Preparation method of Cu/C composite wire rod

A composite wire and alloy ingot technology, applied in the direction of metal/alloy conductors, root rods/rods/wires/strip conductors, conductive materials, etc., can solve the uncoordinated deformation of copper and carbon, weak interface bonding strength, and twisted wire core wires and other problems, to achieve uniform distribution, improve the bonding strength, and improve the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

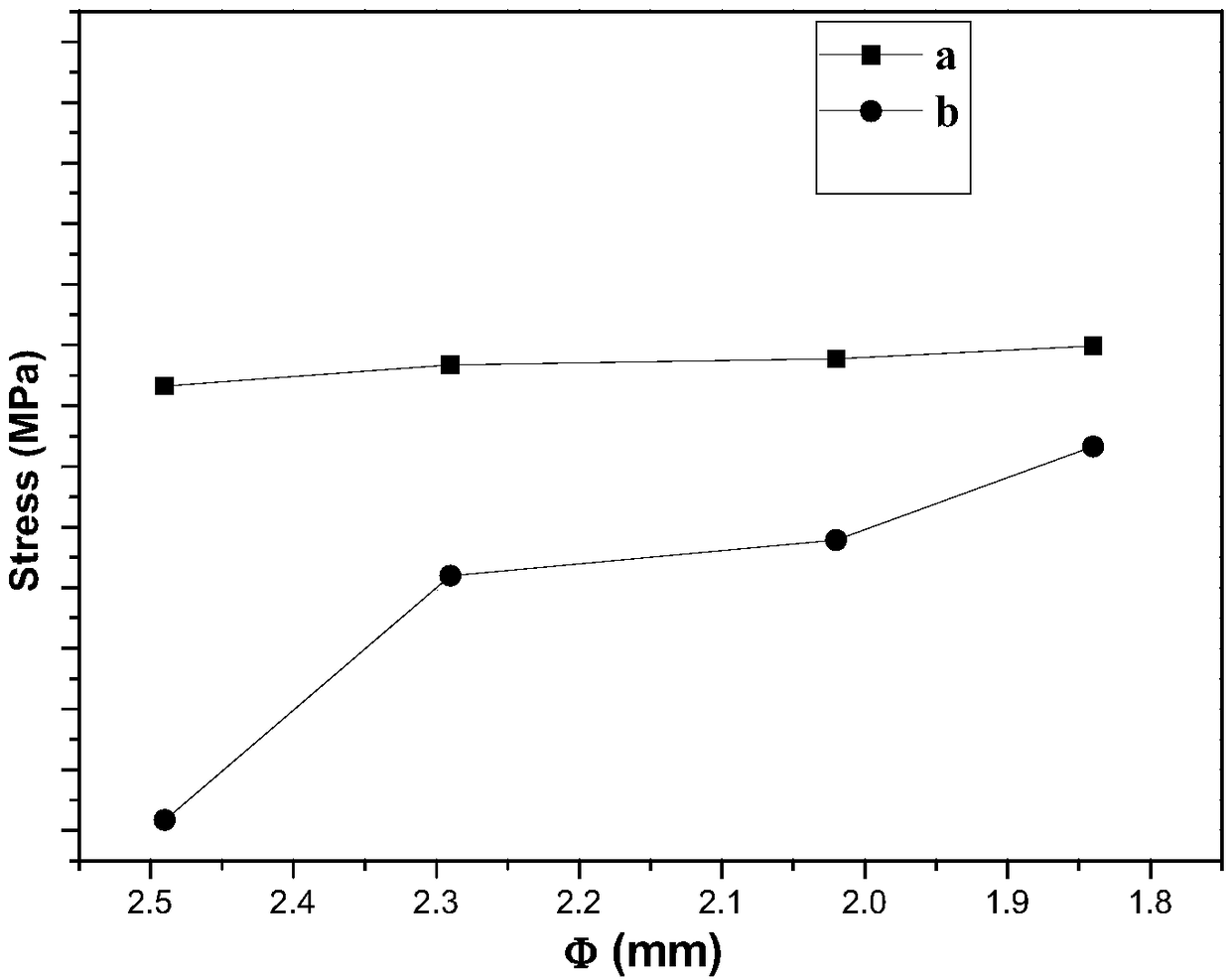

[0028] The preparation method of the present embodiment comprises the following steps:

[0029] Step 1. Place the oxygen-free copper block in a vacuum induction furnace for high-temperature melting at a temperature of 1100 ° C. The melting time is 3 hours. The oxygen-free copper block has been completely smelted; the oxygen-free copper block The mass content of copper in the body is not less than 99.95%;

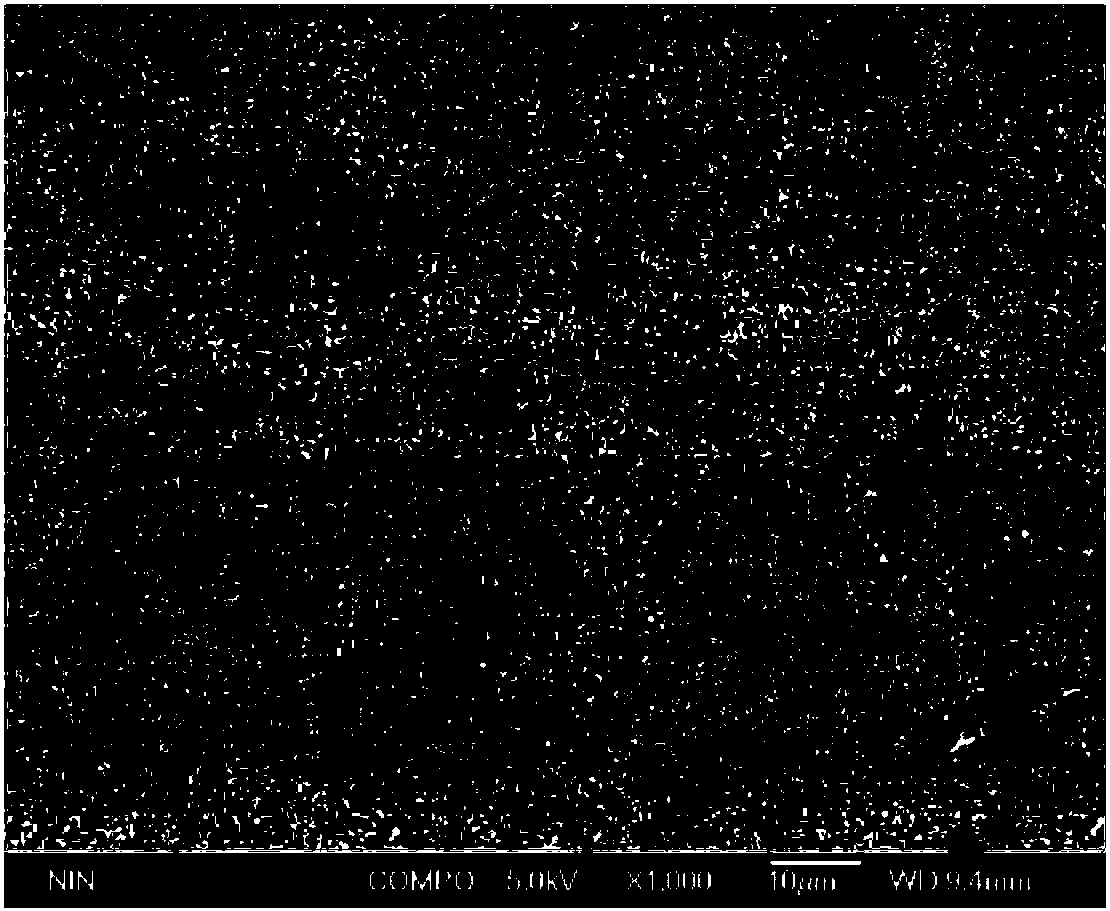

[0030] Step 2. Slowly and evenly pour the fully smelted high-temperature copper liquid in the smelting furnace in step 1 into the crucible equipped with porous and bulky graphene oxide colloids. The structure of the porous and bulky graphene oxide colloids is similar In the honeycomb, cooling in a water bath forms a cylindrical Cu / C alloy ingot, the diameter of the Cu / C alloy ingot is Φ60mm, the quality of the high-temperature copper liquid is 10% of the quality of the porous graphene colloid, and the pouring time is 5s; The graphene oxide colloid in the loose state is obta...

Embodiment 2

[0048] The preparation method of the present embodiment Cu / C composite wire comprises the following steps:

[0049] Step 1. Place the oxygen-free copper block in a vacuum induction furnace for high-temperature melting at a temperature of 1200 ° C. The melting time is 4.5 hours. The oxygen-free copper block has been completely smelted; the oxygen-free copper The mass content of copper in the block is not less than 99.95%;

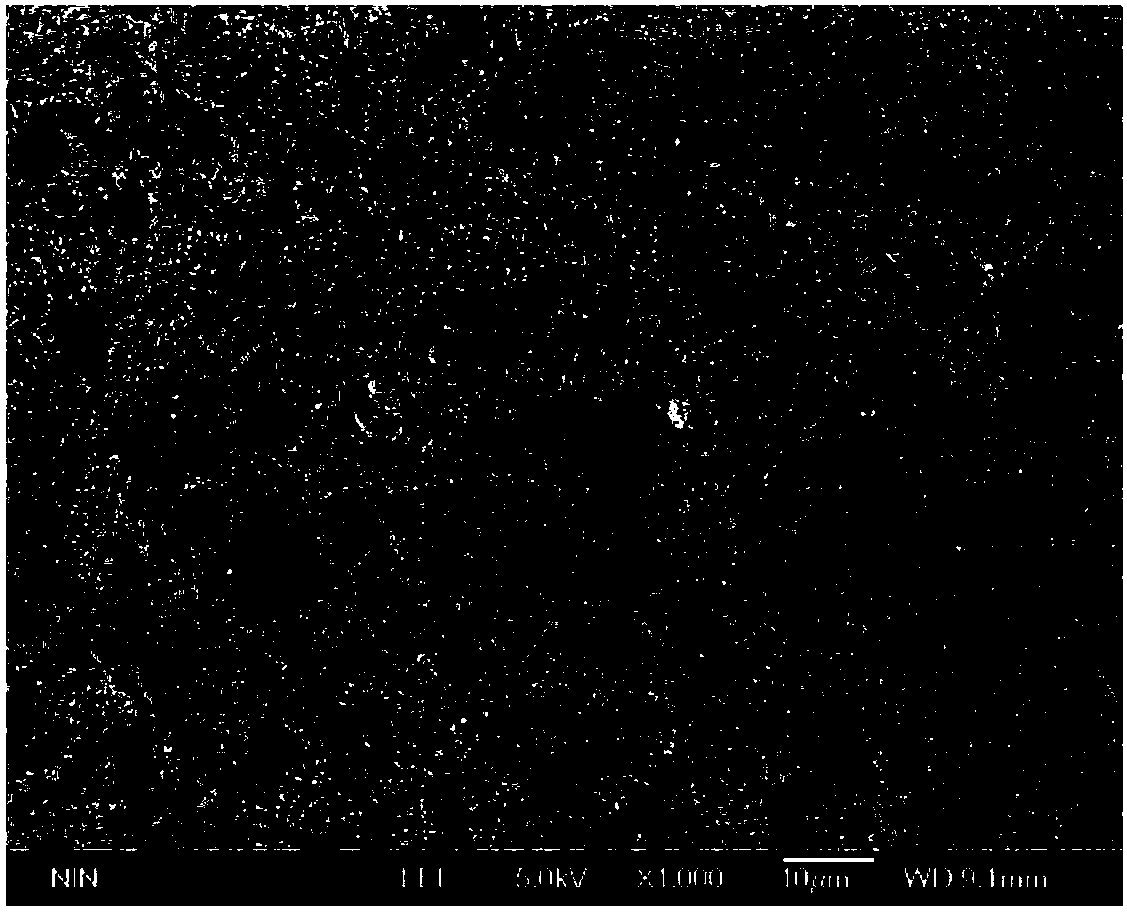

[0050] Step 2. Slowly and evenly pour the fully smelted high-temperature copper liquid in the smelting furnace in step 1 into the crucible equipped with porous and bulky graphene oxide colloids. The structure of the porous and bulky graphene oxide colloids is similar In the honeycomb, cooling in a water bath forms a cylindrical Cu / C alloy ingot, the diameter of the Cu / C alloy ingot is Φ60mm, the quality of the high-temperature copper liquid is 20% of the quality of the porous graphene colloid, and the pouring time is 6s; The graphene oxide colloid in the lo...

Embodiment 3

[0056] The preparation method of the present embodiment Cu / C composite wire comprises the following steps:

[0057] Step 1. Place the oxygen-free copper block in a vacuum induction furnace for high-temperature melting at a temperature of 1300°C. The melting time is 4.5 hours. The oxygen-free copper block has been completely smelted; the oxygen-free copper The mass content of copper in the block is not less than 99.95%;

[0058] Step 2. Slowly and evenly pour the fully smelted high-temperature copper liquid in the smelting furnace in step 1 into the crucible equipped with porous and bulky graphene oxide colloids. The structure of the porous and bulky graphene oxide colloids is similar In the honeycomb, cooling in a water bath forms a cylindrical Cu / C alloy ingot, the diameter of the Cu / C alloy ingot is Φ60mm, the quality of the high-temperature copper liquid is 30% of the quality of the porous graphene colloid, and the pouring time is 7s; The graphene oxide colloid in the loos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com