Method for drying through temperature sensor of roller washing machine

A drum washing machine and temperature sensor technology, which is applied to household dryers, washing devices, textiles and papermaking, etc., can solve the problems of inability to adjust dynamically, frequent relay actions, constant heating temperature, etc., to achieve less frequent actions, easier judgment, Accurately judge the effect of judging methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

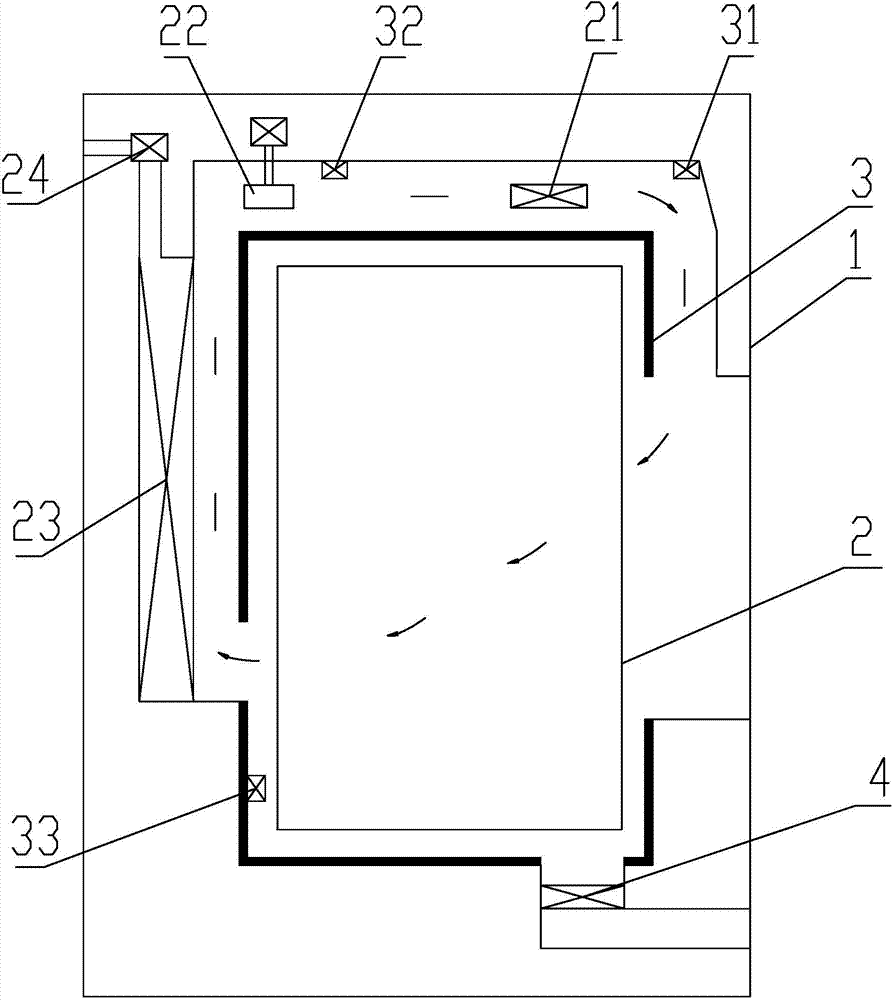

[0033] Such as Figure 1 to Figure 3 as shown,

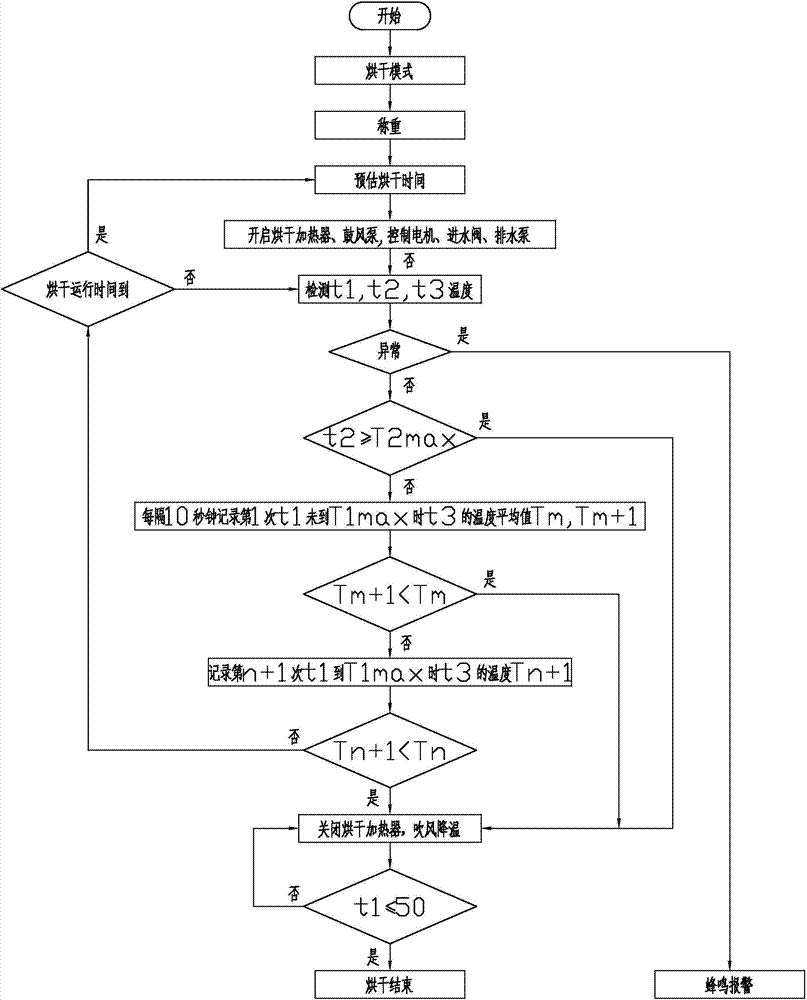

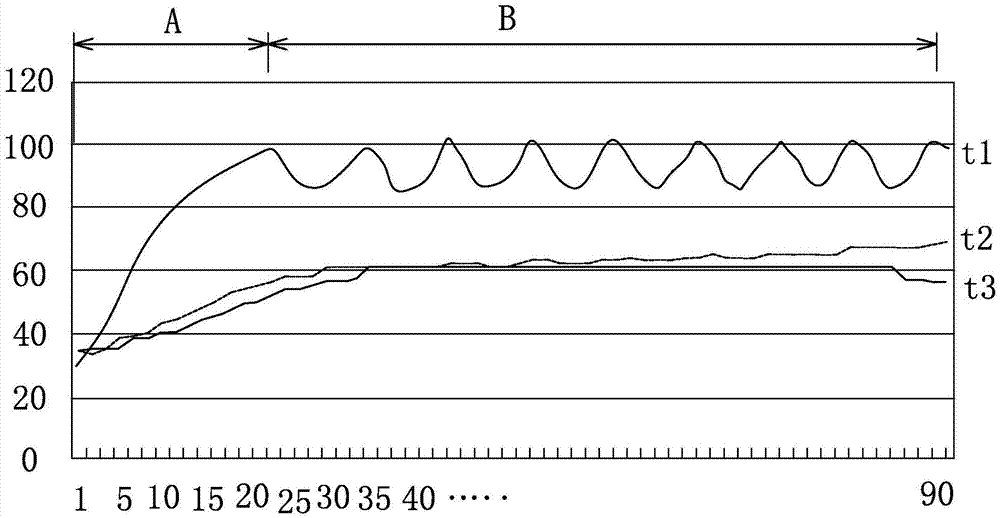

[0034] The invention discloses a drying control method for a full-automatic drum washing machine through temperature sensing. It is mainly a judgment method based on three temperature sensors. It is TSDM, namely three sensor dry method).

[0035] The internal structure of the drum washing machine. The main body of the washing machine has a washing drum, a clothes bucket, a drain pump, a water inlet valve and other related accessories, and a hot air circulation duct is arranged inside the main body of the washing machine.

[0036] A circulating air duct is arranged on the top of the washing machine body, and the circulating air duct communicates with the front end and the rear end of the cavity of the washing tub forwardly and backwardly to form a passage.

[0037] A condenser, a blower pump and a heater are arranged sequentially from back to front in the circulating air duct. The condenser includes a cold water pipe and a noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com