Elastic conductive fiber manufacturing method

An elastic fiber, elastic conductive technology, applied in the field of elastic conductive fiber preparation, can solve the problems of non-recovery, small fracture length, affecting the development of elastic fiber electronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] First, the synthesis of spinnable aligned carbon nanotube arrays.

[0016] Vertically grown carbon nanotube arrays with Fe(1nm) / Al 2 o 3 (10nm) / SiO 2 / Si was synthesized as a catalyst in a tube furnace quartz tube by a typical chemical vapor deposition method. Wherein ethylene (75sccm) is used as carbon source, argon (400sccm) and hydrogen (25sccm) are used as carrier gas. The thickness of the synthesized carbon nanotube array is 250 microns.

[0017] Second, the preparation of elastic conductive fibers.

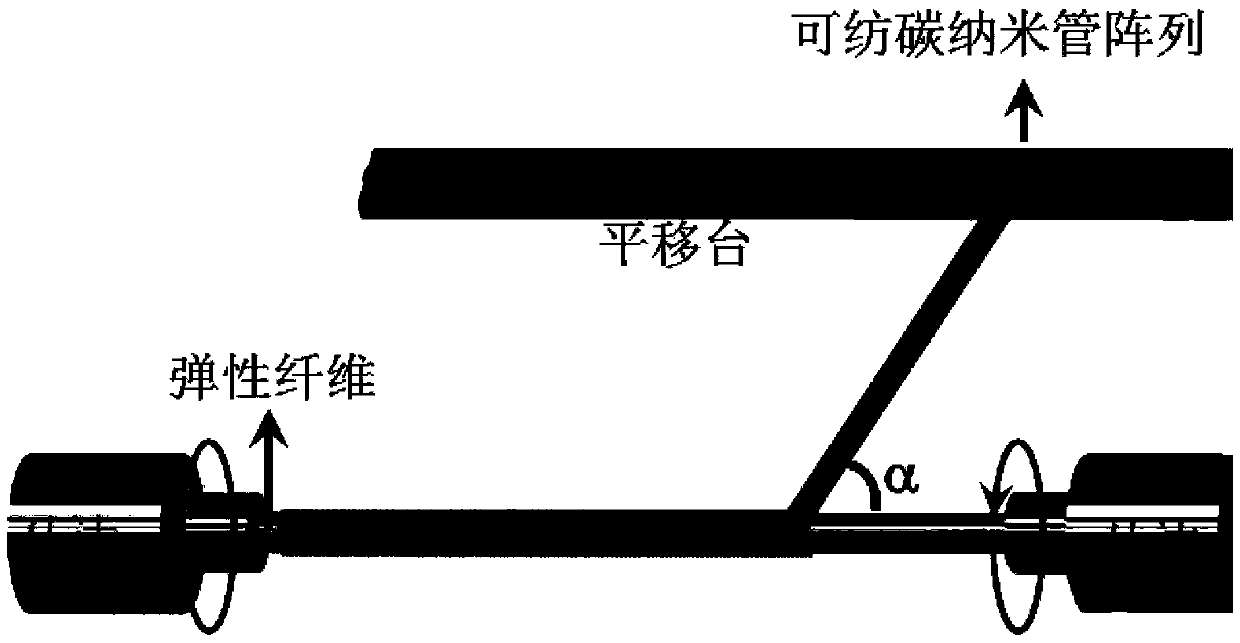

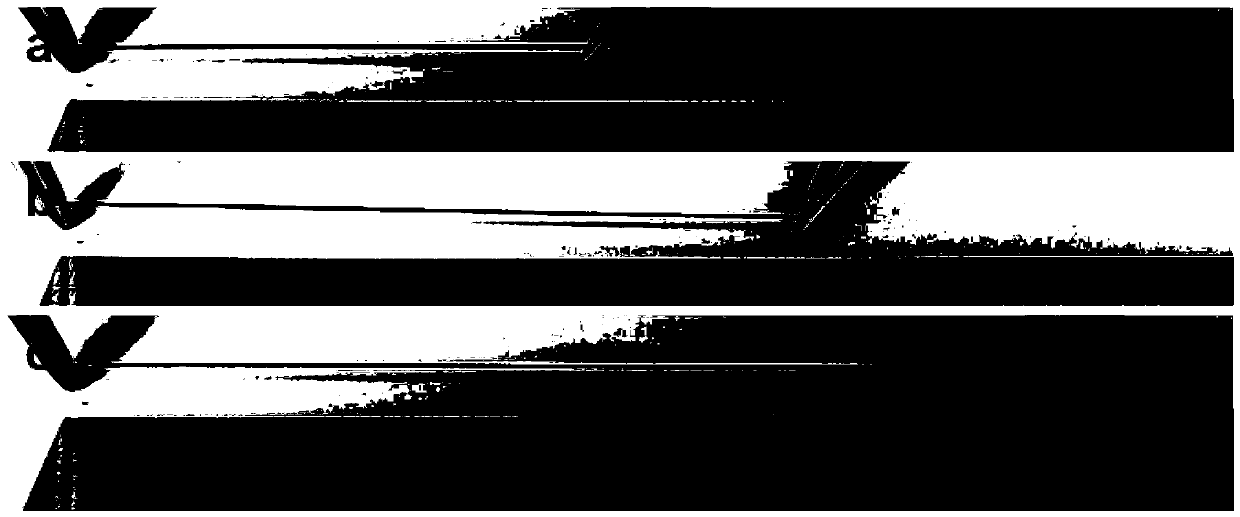

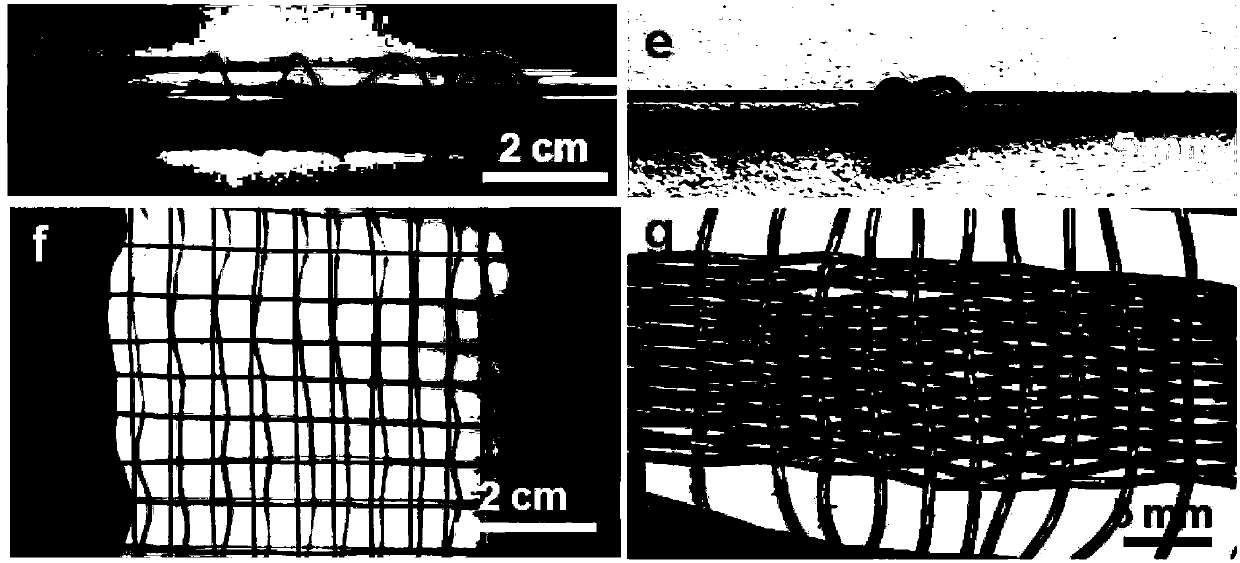

[0018] like figure 1 As shown in the figure, fix the two ends of an elastic fiber on two motors, put a spinnable carbon nanotube array on the translation stage, then pull the carbon nanotube film out of the array, and lay it at a certain angle on elastic fibers. When the two motors and the translation stage are turned on at the same time, the continuous carbon nanotube film will be continuously wrapped on the elastic fiber. By matching the speed of the translat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com