Vertical oven for circuit board and drying method thereof

A circuit board and vertical technology, applied in the field of circuit board drying equipment, can solve the problems of large occupied area and poor drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

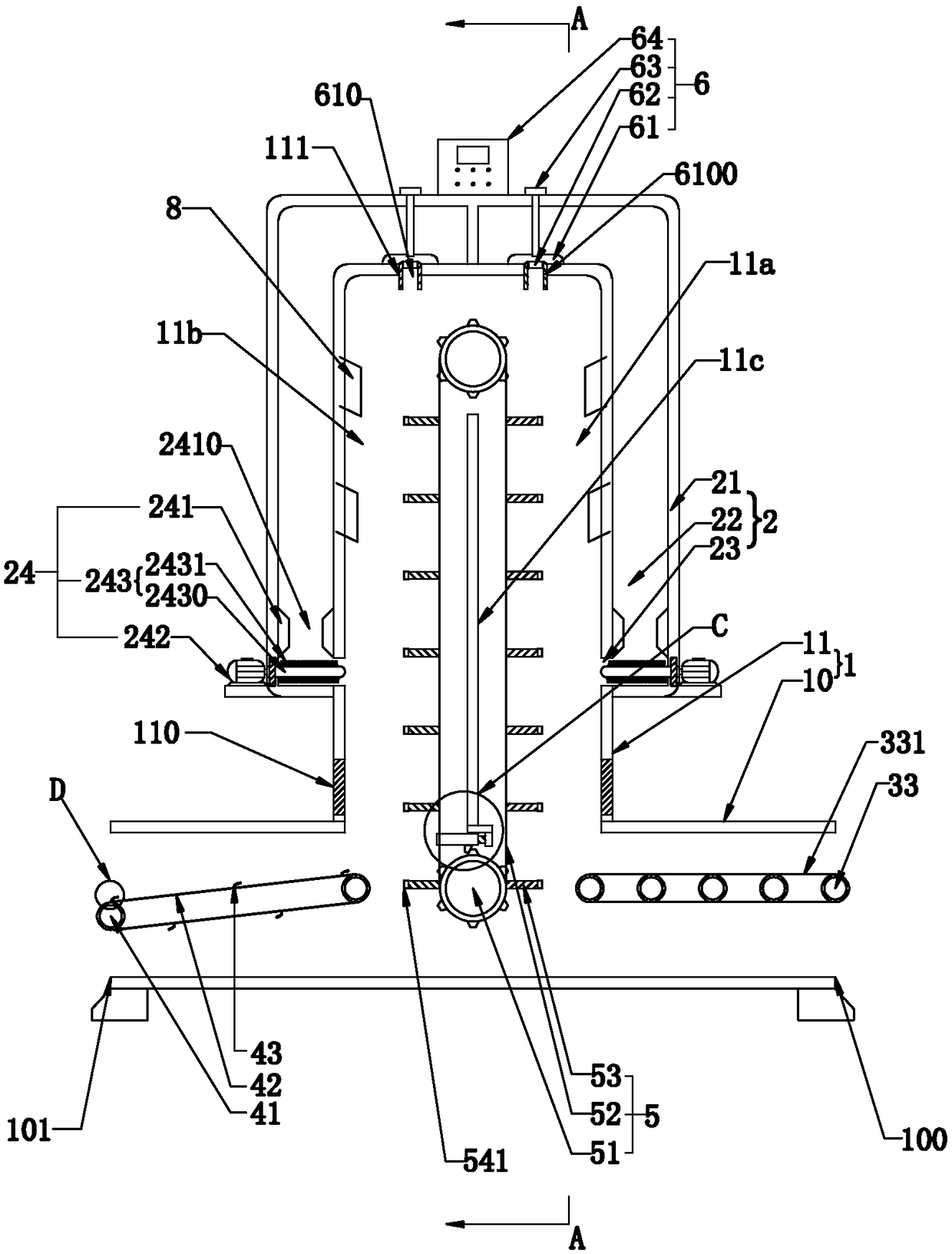

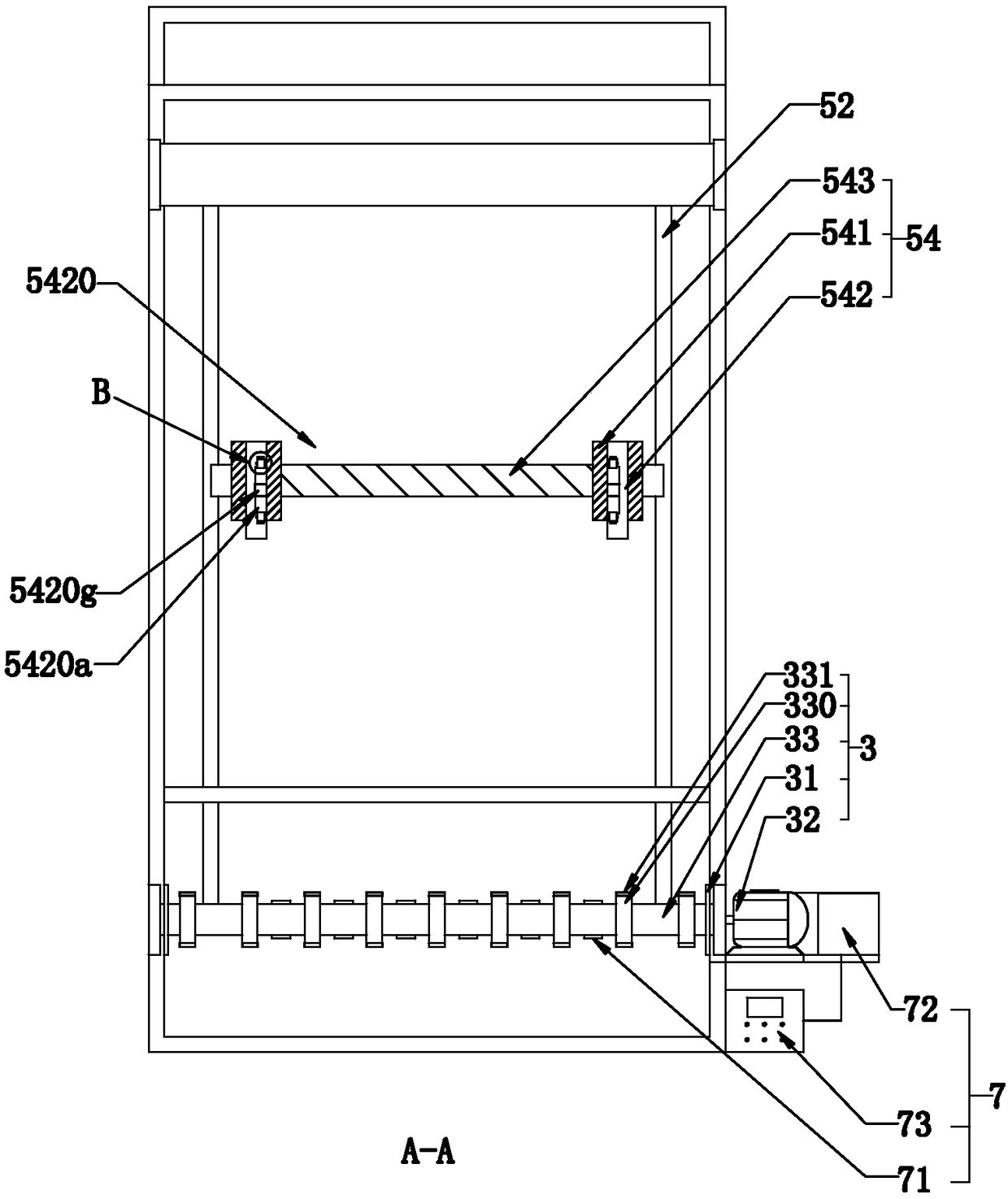

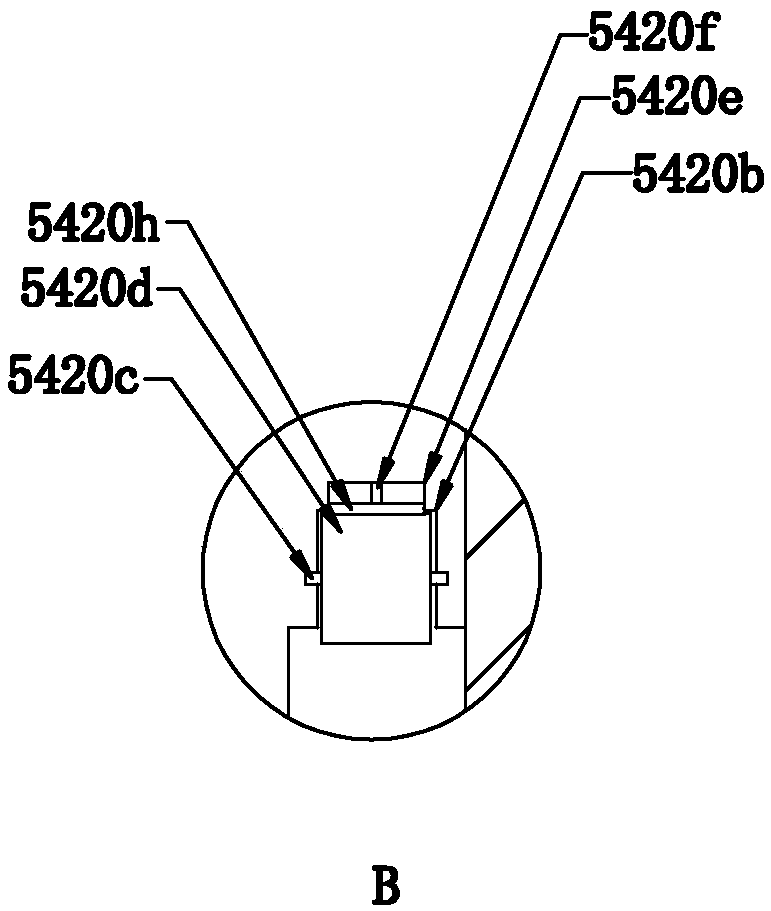

[0034] Such as Figure 1 to Figure 7 As shown, the present invention discloses a vertical oven for circuit boards. In a specific embodiment of the present invention, it includes a main box body 10 and a heating box body 11 vertically connected to the middle part of the top end surface of the main box body 10. The vertical box body 1 in the shape of "丄", the heat preservation assembly 2 arranged on the outer wall of the heating box body 11, the inlet 100 and the outlet 101 respectively arranged at both ends of the main box body 10, and the inlet 100 and the outlet 101 respectively The input assembly 3 and the output assembly 4 used to transport the circuit board are located inside the heating box 11 and are used to transport the circuit board frame on the input assembly 3 to the top of the heating box 11 for one week and then The lifting assembly 5 that transports the circuit board frame to the output assembly 4; the outer walls on both sides of the intersection between the hea...

Embodiment 2

[0047] A method for drying a circuit board in a vertical oven, characterized in that it comprises the following steps:

[0048] S1: Place the circuit board frame with the circuit board on the input assembly located at the entrance of the main box, and transport it to the inside of the heating box through the input assembly;

[0049] S2: The lifting component receives the circuit board frame on the input component through the clamping device and transports the received circuit board frame to the top of the heating box. After passing the top of the heating box, the circuit board frame is placed on the main box delivery of output components at the outlet of the body;

[0050] S3: When the clamping device holding the circuit board frame moves to the output assembly, the part of the circuit board can be separated from the clamping device by pushing the component, and the part of the circuit board can be pushed to the output assembly;

[0051] S4: The heated circuit board frame is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com