Heat pump control method for dehumidification and drying

A control method and heat pump technology, applied in drying, heat pump, dryer, etc., can solve the problem of low temperature dehumidification of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

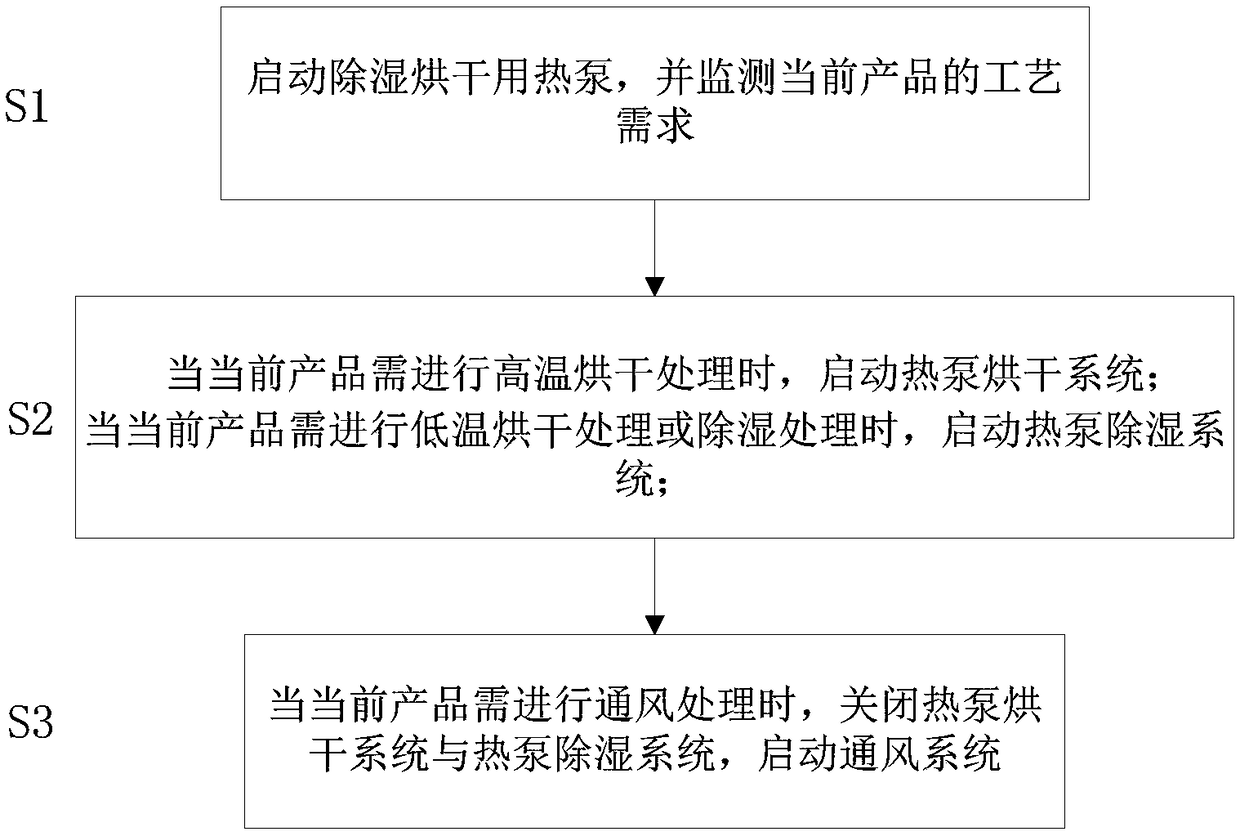

[0221] The control in this embodiment provides switching between the three modes of the product: baking mode, dehumidification mode and ventilation mode;

[0222] The closed refrigerant heat exchange circuit that constitutes the baking mode is composed of compressors, four-way valves, air supply heating condensers, liquid receivers, outdoor evaporators, four-way valves, and vapor-liquid separators connected in sequence.

[0223] The closed refrigerant heat exchange circuit that constitutes the dehumidification mode is composed of a compressor, a four-way valve, a supply air heating condenser, a liquid receiver, a return air evaporator, a four-way valve, and a vapor-liquid separator connected in sequence.

[0224] The hot air supply channel that constitutes the baking mode or dehumidification mode is composed of a supply air heating condenser, a supply fan, and a drying room connected by pipelines in sequence.

[0225] Set the return air setting after the air supply to cooperat...

Embodiment 2

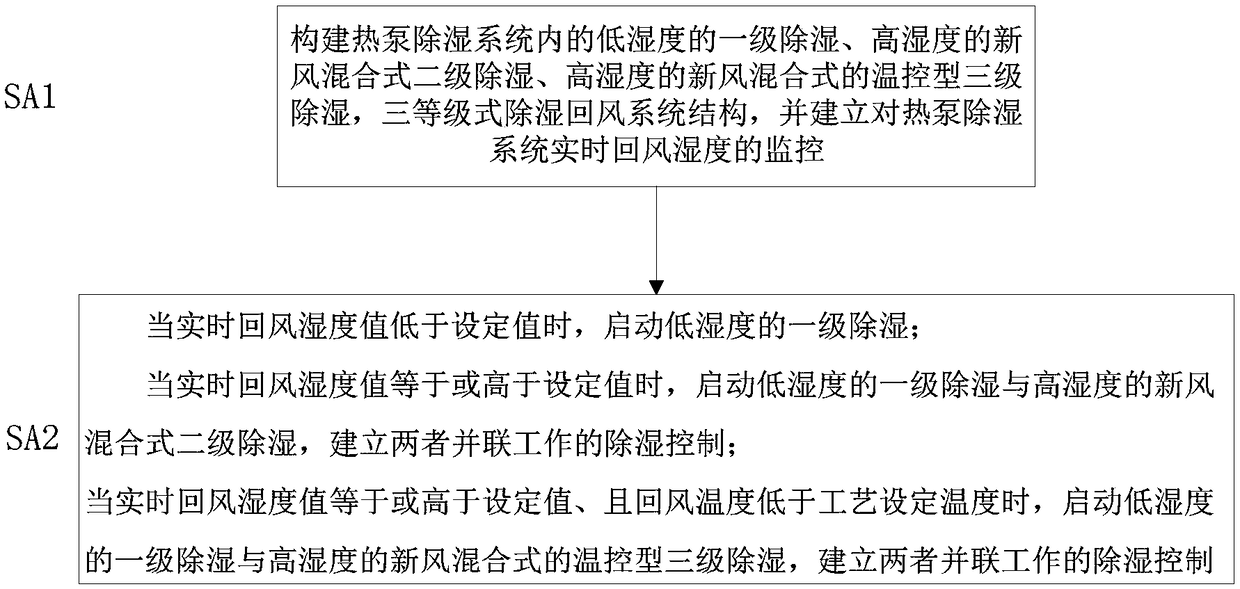

[0230] The control in this embodiment is based on the dehumidification mode, and further establishes three levels of dehumidification control in the dehumidification mode according to the humidity of the return air, which are: Ⅰ. Low humidity level 1 dehumidification; Ⅱ. High humidity fresh air Hybrid two-stage dehumidification; Ⅲ. High-humidity fresh air hybrid temperature-controlled three-stage dehumidification.

[0231] When the humidity of the return air is lower than the set value of the process, the low-humidity first-stage dehumidification is started, and the closed-type dehumidification composed of the drying room, the first primary filter, the return air evaporator, and the supply air heating condenser connected by pipelines in sequence Circulation loop, forming a return air dehumidification channel for primary dehumidification;

[0232] When the humidity of the return air is higher than the set value of the process, the high-temperature fresh air mixed-type secondary...

Embodiment 3

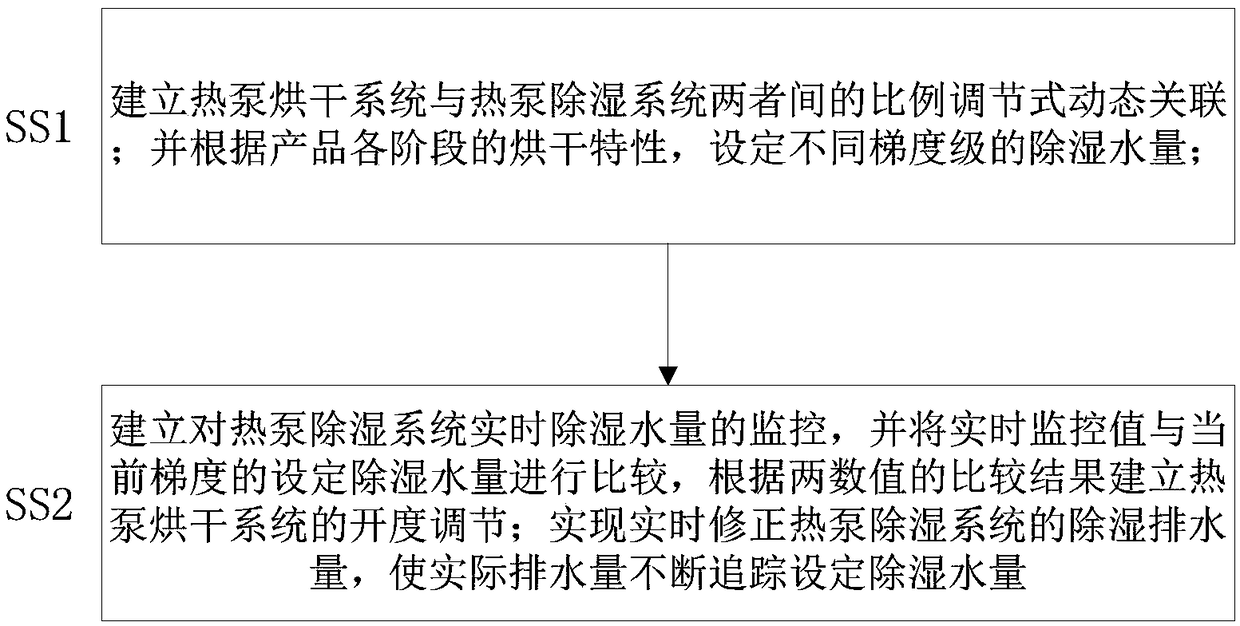

[0235] The control in this embodiment is based on the dehumidification mode, and further establishes a closed-loop adaptive dynamic dehumidification adjustment control system based on the baking mode and dehumidification mode according to the dehumidification displacement;

[0236] The baking mode is composed of a first heating unit and an air supply unit;

[0237] The dehumidification mode is composed of a second heating unit, an air supply unit and a return air dehumidification unit;

[0238] According to the dehumidification and drainage volume, a closed-loop self-adaptive dynamic dehumidification adjustment control system composed of the ratio adjustment between the first heating unit and the second heating unit is established;

[0239] The first heating unit is composed of a sequentially connected compressor, four-way valve, air supply heating condenser, liquid receiver, outdoor evaporator, four-way valve, and vapor-liquid separator;

[0240] The second heating unit is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com