Method for producing DC variable frequency enameled wire

A technology of DC frequency conversion and production method, which is used in cable/conductor manufacturing, plastic/resin/wax insulators, organic insulators, etc., can solve the problems of compressor burnout, fast winding speed, large tension, etc., and achieve surface lubricity improvement. , excellent wear resistance, the effect of ensuring insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

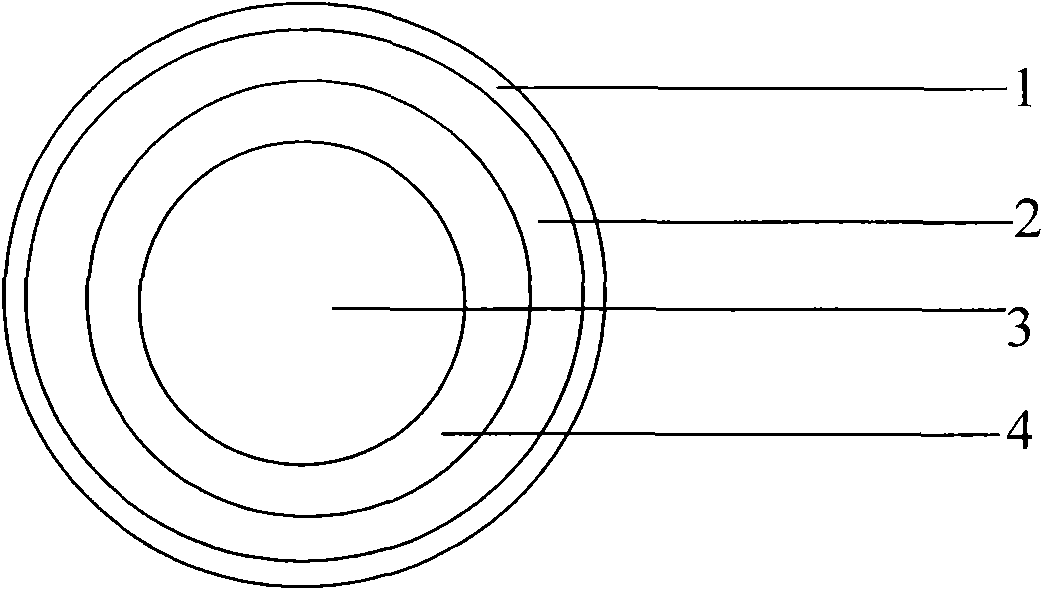

[0021] The production method of the DC frequency conversion enameled wire of the present invention is illustrated in conjunction with the accompanying drawings and embodiments

[0022] According to the performance requirements of the DC inverter compressor and the particularity of the winding method of the DC compressor coil, that is, the winding speed is fast, the copper wire is stretched, and the copper wire is scratched during the winding process. Some properties, such as the softness, surface lubricity and wear resistance of the enameled wire, have been improved to meet the special winding requirements of the enameled wire for DC inverter compressors.

[0023] In order to produce enameled wires that meet the needs of DC inverter compressor motors, a long period of exploration was carried out in the selection of raw materials and production processes, and after several rounds of PDCA cycle planning. Special requirements for the above three indicators of enameled wire, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com