahydrate are dissolved in a mixed solvent of 22 mL of DMF and 3 mL of water to obtain a mixed solution; the FTO glass is pretreated, and then immersed in deionized Ultrasonic washing in water, acetone and ethanol for 20 minutes respectively, and drying; pour the mixed solution into the inner tank of a hydrothermal kettle with a volume of 50mL of water, insert the pretreated FTO glass vertically, and conduct a hydrothermal reaction at 90°C for 0.5h, and then put it into Soak in DMF and methanol for 2 days each, and dry in vacuum a...

Embodiment 3

[0049] (1) Under the protection of nitrogen atmosphere, dissolve 1mmol of 1,4,5,8-naphthalene tetracarboxylic anhydride and 3mmol of 5-aminoisophthalic acid in 60mL of toluene at 100°C for 10h at reflux, filter, dry, and place in DMF Recrystallization gave a light yellow solid naphthalene tetracarboxylic anhydride-based ligand.

[0050] (2) 0.5 mmol of naphthalene tetracarboxylic anhydride-based ligands obtained in step (1) and 0.8 mmol of nickel nitrate hexahydrate are dissolved in a mixed solvent of 20 mL of DMF and 1.5 mL of water to obtain a mixed solution; the FTO glass is pretreated, followed by Soak in deionized water, acetone, and ethanol for 20 minutes, then dry; pour the mixed solution into a 50-mL water-heated kettle liner, insert the pretreated FTO glass vertically, and conduct a hydrothermal reaction at 120°C for 4 hours. Soak in DMF and methanol for 3 days respectively, and dry in vacuum at 60°C for 18 hours to obtain an FTO electrode with a metal-organic framewo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com