A BFG Boiler Negative Pressure Optimization Control Method

A technology of optimized control and furnace negative pressure, applied in the direction of combustion control, combustion method, lighting and heating equipment, etc., can solve the unfavorable safe and stable operation of main boiler equipment, accelerate the damage of induced draft fan, shorten the service life of desuperheating water control valve and other problems, to achieve the effect of reducing frequent actions, improving operation stability, and suppressing negative pressure internal disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

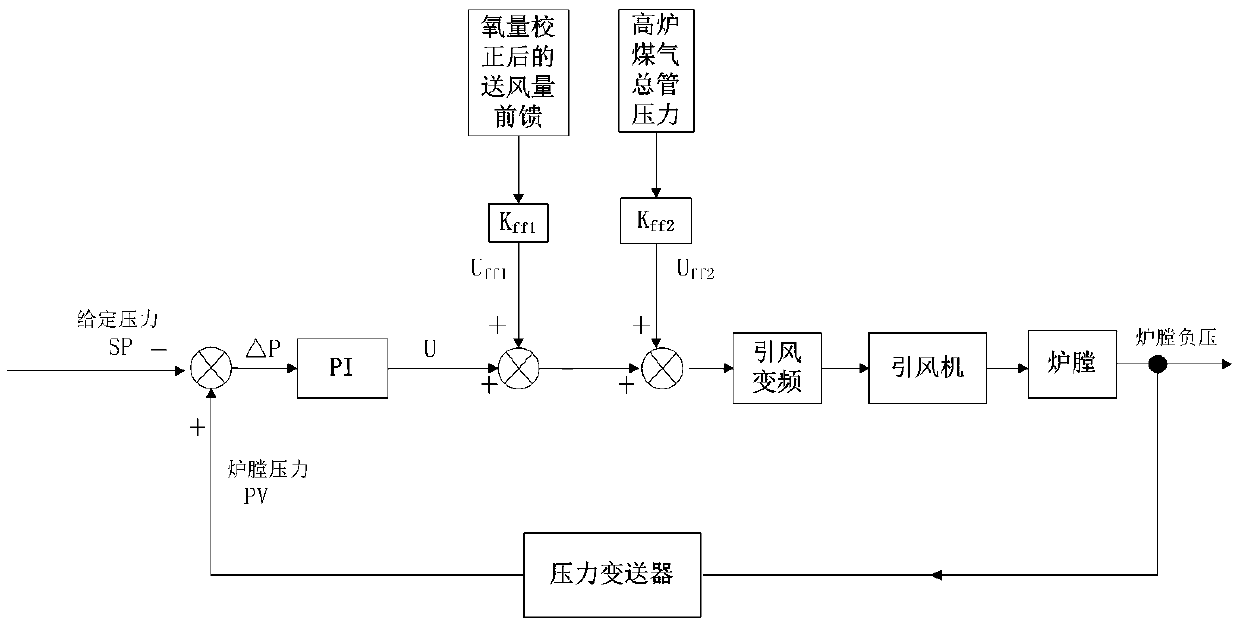

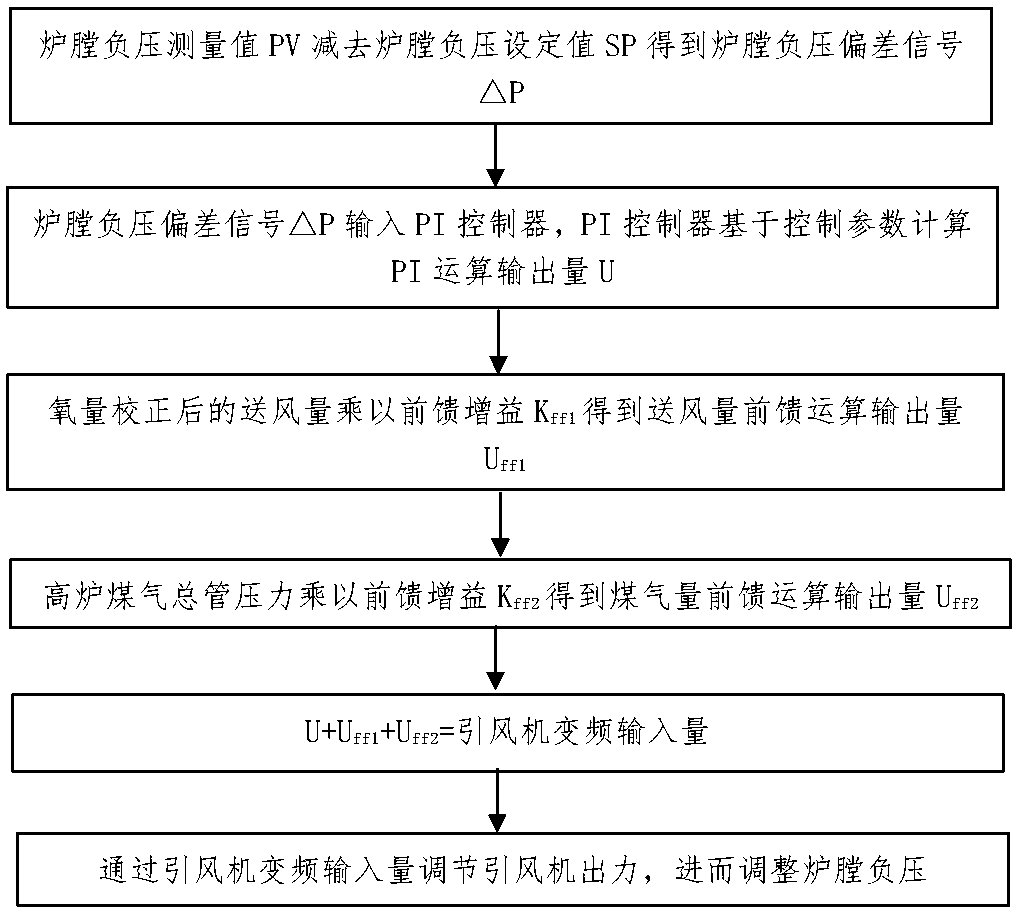

[0024] The present invention is described in further detail now in conjunction with accompanying drawing.

[0025] The feed-forward control method of the present invention to quickly eliminate the dynamic deviation of unit furnace negative pressure can be directly implemented in various distributed control systems DCS through configuration methods. Successfully applied on the unit.

[0026] Before adopting the present invention, the furnace pressure of the unit fluctuated between (-173~170) Pa during most of the running time, and could not stabilize and converge. However, after adopting the present invention, the fluctuation of the furnace pressure can be controlled within the safe range of (-80Pa~5.9Pa), which effectively suppresses the sporadic interference of the blast furnace gas disturbance source, improves the control accuracy of the furnace pressure, and suppresses the influence on the overheated air temperature. The control disturbance slows down the action frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com