Water electrolysis efficient and double-function catalysis electrode and preparation method thereof

A dual-function catalysis, water electrolysis technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficulty in large-scale popularization, limited metal material reserves, general performance, etc., and achieves long service life, low cost, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

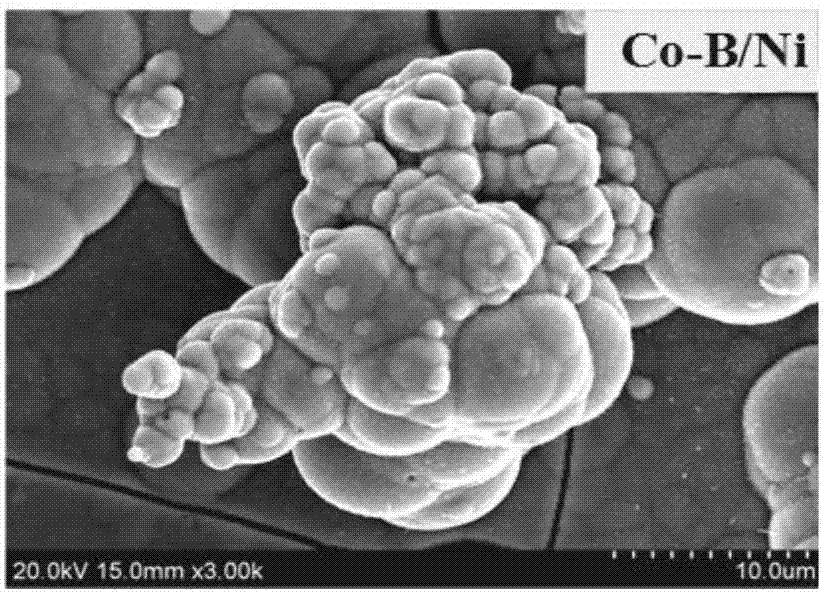

[0026] Embodiment 1, the preparation of Co-B / Ni electrode catalytic material

[0027] (1) Nickel substrate pretreatment

[0028] Place the nickel sheet in an acetone solution for ultrasonic cleaning for 30 minutes to remove the grease on the surface of the substrate, then place it in a nitric acid solution with a molar concentration of 3 mol / L, soak for 15 minutes to remove the oxide on the surface of the nickel substrate, and finally use a deionized Rinse with water, let it dry naturally;

[0029] (2) Configure an electroless plating solution containing Co-B, the ratio of each substance and the experimental conditions are shown in the following table:

[0030]

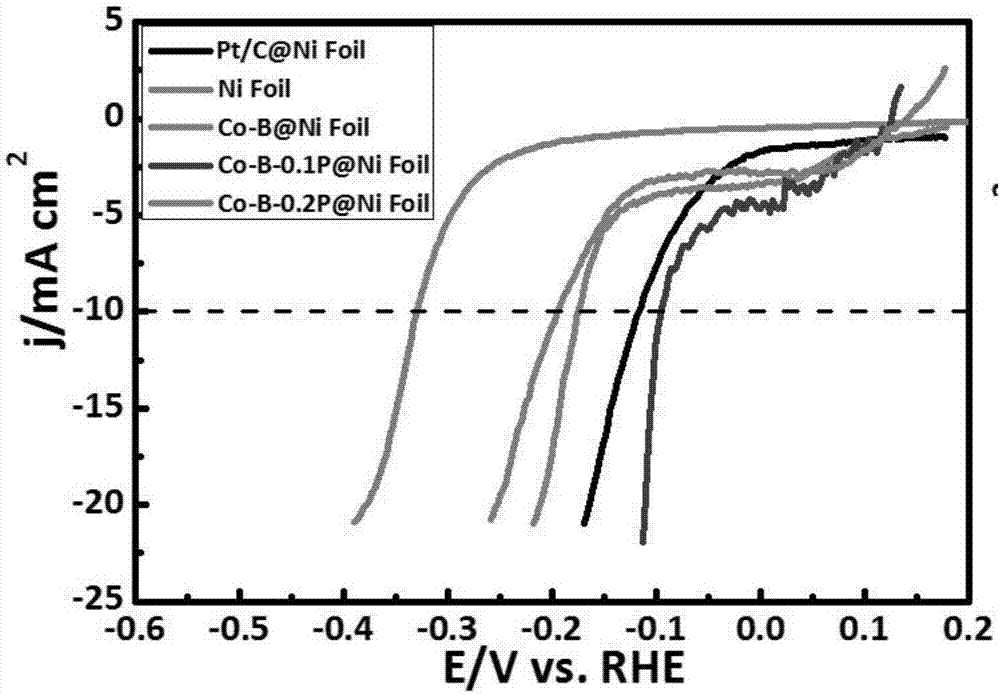

[0031] The pretreated nickel substrate is immersed in the above solution, and chemically deposited at 30° C. for 15 minutes to 12 hours; catalytic electrode materials with different deposition thicknesses can be obtained, rinsed with deionized water, and dried to obtain an electrode. Electrode photos and SEM imag...

Embodiment 2

[0034] Embodiment 2, the preparation of Co-B-P / Ni electrode catalytic material

[0035] (1) Nickel substrate pretreatment

[0036]Place the nickel sheet in an acetone solution for ultrasonic cleaning for 30 minutes to remove the grease on the surface of the substrate, then place it in a nitric acid solution with a molar concentration of 3mol / L, soak for 5 minutes, remove the oxides on the surface of the nickel substrate, and finally wash it with deionized water Rinse and let it dry naturally;

[0037] (2) Configure an electroless plating solution containing Co-B-P, the ratio of each substance and the experimental conditions are shown in the following table:

[0038]

[0039] The pretreated nickel substrate is immersed in the above solution, and chemically deposited at 30° C. for 15 minutes to 12 hours; catalytic electrode materials with different deposition thicknesses can be obtained, rinsed with deionized water, and dried to obtain an electrode. Electrode photos and SEM...

Embodiment 3

[0042] Embodiment 3, Ni-B / Ti electrode preparation

[0043] (1) Titanium substrate pretreatment

[0044] Place the titanium substrate in an acetone solution for ultrasonic cleaning for 10 minutes to remove the grease on the surface of the substrate, then place it in a nitric acid solution with a molar concentration of 3mol / L, soak for 15 minutes to remove the oxides on the surface of the titanium substrate, and finally use deionized Rinse with water, let it dry naturally;

[0045] (2) Configure the electroless plating solution containing Ni-B, the ratio of each substance and the experimental conditions are shown in the following table:

[0046]

[0047] The pretreated titanium substrate is immersed in the above solution, and chemically deposited at 30° C. for 15 minutes to 12 hours; catalytic electrode materials with different deposition thicknesses can be obtained, rinsed with deionized water, and dried to obtain an electrode. Electrode photo as Figure 7 shown;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com