Method for recycling valuable metal from silver electrolysis mother liquor copper deposition drags

A technology of valuable metals and copper slag, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high anti-corrosion requirements, low metal recovery rate, high production cost, etc., and achieve significant economic benefits and metal recovery. The effect of high efficiency and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

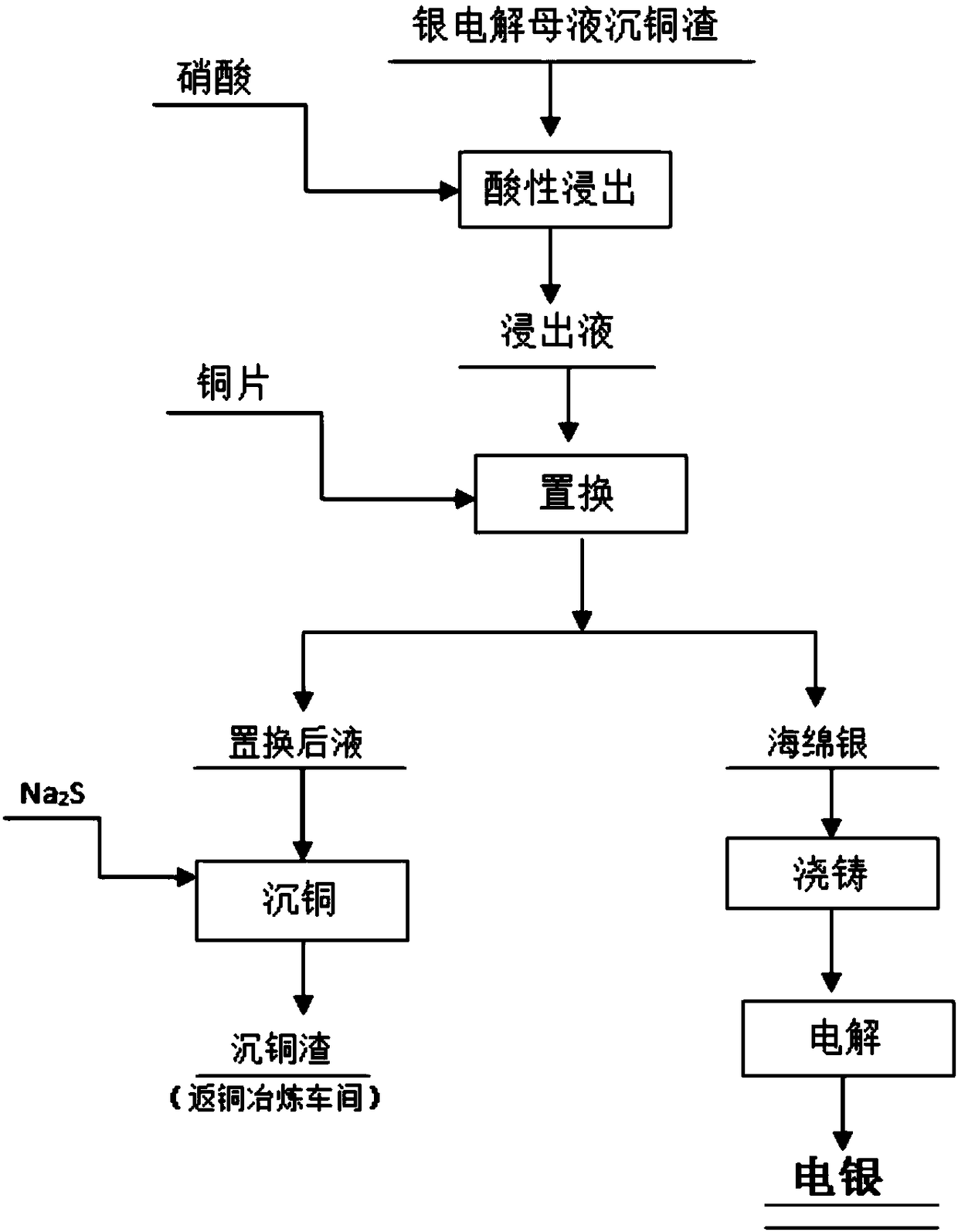

Embodiment 1

[0019] Take by weighing 200g silver electrolysis mother liquor copper precipitation slag (wherein containing Pb0.61%, Bi0.51%, Ag15.13%, Cu35.02%) and put into beaker, adding concentration is that the nitric acid of 85g / L carries out leaching, and control nitric acid and The liquid-solid ratio of the copper precipitation slag is 5:1, the temperature is 30°C, the stirring speed is 600r / min, and the reaction is carried out for 45 minutes under constant stirring. After the copper precipitation slag is completely dissolved, the leaching solution is obtained. After washing, insert it into the leaching solution for silver replacement, filter and separate after replacement for 1 hour to obtain sponge silver powder and replacement solution, and add enough Na to the replacement solution 2 S to deposit valuable metals such as copper, bismuth and lead, and filter to obtain metal slag, and then return the obtained metal slag to the smelting system to recover copper, bismuth and lead, the c...

Embodiment 2

[0021] Take by weighing 200g silver electrolysis mother liquor copper precipitation slag (wherein containing Pb0.44%, Bi0.36%, Ag13.22%, Cu32.17%) and put into beaker, add the nitric acid that concentration is 75g / L and carry out leaching, control nitric acid and The liquid-solid ratio of the copper precipitation slag is 6:1, the temperature is 60°C, the stirring speed is 500r / min, and the reaction is continued for 30 minutes under constant stirring. After the copper precipitation slag is completely dissolved, adjust the pH to 0.5, clean the copper sheet and insert it into the leach solution Replace silver in the medium, filter and separate after replacing for 2 hours, obtain sponge silver powder and replacement liquid, add enough Na to the replacement liquid 2 S deposits valuable metals such as copper, bismuth, lead, etc., filters to obtain metal slag, and then returns the obtained metal slag to the smelting system to recover copper, bismuth and lead, the contents of which are...

Embodiment 3

[0023] Take by weighing 200g silver electrolysis mother liquor copper precipitation slag (wherein containing Pb0.57%, Bi0.49%, Ag14.64%, Cu34.16%) and put into beaker, add the nitric acid that concentration is 110g / L and carry out leaching, control nitric acid and The liquid-solid ratio of the copper precipitation slag is 4:1, the temperature is 85°C, the stirring speed is 700r / min, and the reaction is continued for 60 minutes under constant stirring. After the copper precipitation slag is completely dissolved, adjust the pH to 1.5, clean the copper sheet and insert it into the leaching solution Replace silver in the medium, filter and separate after 4 hours to obtain sponge silver powder and replacement liquid, add enough Na to the replacement liquid 2 S to deposit valuable metals such as copper, bismuth, lead, etc., filter to obtain metal slag, and then return the obtained metal slag to the smelting system to recover copper, bismuth and lead, the contents are respectively Cu3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com