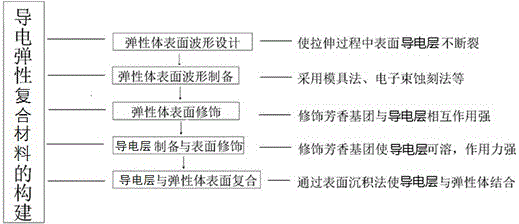

Constructing and preparation scheme of conductive elastic composite material

An elastic composite material and composite material technology are applied in the field of construction and preparation of conductive elastic composite materials, which can solve problems such as limiting the application of stretchable electronics, large resistance of conductive elastomers, and unstable resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example. Construction of a conductive elastomer and repeated tensile test experiment

[0022] (1) Use sebs to add talc powder and stir evenly, and use the composite as the basic structural unit of the elastomer.

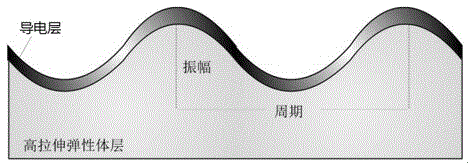

[0023] (2) Carry out the surface design of the elastomer prepared above and process the period and amplitude. The processing method adopts the template method. The designed surface waveform is a sine wave and the waveform period is 20 microns. The amplitude is 20 microns.

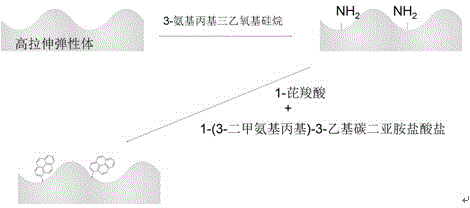

[0024] (3) After constructing the basic periodic structure, modify the surface of the elastomer and introduce aromatic groups-pyrene. The specific route is to use a silane coupling agent to introduce surface active amino groups, and then use carbodiimide coupling to form an amide bond to introduce aromatic groups, such as image 3 Shown.

[0025] (4) The conductive layer of the elastic conductor is made of large-size soluble conductive graphene, and the surface of the graphene is modified with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com