Copper base belt surface treatment device of solar photovoltaic welding belt and processing method thereof

A solar photovoltaic and surface treatment technology, applied in electrical components, climate sustainability, circuits, etc., can solve problems such as defects, and achieve the effects of simple and practical structure, increased performance, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

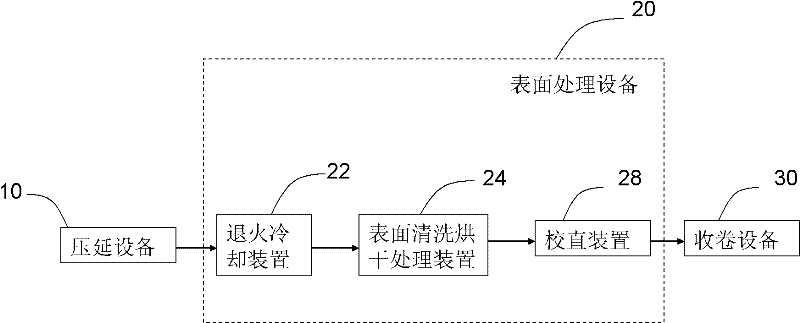

[0050] Such as figure 1 As shown, a copper base strip surface treatment equipment for solar photovoltaic welding strips of the present invention is installed after the rolling equipment 10 and before the winding equipment 30 in the solar photovoltaic welding strip production line, including: annealing cooling device 22, copper base strip 5 After being rolled out from the calendering equipment 10, enter the annealing cooling device 22 for annealing and cooling; the surface cleaning and drying treatment device 24, the annealed and cooled copper base strip enters the surface cleaning and drying treatment device 24, and cleans the copper base strip 5 surface and drying; and a straightening device 28, the copper base strip after cleaning and drying enters the straightening device 28 to improve straightness.

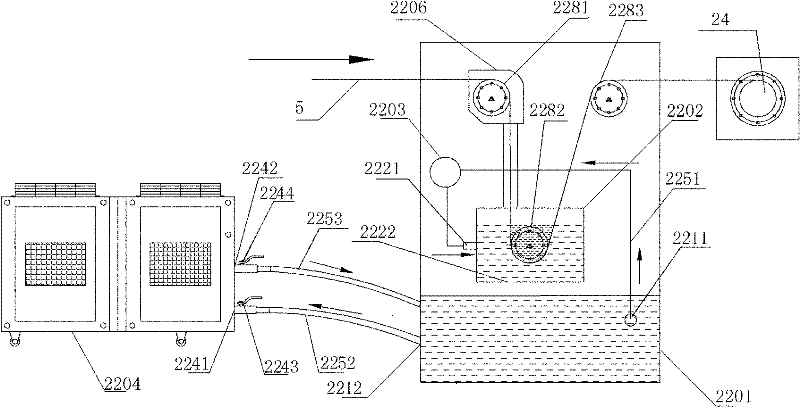

[0051] Such as figure 2 As shown, in the copper-based strip surface treatment equipment of a solar photovoltaic ribbon of the present invention, the annealing cooling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com