Anti-stripping agent for improving asphalt and stone adhesiveness and preparation method thereof

An anti-stripping agent and adhesion technology, which is applied in the field of asphalt pavement materials, can solve the problems of high mutual repellency of asphalt or stone materials, unsuitable promotion and application, and high production costs, so as to improve adhesion, water damage resistance, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An anti-stripping agent for improving the adhesion between asphalt and stone materials, which consists of the following components in mass percentage:

[0016] Aluminum trichloride hexahydrate: 4Kg;

[0017] Drinking water: 996Kg.

[0018] The preparation method of the above-mentioned anti-stripping agent for improving the adhesion of asphalt and stone materials is to mix 4Kg of aluminum trichloride hexahydrate and 996Kg of drinking water at normal temperature by mass percentage, and stir evenly to make a concentration of 4‰ aluminum trichloride hexahydrate. aluminum solution.

[0019] The specific application of using the above-mentioned aluminum chloride hexahydrate aqueous solution to improve the adhesion between asphalt and stone:

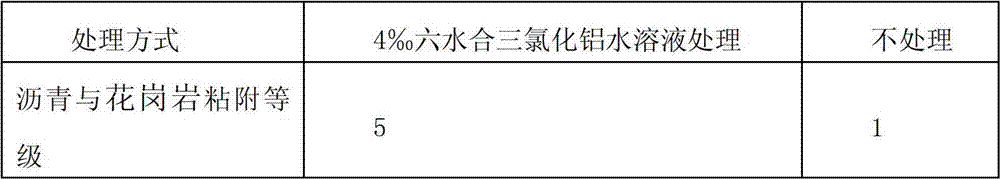

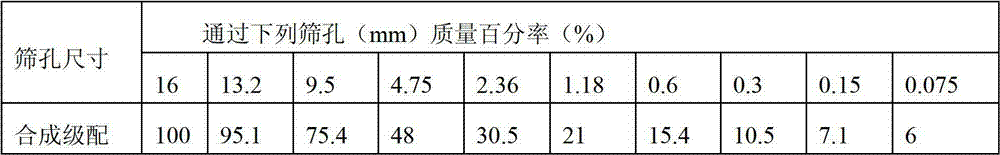

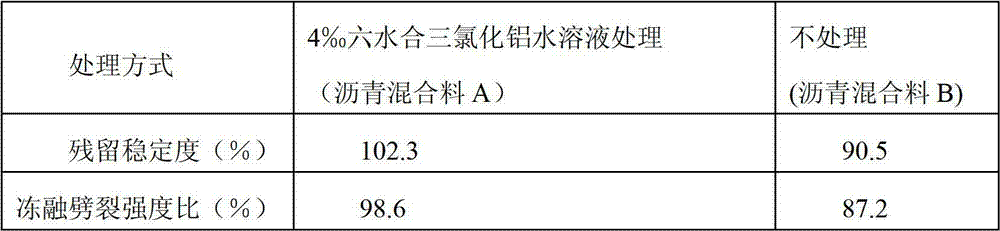

[0020] The asphalt used in a certain project is 70# matrix asphalt, and the stone material is granite.

[0021] ⑴. Use the above-mentioned aluminum chloride hexahydrate aqueous solution to infiltrate the granite aggregate, and take it...

Embodiment 2

[0037] A substance that improves the adhesion between asphalt and stone materials, consisting of the following components in mass percentage:

[0038] Aluminum trichloride hexahydrate: 5Kg;

[0039] Drinking water: 995Kg.

[0040] The above-mentioned preparation method for improving the adhesion between asphalt and stone materials is to mix 5Kg of aluminum chloride hexahydrate and 995Kg of drinking water at normal temperature by mass percentage, and stir evenly to make an aqueous solution of aluminum chloride hexahydrate with a concentration of 5‰ .

[0041] The specific application of using the above-mentioned aluminum chloride hexahydrate aqueous solution to improve the adhesion between asphalt and stone:

[0042] The asphalt used in a certain project is SBS matrix asphalt, and the stone material is basalt.

[0043] ⑴. Use the above-mentioned aluminum chloride hexahydrate aqueous solution to infiltrate the basalt aggregate, and take it out immediately after the surface of...

Embodiment 3

[0059] A substance that improves the adhesion between asphalt and stone materials, consisting of the following components in mass percentage:

[0060] Aluminum trichloride hexahydrate: 6Kg;

[0061] Drinking water: 994Kg.

[0062] The above-mentioned preparation method for improving the adhesion between asphalt and stone materials is to mix 6Kg of aluminum trichloride hexahydrate and 994Kg of drinking water at normal temperature by mass percentage, and stir evenly to make an aqueous solution of aluminum trichloride hexahydrate with a concentration of 6‰ .

[0063] The specific application of using the above-mentioned aluminum chloride hexahydrate aqueous solution to improve the adhesion between asphalt and stone:

[0064] The asphalt used in a certain project is SBS matrix asphalt, and the stone material is basalt.

[0065] ⑴. Use the above-mentioned aluminum chloride hexahydrate aqueous solution to infiltrate the basalt aggregate, and take it out immediately after the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com