Chemical raw material drying device

A technology for drying equipment and chemical raw materials, which is applied in drying, drying machines, drying of granular materials, etc. It can solve the problems of poor air permeability and unevenness of material particles, and large space for drying drums, so as to increase air permeability and facilitate Even contact and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

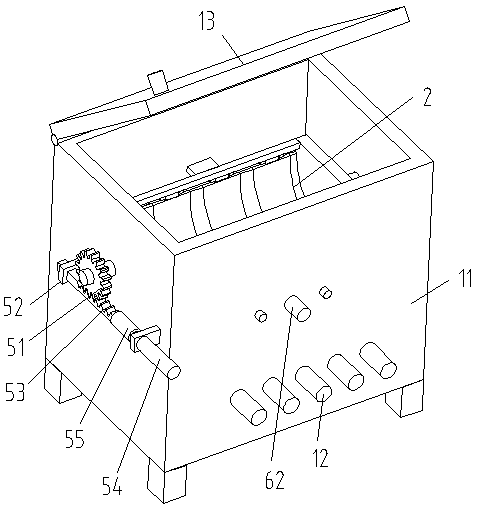

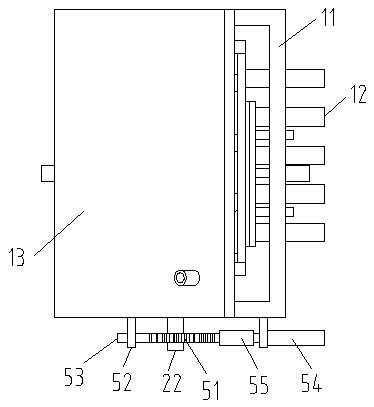

[0026] Such as Figure 1-7 and Figure 10 As shown, a chemical raw material drying device provided by the present invention includes a box body 11, and a group of air delivery pipes 12 are fixedly connected to the bottom of the box body 11. The air delivery pipes 12 are used to input dry hot air into the box body 11. On the box body 11 The side is hingedly connected to the sealing cover 13, which can be opened when needed. The upper side of the sealing cover 13 is provided with an exhaust pipe connected to the inner cavity of the box body 11. The inside of the box body 11 is rotatably connected to the distribution box 2. The distribution box 2 includes an upper frame 21 , the upper frame 21 is a square frame, and the opposite sides of the upper frame 21 are respectively fixedly connected to the rotating shaft 22, and the rotating shaft 22 is respectively connected to the inner wall of the corresponding box body 11 in rotation, and one of the rotating shafts 22 extends out of t...

Embodiment 2

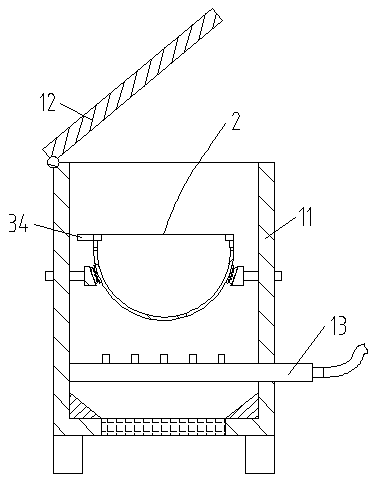

[0028] Such as Figure 3-6 As shown, on the basis of Embodiment 1, the inside of the box body 11 is rotated and connected to the sieve plate 31, the sieve plate 31 is uniformly provided with vent holes, the aperture of the vent hole is smaller than the particle diameter of the chemical raw material particles to be dried, and the inner wall of the box body 11 is fixedly connected. Support plate 32, support plate 32 is fixedly connected with support spring 33 at one end of the upper side of sieve plate 31, one side of material distribution box 2 is fixedly connected with horizontal plate 34, and the inner wall of box body 11 is fixedly connected with support plate 35, and support plate 35 is provided with a sliding hole , vertically slidingly connect the square vertical bar 36 in the sliding hole, the upper end of the square vertical bar 36 is fixedly connected to the baffle plate 37, and the first spring 38 is fixedly connected between the baffle plate 37 and the support plate 3...

Embodiment 3

[0031] Such as figure 1 , image 3 and Figure 7-10 As shown, on the basis of Embodiment 2, the bottom of the curved plate 24 is fixedly connected to the wave plate 61 at one end close to the hook spring 25, and the outer side of the box body 11 is fixedly connected to the first cylinder 62, and the telescopic rod of the first cylinder 62 extends into the box body 11 inside and fixedly connected to the stopper 63 at the end, the side of the stopper 63 close to the arc plate 24 is arranged in an arc shape, the side of the stopper 63 close to the arc plate 24 is fixedly connected to the rubber block 64, and the rubber block 64 is close to the arc One side of the shape plate 24 is arranged in a wave shape, and the rubber block 64 is arranged corresponding to the wave plate 61 and the wave surface of the two is suitable. There is a guide hole, and the guide rod 65 passes through the guide hole and is slidably connected. During the periodical swing of the material distribution box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com