Antibacterial composition and thin film thereof

An antibacterial composition and composition technology, applied in the field of antibacterial composition and its film, can solve the problems of easy rupture of film and poor film forming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

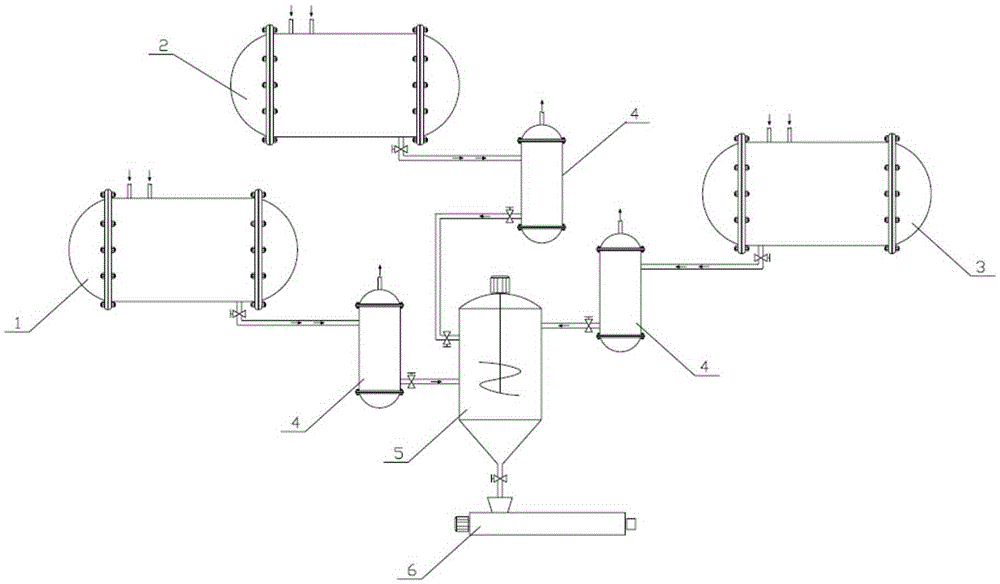

[0037]According to a preferred embodiment of the present invention, the antibacterial composition is prepared in a multi-reactor parallel device as shown in Figure 1, and the multi-reactor parallel device includes a first reactor 1 and a second reactor 2 , the third reactor 3, solid / liquid (gas) separator 4, homogenizing silo 5 and melting granulation system 6, wherein, the first reactor 1, the second reactor 2 and the third reactor 3 Connected in parallel, the number of the solid / liquid (gas) separator 4 is three, communicated with the first reactor 1, the second reactor 2 and the third reactor 3 respectively, prepared by the first reactor 1 Component A, the component B prepared by the second reactor 2 and the component C prepared by the third reactor 3 carry out phase separation in different solid / liquid (gas) separators 4 respectively, and then the phase The separated component A, component B and component C are transported to the homogenizing silo 5 in proportion and mixed...

Embodiment 1

[0052] This embodiment is used to illustrate the antibacterial composition and film thereof provided by the present invention.

[0053] (1) Preparation of antibacterial composition:

[0054] The polyethylene composition that this embodiment provides is made up of component A, component B and component C, and these three kinds of components are the linear low density polyethylene (LLDPE) of ethylene / alpha olefin copolymerization, wherein, component A And component B adopts Ziegler-Natta catalyst to prepare (the Ziegler-Natta catalyst system is the Ziegler-Natta catalyst system prepared by CN101838351A embodiment 1, the same below), component C It is prepared by using a metallocene catalyst (the metallocene catalyst system is the supported metallocene catalyst prepared in Example 1 of CN102453124A, the same below). Specific steps are as follows:

[0055] Add ethylene, α-olefin, hydrogen and nitrogen (ethylene, α-olefin, hydrogen and nitrogen are of polymerization grade, used a...

Embodiment 2

[0065] This embodiment is used to illustrate the antibacterial composition and film thereof provided by the present invention.

[0066] (1) Preparation of antibacterial composition:

[0067] The polyethylene composition that this embodiment provides is made up of component A, component B and component C, and these three kinds of components are the linear low density polyethylene (LLDPE) of ethylene / alpha olefin copolymerization, wherein, component A And component B is prepared by Ziegler-Natta catalyst, and component C is prepared by metallocene catalyst. Specific steps are as follows:

[0068] Add ethylene, alpha olefin, hydrogen and nitrogen into the fluidized bed gas phase reactor, then add the catalyst system, and then polymerize under the conditions of temperature 84-88°C and pressure 1.8-2.0MPa to obtain components A, Component B and Component C. Among them, the control of the melt index of component A, component B and component C is realized by adjusting the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Puncture strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com