Polyethylene composition and film thereof

A technology of polyethylene and composition, which is applied in the field of polyethylene composition and its film, and can solve the problems of poor film formation and easy cracking of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

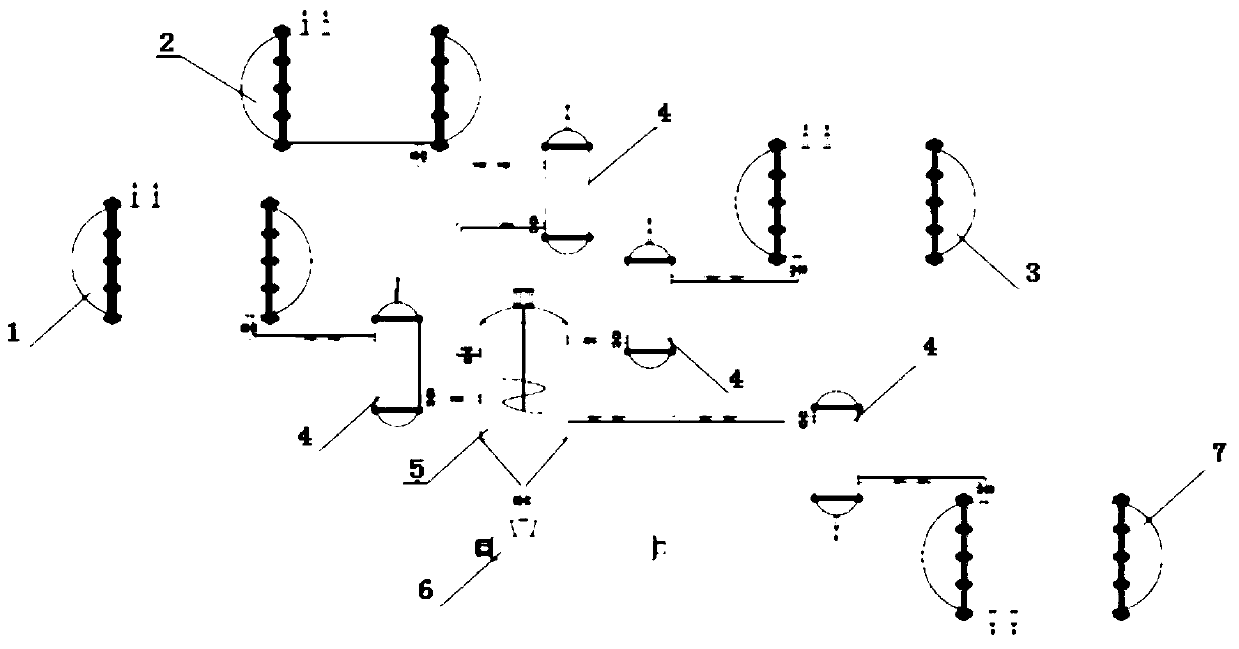

[0037] According to a preferred embodiment of the present invention, the polyethylene composition is figure 1 Prepared in the multi-reactor parallel device shown, the multi-reactor parallel device includes a first reactor 1, a second reactor 2, a third reactor 3, a fourth reactor 7, solid / liquid (gas) The separator 4, the homogenization silo 5 and the melt granulation system 6, wherein the first reactor 1, the second reactor 2, the third reactor 3 and the fourth reactor 7 are connected in parallel, and the solid / The number of liquid (gas) separators 4 is four, which are respectively connected to the first reactor 1, the second reactor 2, the third reactor 3 and the fourth reactor 7. The group prepared by the first reactor 1 Component A, component B prepared by the second reactor 2, component C prepared by the third reactor 3, and component D prepared by the fourth reactor 7 are separated in different solid / liquid (gas) separations. The phase separation is carried out in the v...

Embodiment 1

[0056] This example is used to illustrate the polyethylene composition and barrier film provided by the present invention.

[0057] (1) Preparation of polyethylene composition:

[0058] The polyethylene composition provided in this embodiment is composed of component A, component B, component C, component D and component E, wherein component A, component B, component C and component D are all Ethylene-α olefin copolymerized linear low density polyethylene (LLDPE), and all adopt the same catalyst system (Ziegler-Natta catalyst, which is prepared by CN101838351A Example 1 of the Ziegler-Natta catalyst system, below Same) and polymerization process, the difference lies in the amount of hydrogen added when preparing different components and the type and molar content of alpha olefin comonomer; component E is POE barrier masterbatch P1. Specific steps are as follows:

[0059] Add ethylene, alpha olefin, hydrogen and nitrogen (ethylene, alpha olefin, hydrogen and nitrogen are all polymer...

Embodiment 2

[0070] This example is used to illustrate the polyethylene composition and barrier film provided by the present invention.

[0071] (1) Preparation of polyethylene composition:

[0072] The polyethylene composition provided in this embodiment is composed of component A, component B, component C, component D and component E, wherein component A, component B, component C and component D are all Linear low-density polyethylene (LLDPE) copolymerized with ethylene and alpha olefins are prepared by using the same catalyst system (Ziegler-Natta catalyst) and polymerization process. The difference lies in the amount of hydrogen added when preparing different components and alpha The type and molar content of olefin comonomers are different; component E is POE barrier masterbatch P1. Specific steps are as follows:

[0073] Add ethylene, alpha olefins, hydrogen and nitrogen into the fluidized bed gas phase reactor, then add the Ziegler-Natta catalyst system, and then polymerize at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com