Liquid metal electric wire and manufacturing method therefor

A liquid metal and wire technology, applied in the field of wires, can solve the problems of inconvenient placement of electrical appliances, too long and too short wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

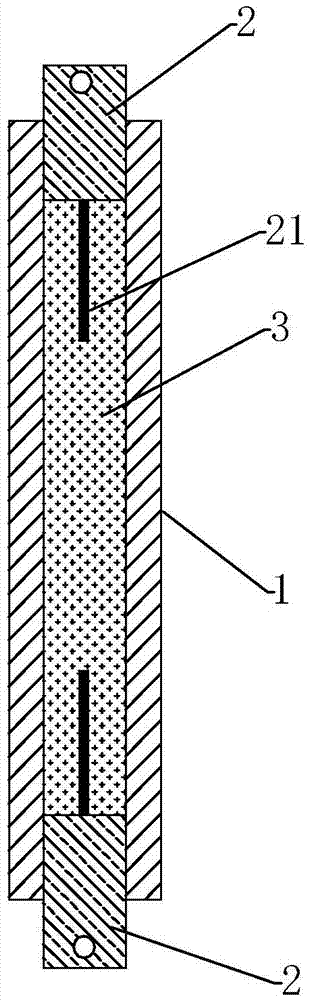

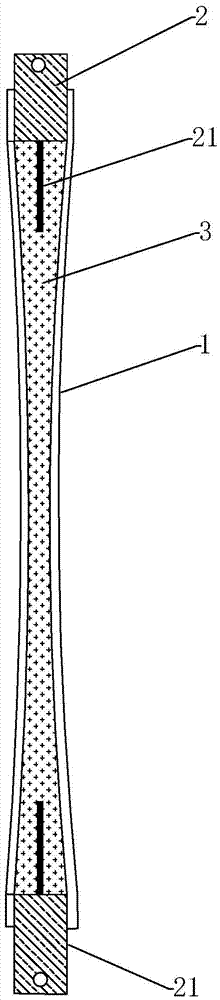

[0019] Such as figure 1 - figure 2 Shown: a liquid metal wire, the liquid metal wire includes an elastic silicone tube (1), the two ends of the elastic silicone tube (1) are fixed with conductive terminals (2), and the tube is filled with liquid conductive metal liquid (3 ), the liquid conductive metal liquid (3) is in contact with the connecting terminal (2) extending into the inner end of the tube, and the conductive connecting terminal (2) at both ends of the elastic silicone tube (1) is generated by using the liquid conductive metal liquid (3) as a conductive medium. Conductive, when in use, when the fixed-length liquid metal wire is too short, the length can be increased by stretching to meet the needs of the application. When the elastic silicone tube (1) is stretched, the diameter of the lumen becomes smaller, and the liquid metal wire The conductive metal liquid 3 will flow to the lumens at both ends due to the pressure of the tube body, and the liquid conductive met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com