Method for preparing ultrafine silver powder by directly performing thermal decomposition on silver nitrate

A technology of ultra-fine silver and silver nitrate is applied in the preparation of ultra-fine silver powder, and in the field of preparing ultra-fine silver powder by direct thermal decomposition of silver nitrate, which can solve the problems of high pyrolysis temperature, unable to obtain silver powder, poor monodispersity and the like, and achieve purity High, good product quality, high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

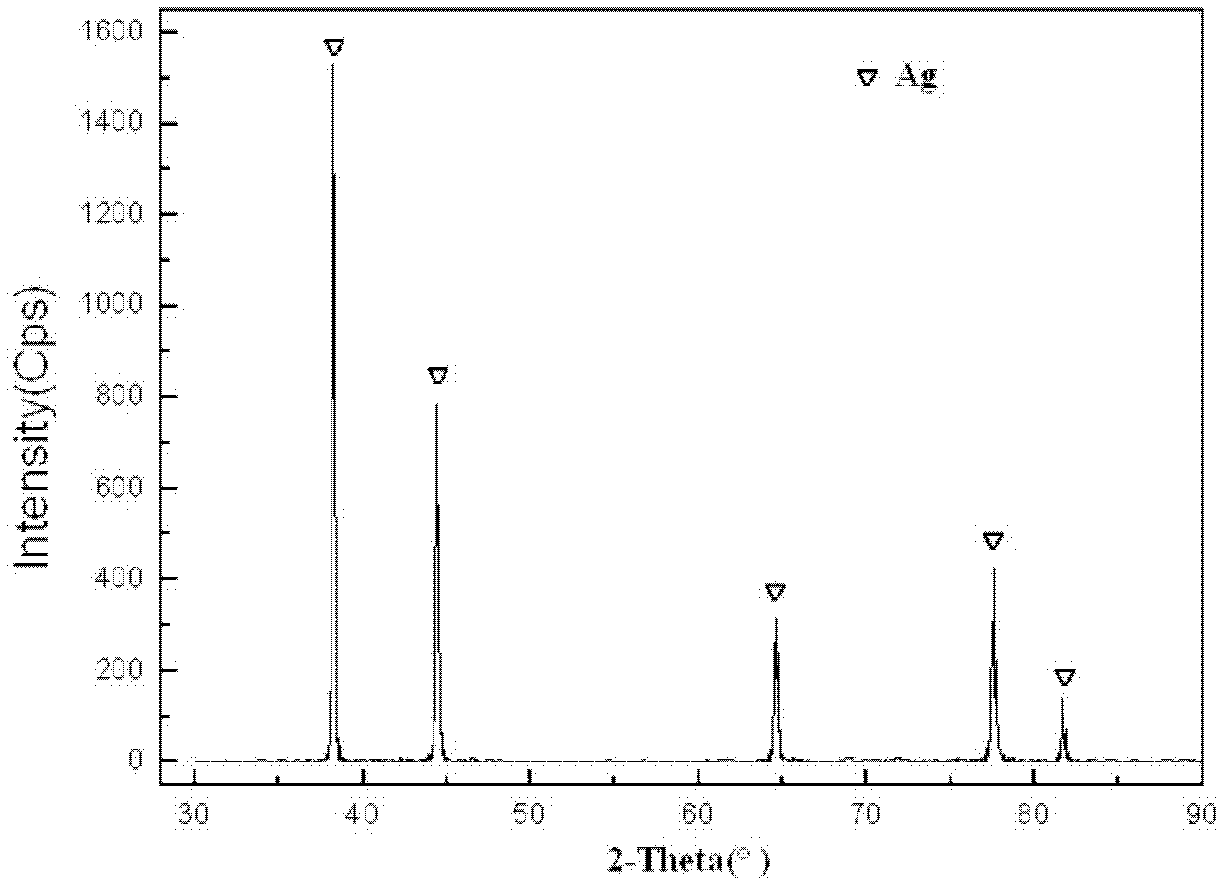

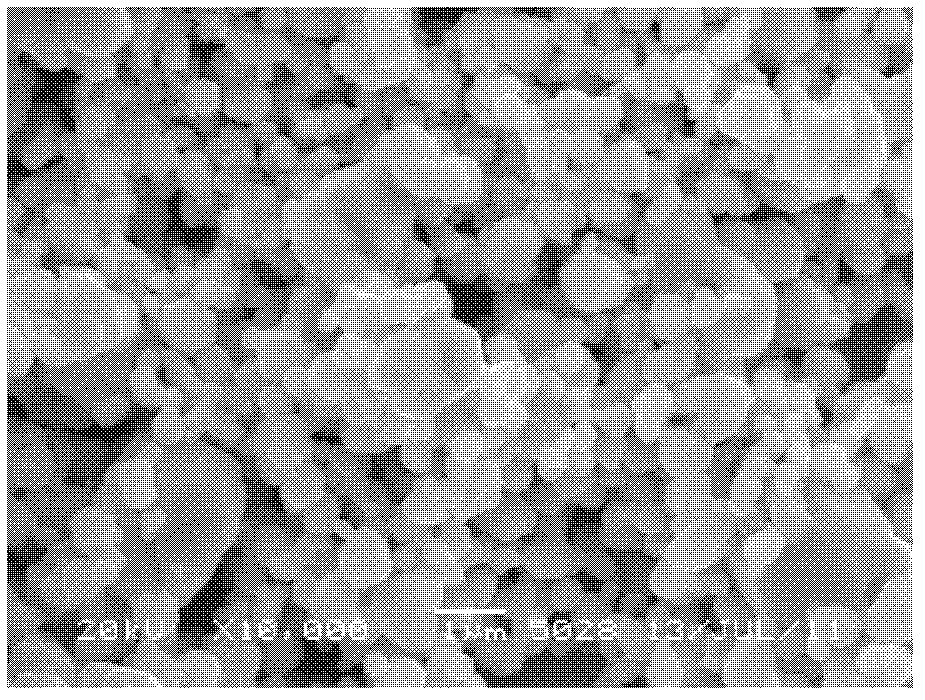

[0022] Put the crucible containing 40g of silver nitrate solid into a tube furnace, heat it to 440°C at a heating rate of 5°C / min, and feed air with a relative humidity of 80-85%, and the air flow rate is 400-500ml / min , After calcination for 6 hours, stop heating and ventilating, cool to room temperature, collect the solid product in the crucible, and obtain the superfine silver powder product. The X-ray diffraction analysis spectrum of gained silver powder is as figure 1 As can be seen from the figure, except for the characteristic peak of silver, there is no other impurity phase, and the characteristic peak of the sample is narrow and sharp, indicating that the obtained silver powder has a high degree of crystallinity. The scanning electron microscope photograph of gained silver powder is as figure 2 As shown, it can be seen from the figure that the appearance of the obtained silver powder is a spherical particle, and the average particle size is about 1.5um.

Embodiment 2

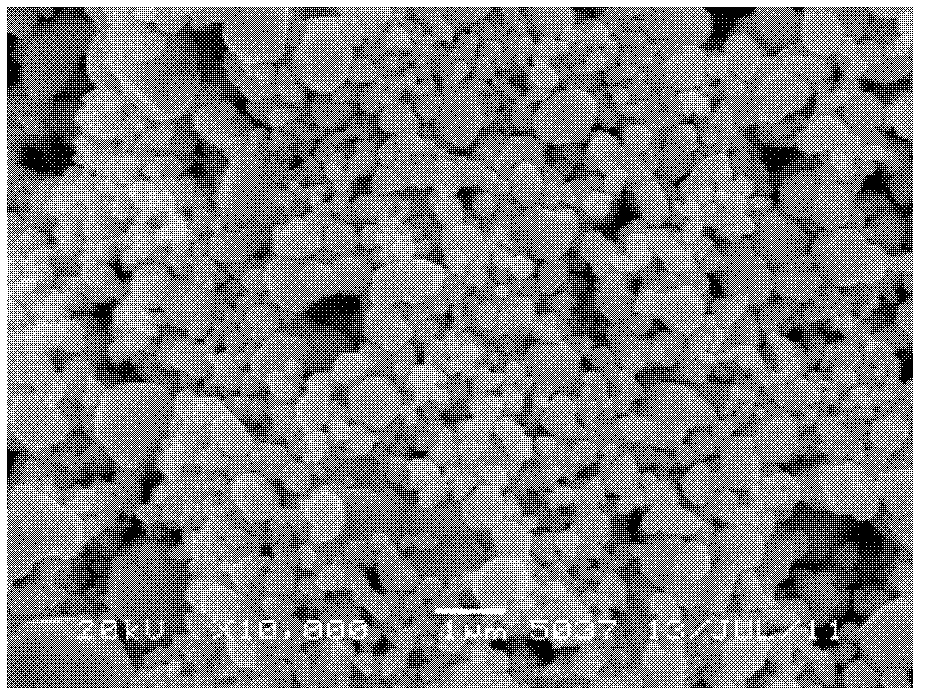

[0024] Put the crucible containing 40g of silver nitrate solid into a tube furnace, heat it to 520°C at a heating rate of 20°C / min, and feed air with a relative humidity of 85-90%, and the air flow rate is 600-800ml / min , after calcining for 4h, stop heating and ventilating, cool to room temperature, collect the solid product in the crucible, obtain the ultrafine silver powder product and get the scanning electron micrograph of the silver powder as follows image 3 As shown, it can be seen from the figure that the appearance of the obtained silver powder is a spherical particle, and the average particle size is about 0.8um.

Embodiment 3

[0026] Put the crucible containing 40g of silver nitrate solid into a tube furnace, heat it to 400°C at a heating rate of 35°C / min, and feed air with a relative humidity of 80-85%, and the air flow rate is 200-300ml / min , After calcination for 8 hours, stop heating and ventilating, cool to room temperature, collect the solid product in the crucible, and obtain the superfine silver powder product. The appearance of the obtained silver powder is spherical particles, and the particle size of the silver powder is 1.2um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com