Telescopic wire rod and preparation method and application thereof

A wire and wire technology, applied in the field of stretchable wire and its preparation, can solve the problems of wire breakage, poor user experience, falling off of solder joints at both ends, etc., and achieve the effects of high stretchability, increased damage, and increased use length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

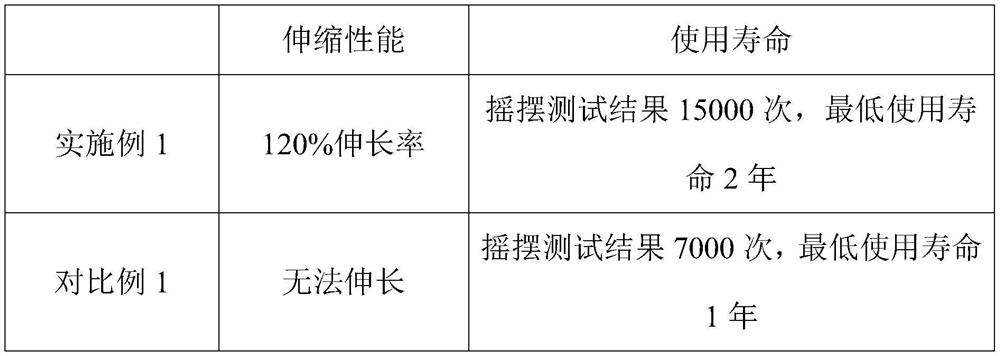

Embodiment 1

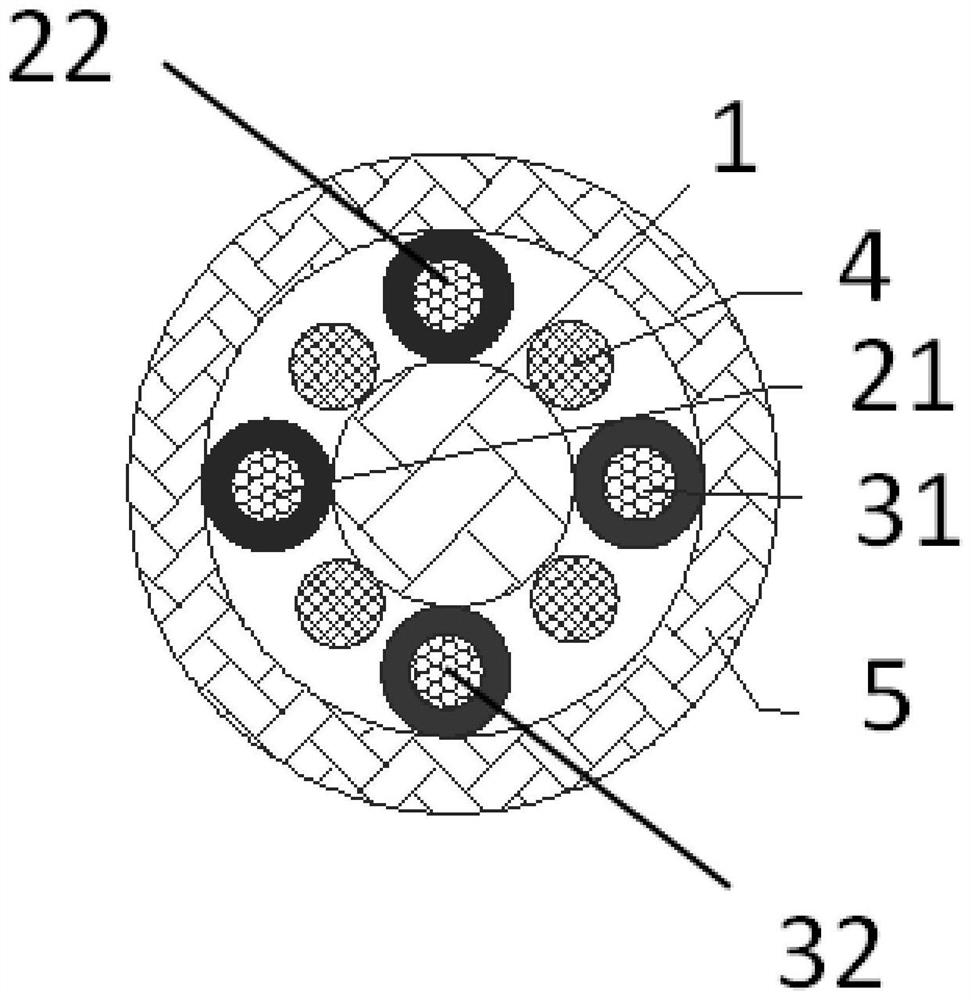

[0093] This embodiment provides a stretchable wire, and its structural schematic diagram is as follows figure 1 As shown, the stretchable wire includes a rubber strip 1, a wire layer and a protective layer 5 from the inside to the outside; the wire layer includes wires and yarns; the wires and the yarns surround the rubber strip; the The protection layer covers the wire layer.

[0094] In this embodiment, the stretchable wire is, for example but not limited to, a charging wire. In some embodiments, the wire includes a power wire and a ground wire, and each of the power wire and the ground wire independently includes the conductor, the nylon wire, and the insulating layer. In some embodiments, the wires include a first power wire 21, a second power wire 22, a first ground wire 31, a second ground wire 32 and four yarns 4;

[0095] Wherein, the first power wire and the first ground wire are arranged oppositely, the second power wire and the second ground wire are arranged oppo...

Embodiment 2

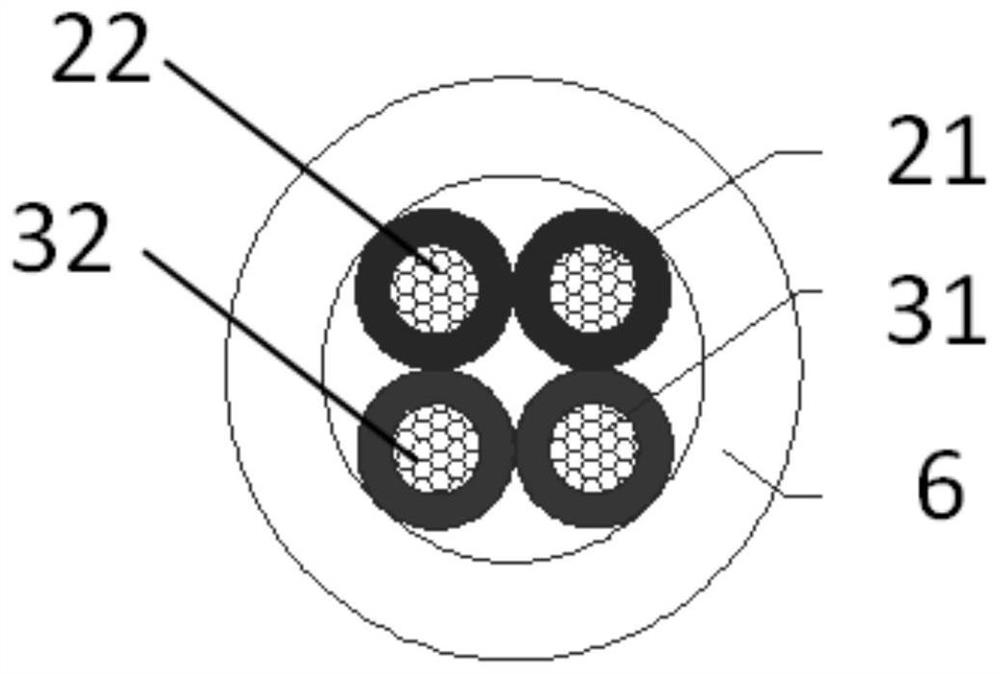

[0112] This embodiment provides a stretchable wire, and the stretchable wire includes a rubber strip, a wire layer and a protective layer from the inside to the outside;

[0113] The wire layer includes a first power wire, a second power wire, a first ground wire, a second ground wire and 6 yarns;

[0114] Wherein, the first power wire and the first ground wire are arranged oppositely, the second power wire and the second ground wire are arranged oppositely, four yarns are arranged between the power wire and the ground wire (2), and the power wire and between the power wires (2 wires) and between the ground wire and the ground wire (2 wires).

[0115] Specifically, the information of each structural component is as follows:

[0116] (1) Rubber strips: 9 high rubber strips with a length × width of 0.4mm × 0.3mm, and twist them to form the center filling of the wire;

[0117] (2) The first power line and the second power line: composed of power wires and an insulating layer co...

Embodiment 3

[0126] This embodiment provides a stretchable wire, and the stretchable wire includes a rubber strip, a wire layer and a protective layer from the inside to the outside;

[0127] The wire layer includes a first power wire, a second power wire, a first ground wire, a second ground wire and 6 yarns;

[0128] Wherein, the first power wire and the first ground wire are arranged oppositely, the second power wire and the second ground wire are arranged oppositely, four yarns are arranged between the power wire and the ground wire (2), and the power wire and between the power wires (2 wires) and between the ground wire and the ground wire (2 wires).

[0129] Specifically, the information of each structural component is as follows:

[0130] (1) Rubber strips: 11 high rubber strips with a length x width of 0.8mm x 0.7mm, which are twisted to form the center filling of the wire;

[0131] (2) The first power line and the second power line: composed of power wires and an insulating laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com