Formboard supporting rod

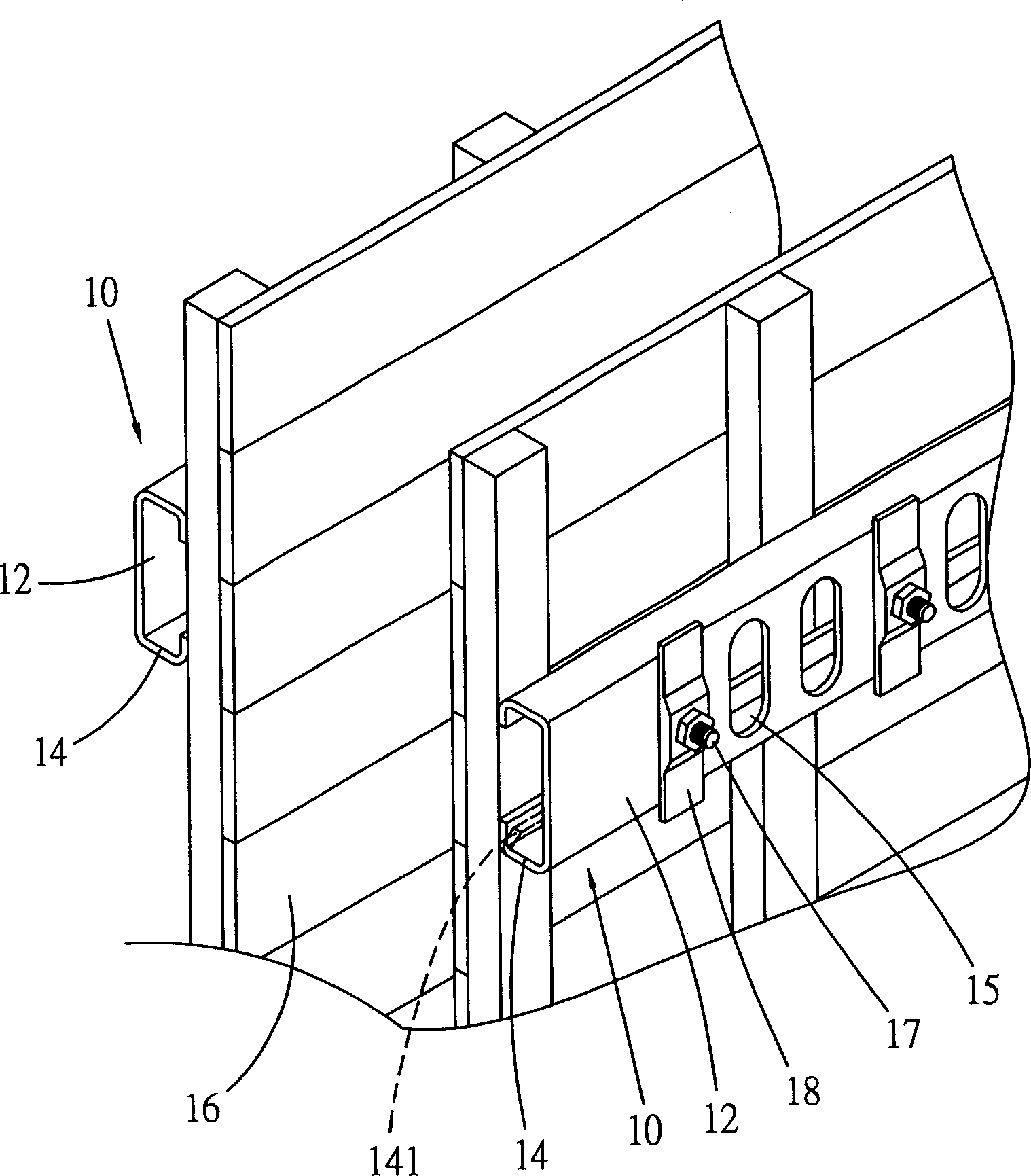

A technology of formwork support and support rods, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of inconvenient installation, insufficient penetration position, and difficult alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

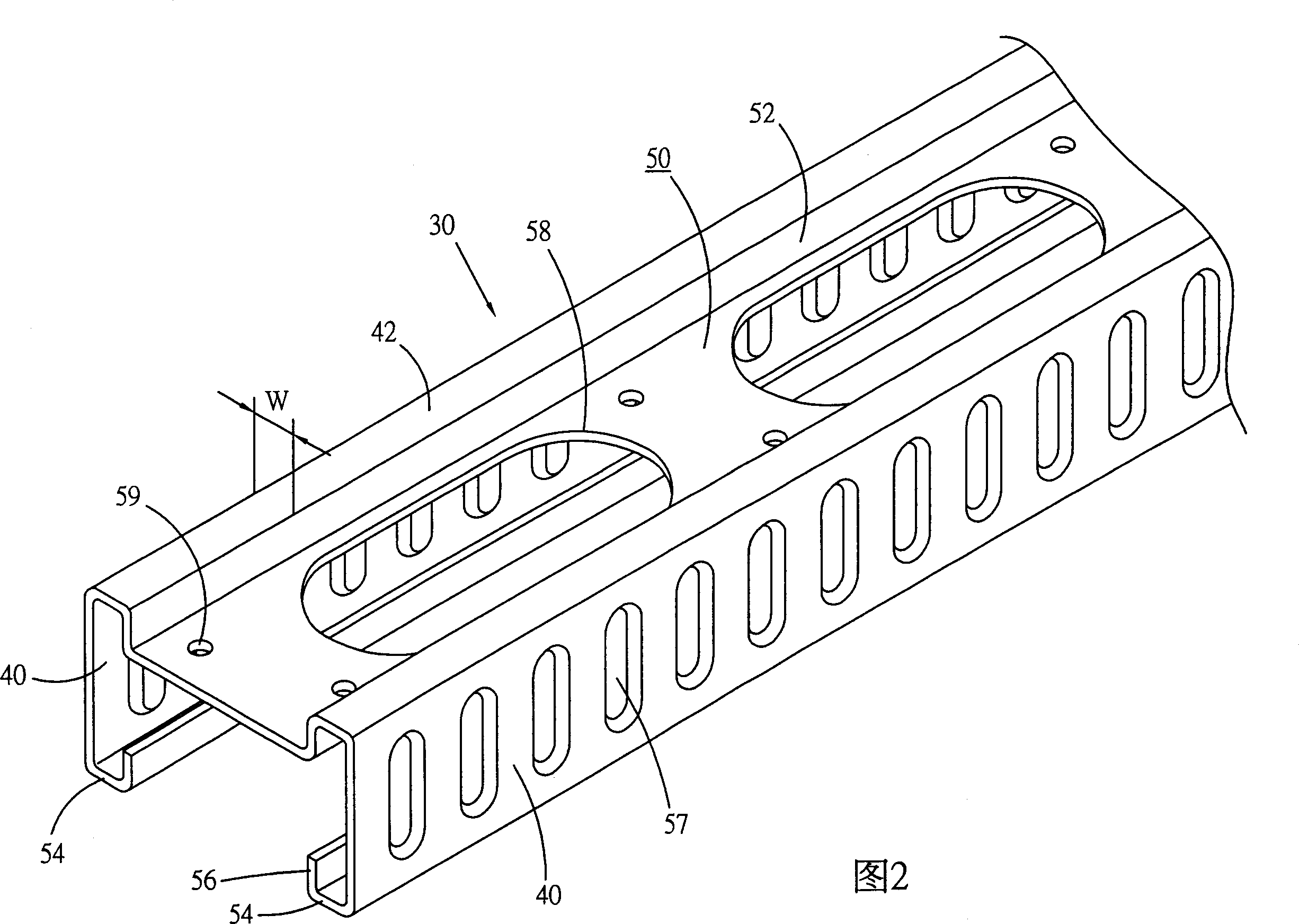

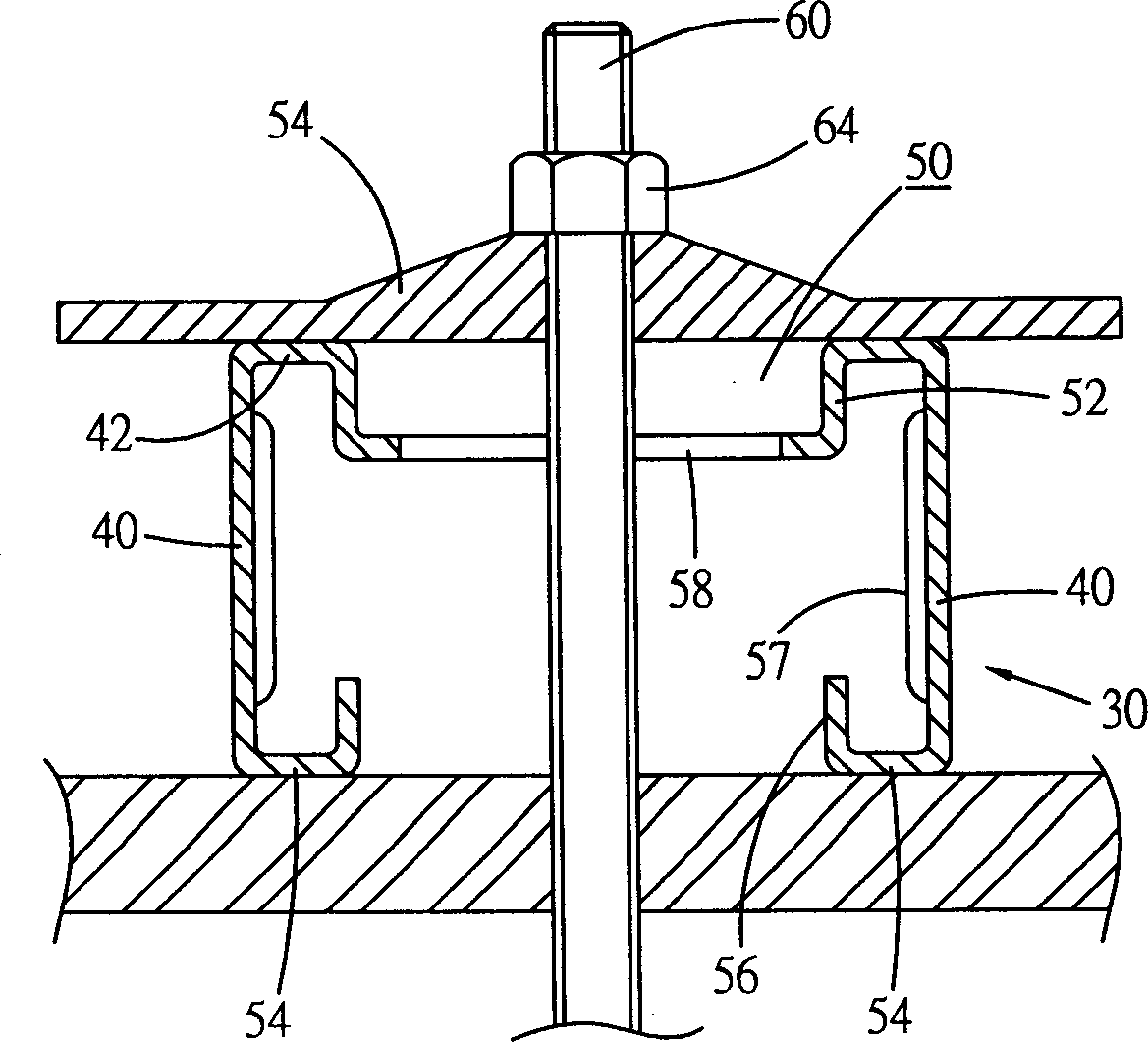

[0025] First please refer to FIG. 2 , which shows a preferred embodiment of the support rod 30 provided by the present invention. The support rod 30 is made of metal, has a single cross-sectional shape, and its cross-sectional structure includes:

[0026] Two upright walls 40 are parallel and keep a proper distance.

[0027] A top wall 42 is located between the two upright walls 40 and is horizontally connected to top edges of the two upright walls.

[0028] A concave space 50 is recessed from the top wall 42 from top to bottom along the axial direction of the support rod. The concave space 50 is located right at the center of the support bar, and two sides of the concave space 50 respectively form an upright small sidewall 52 , and the two small sidewalls 52 maintain a proper distance from the two upright walls 40 .

[0029] The two bottom walls 54 extend horizontally inward from the bottom ends of the two upright walls 40 . Each bottom wall 54 has a free edge and extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com