Device for drying bulk material in at least one storage container

A technology for storing containers and loose materials. It is used in drying solid materials, drying gas arrangements, and dryers for static materials. It can solve the problems of expensive equipment parts and huge space, and achieve the best dehumidification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

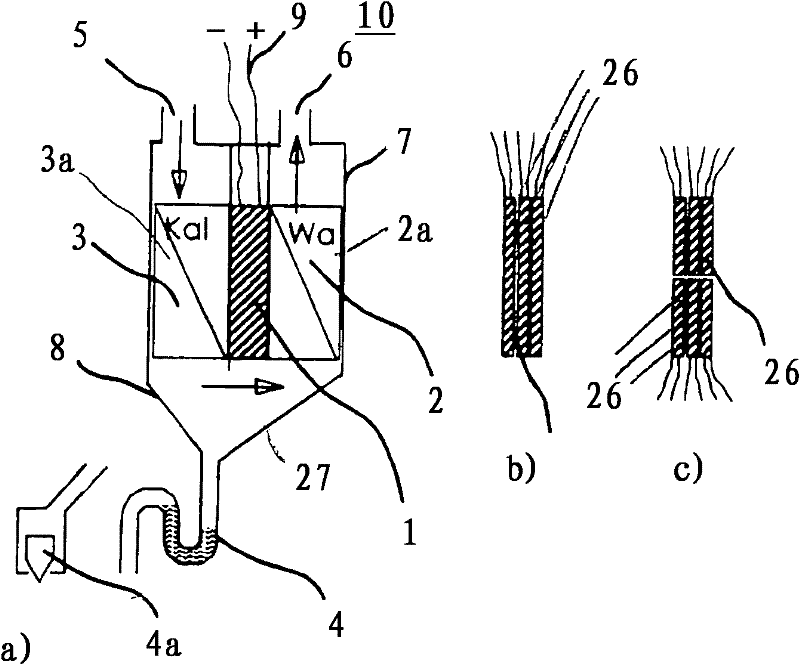

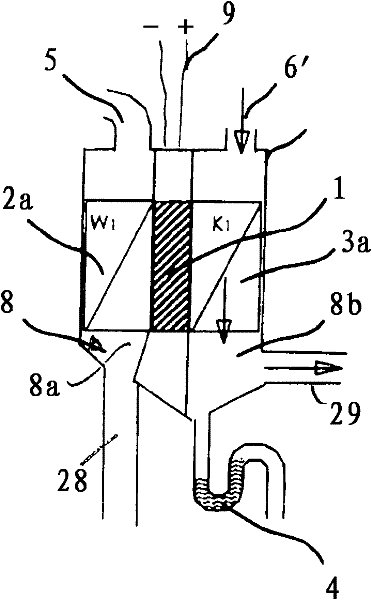

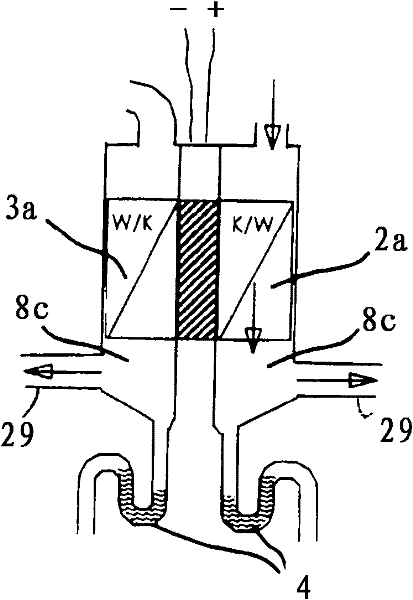

[0026] with the help of Figures 1 to 3 Explain the principle of the device for drying bulk materials according to the invention. The bulk material is dried using a dehumidification unit 10 which has at least one Peltier element. The dehumidification unit 10 has a housing 7 which is divided into two flow chambers 2 , 3 by a partition wall 1 . The partition wall 1 is provided with at least one Peltier element 26 . Such as figure 1 As shown in b and 1c, it can be connected ( figure 1 b) can also be consecutive and side by side ( figure 1 c) A plurality of Peltier elements 26 are arranged. Using several Peltier elements 26 can increase the temperature difference.

[0027] The characteristic of a Peltier element is that when an electric current is applied, one plane is heated and the other side is cooled.

[0028] exist figure 1 In the embodiment shown in a, the cold side of the Peltier element 26 is located in the flow chamber 3 and the hot side is located in the flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com