Semihard aluminum wire, overhead wire and preparation method of semihard aluminum wire

A technology for overhead power transmission wires and hard aluminum, which is applied in the direction of root rod/rod/wire/strip conductor, and the manufacture of extensible conductors/cables, etc. Complexity and other issues, to achieve the effect of simple and convenient construction, energy-saving construction characteristics, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

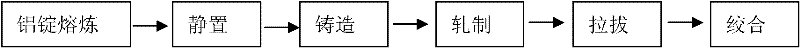

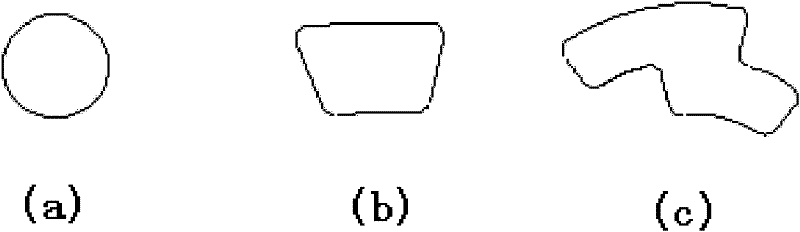

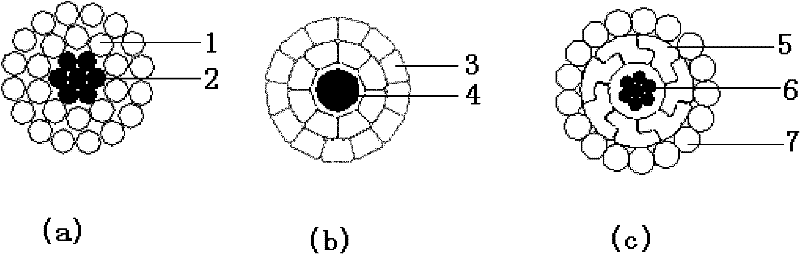

[0038] Such as figure 1 The schematic diagram of the preparation process of aluminum rod, semi-hard aluminum single wire and overhead transmission wire is shown. The main process includes aluminum ingot smelting, casting, rolling, drawing, stranding and other processes. The specific steps are as follows:

[0039] Aluminum ingots with an aluminum content of not less than 99.70% are selected and melted in a shaft furnace; then the molten aluminum is refined in a holding furnace at a refining temperature of 710-730°C, first using solid refining flux NaCl (the amount of NaCl added is 8kg / t aluminum liquid) to cover the surface of the aluminum liquid for refining treatment, and then use a chlorine-nitrogen mixed gas to blow into the aluminum liquid (the volume percentage of chlorine in the chlorine-nitrogen mixed gas is 20%) for refining treatment, and then the aluminum liquid is static Leave for 50 minutes. When the aluminum liquid flowing out from the holding furnace passes thr...

Embodiment 2

[0047] Aluminum ingots with an aluminum content of not less than 99.70% are selected and melted in a shaft furnace; then the molten aluminum is refined in a holding furnace at a refining temperature of 710-730°C, and the solid refining flux CaF is first used 2 (CaF 2 The amount of addition is 6kg / t aluminum liquid) to cover the surface of the aluminum liquid for refining treatment, and then use a chlorine-nitrogen mixed gas to blow into the aluminum liquid (the volume percentage of chlorine in the chlorine-nitrogen mixed gas is 20%) for refining treatment, Then the molten aluminum was left to stand for 50 minutes. When the aluminum liquid flowing out from the holding furnace passes through the launder, it is filtered by foam ceramic bricks (the main impurity elements and their weight percentages in the filtered aluminum liquid are controlled as: Si≤0.11%, Fe≤0.25%, Cu≤0.01 %, V+Ti+Mn+Cr≤0.02%), and then enter the crystallization wheel of the casting machine for continuous cas...

Embodiment 3

[0054] Aluminum ingots with an aluminum content of not less than 99.70% are selected and melted in a shaft furnace; then the molten aluminum is refined in a holding furnace at a refining temperature of 710-730°C, first using solid refining fluxes NaCl and KCl (addition of NaCl The amount is 3kg / t aluminum liquid, and the addition amount of KCl is 4kg / t aluminum liquid) to cover the surface of aluminum liquid for refining treatment, then adopt chlorine-nitrogen mixed gas to blow into aluminum liquid (the volume of chlorine gas in the chlorine-nitrogen mixed gas is 100% Min content is 20%) carry out refining treatment, then aluminum liquid stands still for 40 minutes. When the aluminum liquid flowing out from the holding furnace passes through the launder, it is filtered by foam ceramic bricks (the main impurity elements and their weight percentages in the filtered aluminum liquid are controlled as: Si≤0.11%, Fe≤0.25%, Cu≤0.01 %, V+Ti+Mn+Cr≤0.02%), and then enter the crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com