Method for manufacturing copper-clad aluminum composite panel belt

A composite strip and manufacturing method technology, applied in the manufacture of extensible conductors/cables, metal rolling, metal/alloy conductors, etc., can solve the problems of difficult mass production, high manufacturing difficulty, low production efficiency, etc. The effect of meeting application needs, reducing the number of intermediate annealing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

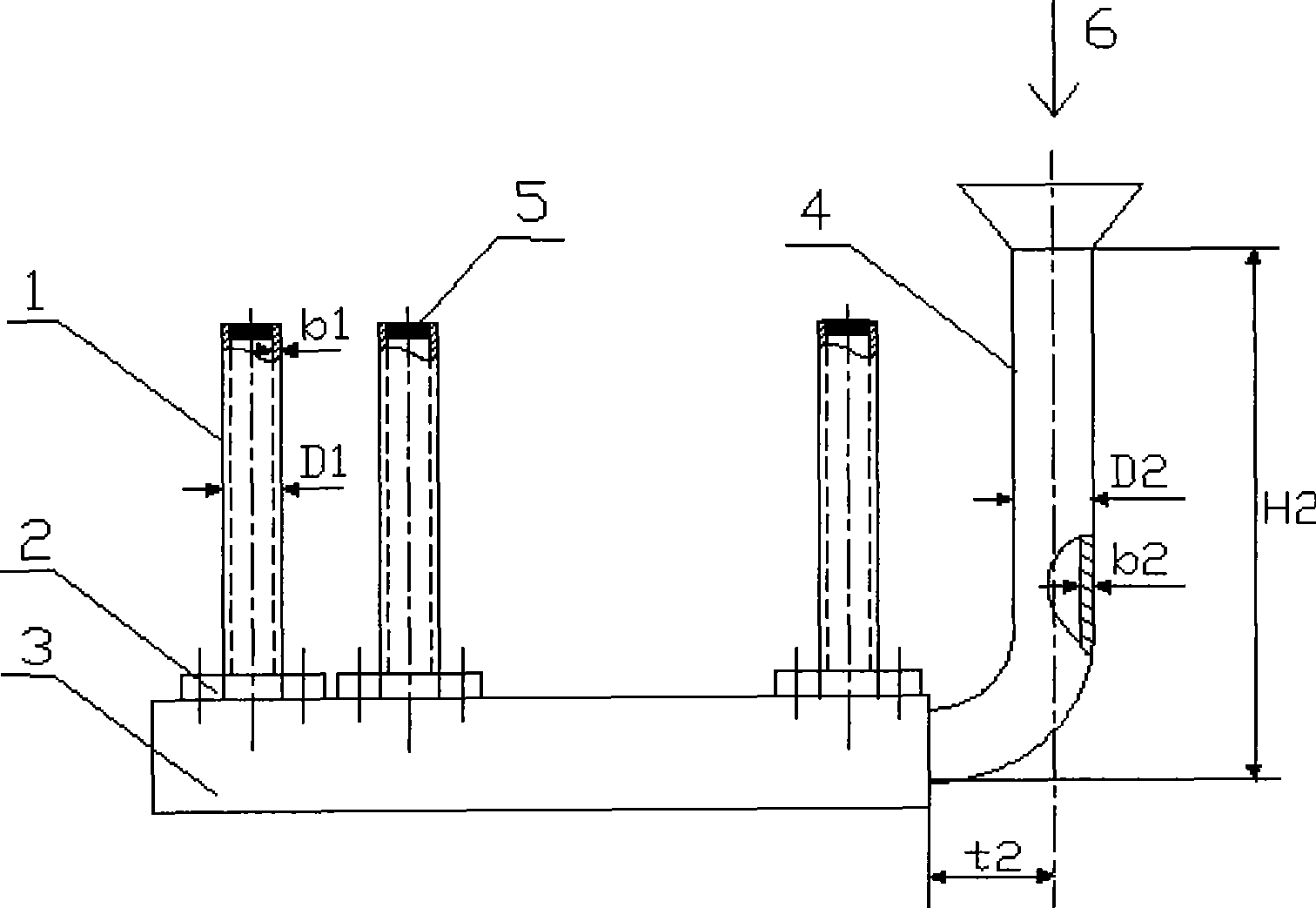

[0039] Step 1: Preparation of copper-clad aluminum core-clad casting billet

[0040] 〔1〕The outer diameter D of 8 1 50mm wall thickness b 1 1mm length H 1 The inner wall of the 900mm copper pipe 1 needs to be strictly cleaned with alkali and water before casting, and the inner wall is rotated and roughened with emery cloth. The 8 gates of the sand box 3 are inserted vertically and fixed respectively by a piece of Ω-shaped chuck 2 with holes fixed by bolts on both sides of the surface;

[0041] (2) Put the dried charcoal powder 5 from the mouth of each copper tube 1 so that its thickness is 20mm;

[0042] 〔3〕The pure aluminum block is heated to 750 ℃ to become pure aluminum liquid 6 and injected into the outer diameter D of the device for preparing copper-clad aluminum core-clad casting billets 2 100mm wall thickness b 2 1mm length H 2 The distance t between the vertical center line of the L-shaped nozzle 4 and the sand box 3 with side holes is 900mm 2 120mm, and then ...

Embodiment 2

[0050] Step 1: Preparation of copper-clad aluminum core-clad casting billet

[0051] 〔1〕The outer diameter D of 28 1 250mm wall thickness b 1 2mm length H 1 The inner wall of the copper pipe 1 with a diameter of 1500mm must be strictly cleaned with alkali and water before casting, and the inner wall shall be roughened by rotation with emery cloth. The 28 gates of the sand box 3 are inserted vertically and fixed respectively by a piece of Ω-shaped chuck 2 with holes fixed by bolts on both sides of the surface;

[0052] (2) Put the dried charcoal powder 5 from the mouth of each copper tube 1 so that its thickness is 30mm;

[0053] 〔3〕The pure aluminum block is heated to 800 ℃ to become pure aluminum liquid 6 and injected into the outer diameter D of the device for preparing copper-clad aluminum core-clad casting billets 2 350mm wall thickness b 2 2mm length H 2 The distance t between the vertical center line of the L-shaped nozzle 4 and the sand box 3 with side holes is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com