Method for preparing nano-structure of metal chromite series compound

A technology of metal chromite and nanostructure, which is applied in the direction of chromium compounds, chemical instruments and methods, nanotechnology, etc., to achieve the effects of convenient operation, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

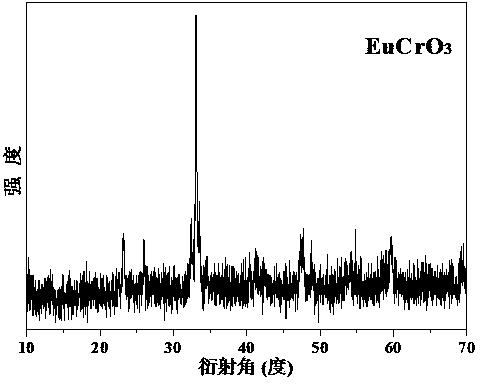

[0021] Embodiment 1: Europium chromite (EuCrO 3 ) preparation.

[0022] 1) Weigh 2mmol potassium chromate and 1mmol europium nitrate, and dissolve them in 20mL ethylene glycol and water mixed solvent (5mL ethylene glycol + 15mL distilled water, that is, the volume ratio of ethylene glycol to water is 1:3 ), under magnetic stirring, the potassium chromate solution was gradually added dropwise to the europium nitrate solution to form a suspension.

[0023] 2) Transfer the obtained suspension to a 50mL reaction autoclave, seal it, and react at a constant temperature of 150°C for 12-24 hours, and naturally cool to room temperature after the reaction.

[0024] 3) The hydrothermal reaction product is subjected to suction filtration, washed alternately with water and ethanol several times, and dried at 50° C. for 6 hours to obtain europium chromite powder product.

Embodiment 2

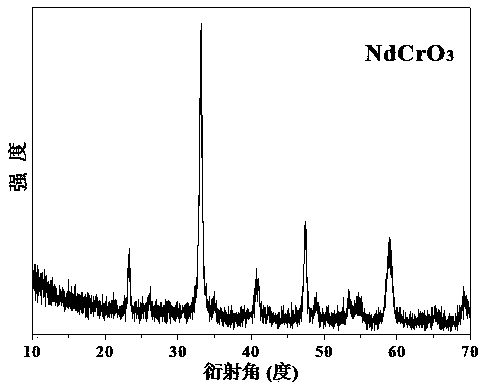

[0025] Embodiment 2: neodymium chromite (NdCrO 3 ) preparation.

[0026] 1) Weigh 2mmol potassium chromate and 1mmol neodymium nitrate, and dissolve them in 20mL ethylene glycol and water mixed solvent (5mL ethylene glycol + 15mL distilled water, that is, the volume ratio of ethylene glycol to water is 1:3 ), under magnetic stirring, the potassium chromate solution was gradually added dropwise to the neodymium nitrate solution to form a suspension.

[0027] 2) Transfer the obtained suspension to a 50mL reaction autoclave, seal it, and react at a constant temperature of 150°C for 12-24 hours, and naturally cool to room temperature after the reaction.

[0028] 3) The hydrothermal reaction product is subjected to suction filtration, washed alternately with water and ethanol several times, and dried at 50° C. for 6 hours to obtain a neodymium chromite powder product.

Embodiment 3

[0029] Embodiment 3: cobalt chromite (CoCr 2 o 4 ) preparation.

[0030] 1) Weigh 2mmol potassium chromate and 2mmol cobalt chloride, and dissolve them in 20mL ethylene glycol and water mixed solvent (10mL ethylene glycol + 10mL distilled water, that is, the volume ratio of ethylene glycol to water is 1: 1), under magnetic stirring, gradually add the potassium chromate solution to the cobalt chloride solution dropwise to form a suspension.

[0031] 2) Transfer the obtained suspension to a 50mL reaction autoclave, seal it, and react at a constant temperature of 150°C for 6-12 hours, and naturally cool to room temperature after the reaction.

[0032] 3) The hydrothermal reaction product is subjected to suction filtration, washed alternately with water and ethanol several times, and dried at 50° C. for 6 hours to obtain a cobalt chromite powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com