Hierarchical structure gaphene-based tensile tansparent conductive elastomer preparation method

A transparent conductive and elastic body technology, which is applied in the direction of cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of unrealized stretchability of transparent conductive films, damage to the integrity of conductive layers, loss of conductivity, etc. , to achieve the effect of simple preparation method, good stretchability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

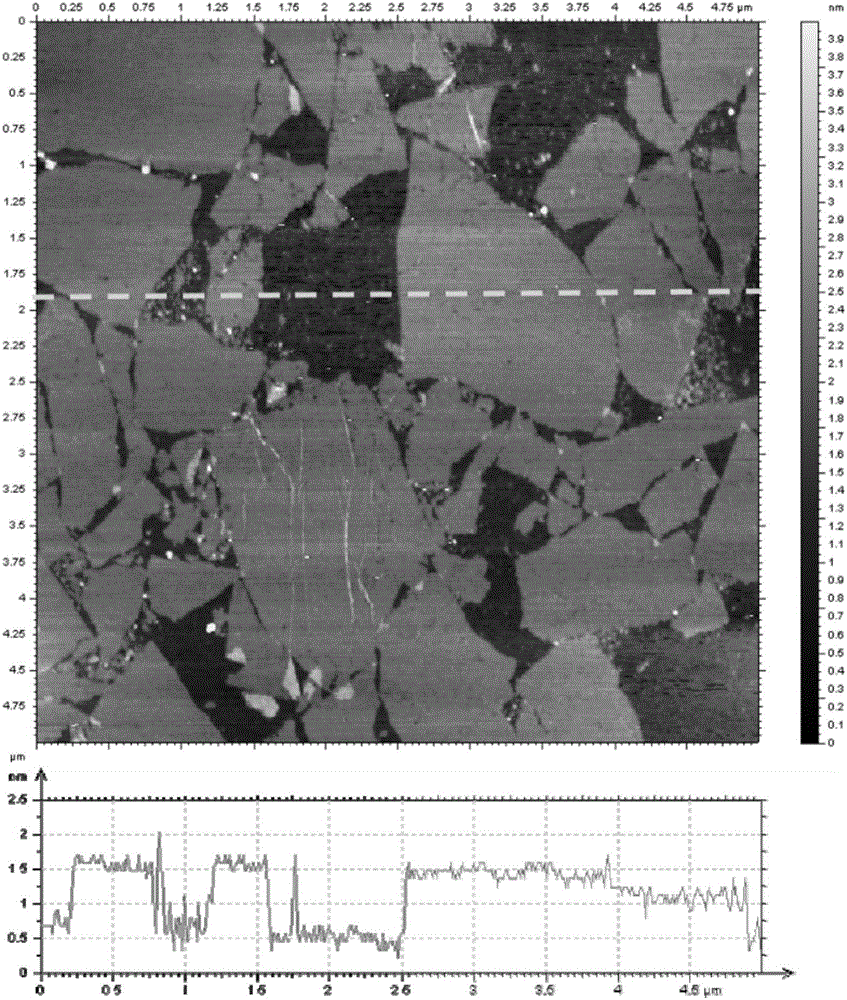

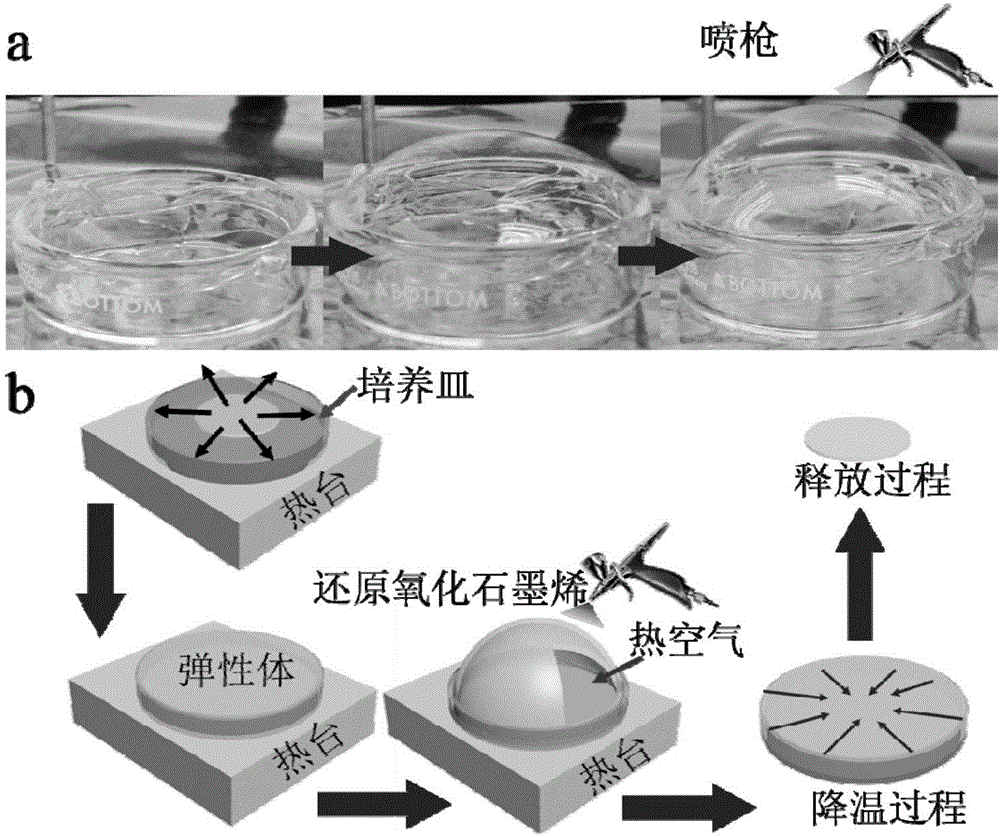

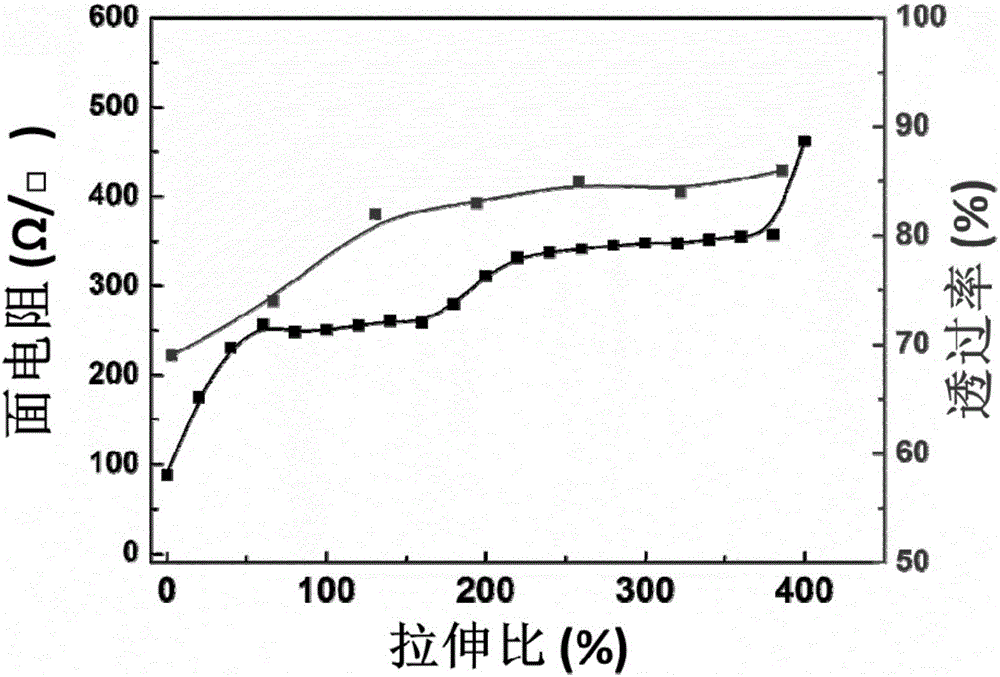

[0033] Graphene oxide is prepared by the method reported in the literature (Journal of the American Chemical Society 1958,80,1339-1339.), disperse 2mg graphite oxide powder into 100mL deionized water, and use a cell pulverizer to sonicate for 0.5 hours to obtain a brown translucent Graphene oxide aqueous solution, by scanning probe microscopy (such as figure 1 ) analysis shows that the graphene oxide prepared by this method has a thickness of about 1nm, which is a single-layer graphene with better quality. 3 mL of ammonia water (25%) was added to the graphene oxide dispersion at one time, and magnetically stirred for 1 hour to mix the two evenly. Subsequently, the pH of the mixed solution was measured to be about 9 with a pH meter. Weigh 1 mg of hydrazine hydrate solution and add it dropwise to the stirring graphene oxide solution, and then heat the mixed liquid to 85 °C with a heating platform. Keep it warm for 2 hours while stirring and sealing, and the graphene oxide red...

Embodiment 2

[0035]Graphene oxide was prepared by the method reported in the literature (Journal of the American Chemical Society 1958,80,1339-1339.), 4 mg of graphite oxide was dispersed into 100 mL of deionized water, and ultrasonically used for 0.5 hours with a cell pulverizer to obtain a brown translucent The graphene oxide aqueous solution, through the analysis of the scanning probe microscope, shows that the thickness of the graphene oxide prepared by this method is about 1nm, which is a single-layer graphene with good quality. 10 mL of ammonia water (25%) was added to the graphene oxide dispersion at one time, and magnetically stirred for 1 hour to mix the two evenly. Subsequently, the pH of the mixture was measured to be about 11 with a pH meter. Weigh 2 mg of hydrazine hydrate solution and add it dropwise to the stirring graphene oxide solution, and then heat the mixed liquid to 95° C. with a heating platform. Keep it warm for 4 hours while stirring and sealing, and the graphene ...

Embodiment 3

[0037] Graphene oxide was prepared by the method reported in the literature (Journal of the American Chemical Society 1958,80,1339-1339.), disperse 10mg graphite oxide into 100mL deionized water, and use a cell pulverizer to sonicate for 0.5 hours to obtain a brown translucent The graphene oxide aqueous solution, through the analysis of the scanning probe microscope, shows that the thickness of the graphene oxide prepared by this method is about 1nm, which is a single-layer graphene with good quality. 10 mL of ammonia water (25%) was added to the graphene oxide dispersion at one time, and magnetically stirred for 1 hour to mix the two evenly. Subsequently, the pH of the mixture was measured to be about 11 with a pH meter. Weigh 2 mg of hydrazine hydrate solution and add it dropwise to the stirring graphene oxide solution, and then heat the mixed liquid to 95° C. with a heating platform. Keep it warm for 4 hours while stirring and sealing, and the graphene oxide reduction proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com