ReBCO high temperature superconducting wire bonding device and bonding method using same

A high-temperature superconducting and superconducting wire technology, applied in superconducting components, superconducting/high-conducting conductors, welding/welding/cutting items, etc., can solve problems such as system instability and refrigerant evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

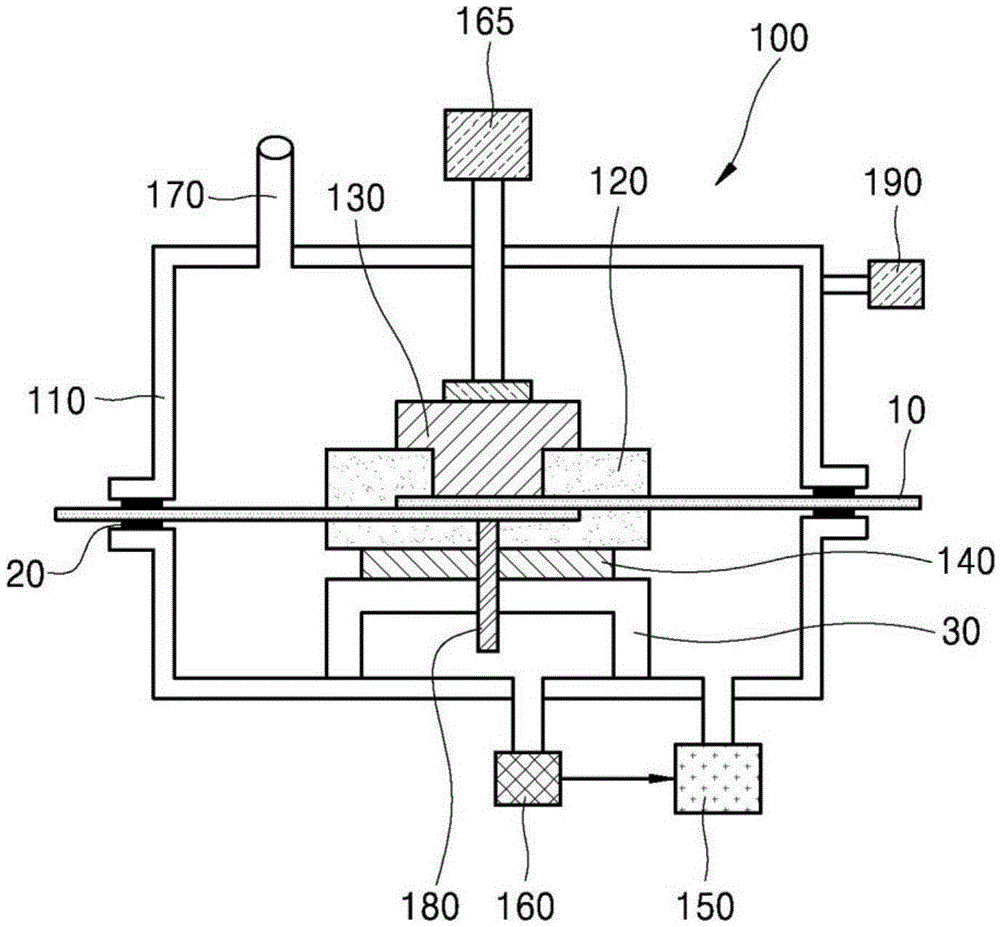

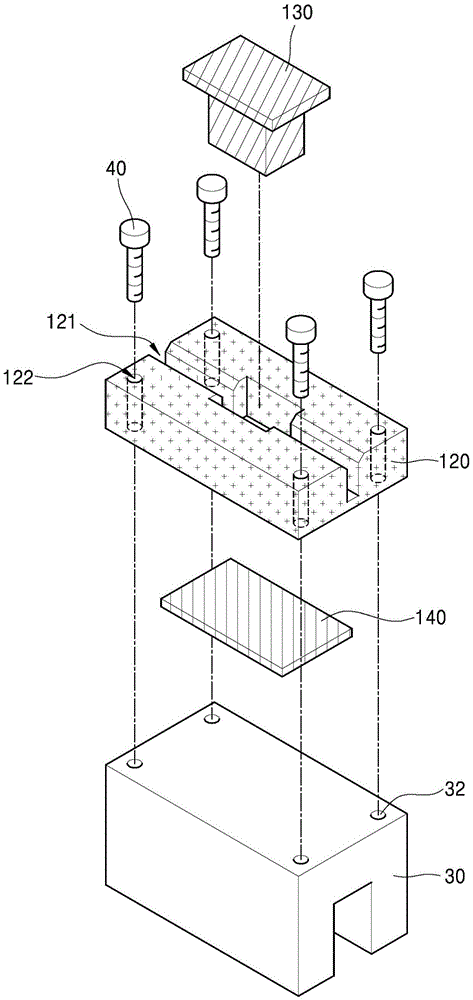

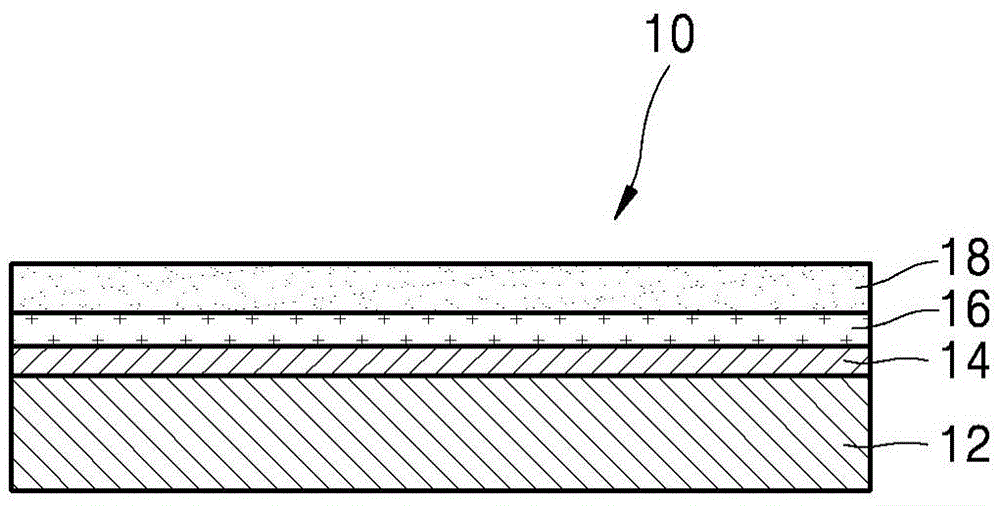

[0032] The embodiments described in detail below with reference to the accompanying drawings make the advantages and features of the present invention and the methods for achieving these advantages and features more clear. However, the present invention is not limited to the embodiments disclosed below, and can be implemented in various ways different from each other. This embodiment is only used to make the disclosure of the present invention more complete and contribute to the common technology in the technical field of the present invention. Personnel fully understand the scope of the invention, and the invention is defined according to the scope of protection of the invention. Throughout the specification, the same reference numerals refer to the same structural elements.

[0033] Hereinafter, referring to the drawings, a second-generation ReBCO high-temperature superconducting wire bonding device and a bonding method using the same according to a preferred embodiment of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com