Bamboo filament decoration panel capable of adjusting humidity and preparation method and application thereof

A decorative panel and bamboo silk technology, which can be applied in applications, home decoration, and other household appliances, etc., can solve the problems of ordinary glue degree and performance, poor three-dimensional effect, and low production efficiency, and achieve a wide range of applications and fields, and production High efficiency and quality controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In addition, the embodiment of the present invention also provides a method for preparing the above-mentioned adjustable humidity bamboo silk decorative panel, for example, it may include the following steps: soak the straw paper in the first glue, place the soaked straw paper on the solid wood strip A slab is obtained between the composite board layer and the bamboo silk decorative layer; then the slab is pressed, and the pressure relief and health preservation are carried out in sequence.

[0045] The solid wood strip composite ply can be evenly coated with isocyanate adhesive on the left and right contact surfaces of the solid wood strip, and the glue amount is 55-65g / m 2 . Then splicing is carried out, and the splicing can be spliced and finalized for 2.5-3.5 hours under the condition of a pressure of 0.7-0.9MPa. After the adhesive in the base material of the solid wood panel is cured, the surface is sanded to ensure that the surface of the panel is flat and ther...

Embodiment 1

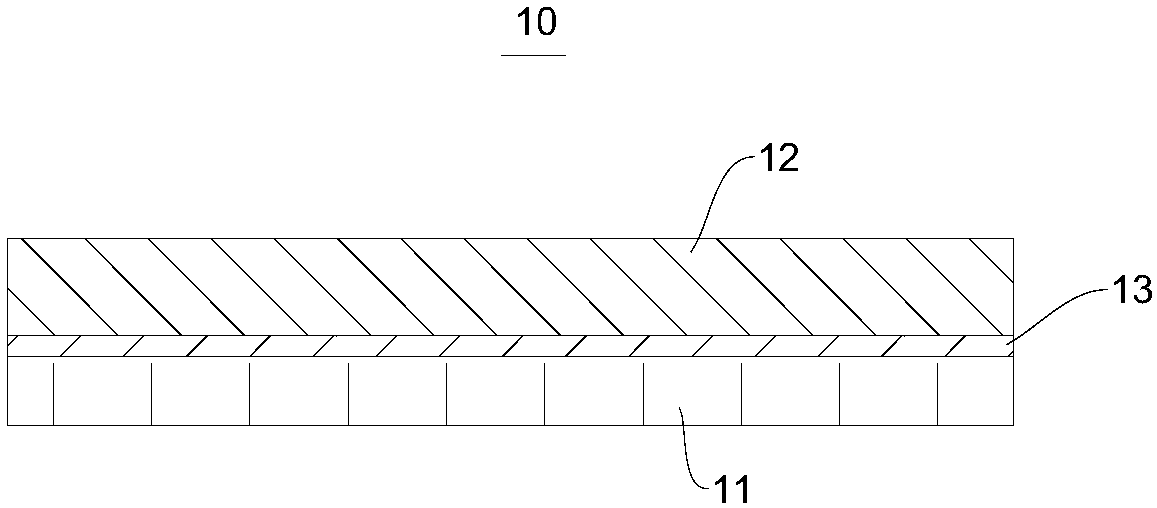

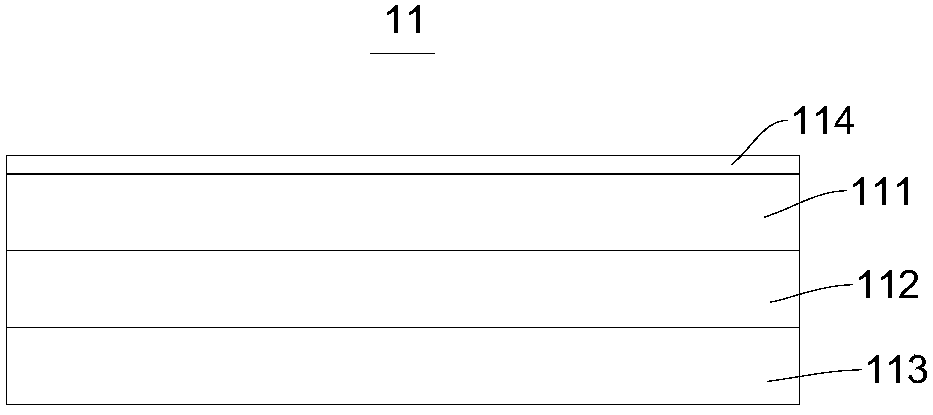

[0054] Please refer to figure 1 The humidity-adjustable bamboo silk decorative panel 10 provided in this embodiment includes a layer of solid wood strip composite board layer 11, a layer of bamboo silk decorative layer 12 and a straw woven paper layer 13 with a thickness of 1 mm. The bamboo silk decorative layer 12 is arranged on the upper surface of the solid wood strip composite board layer 11 , and the straw woven paper layer 13 is arranged between the solid wood strip composite board layer 11 and the bamboo silk decorative layer 12 .

Embodiment 2

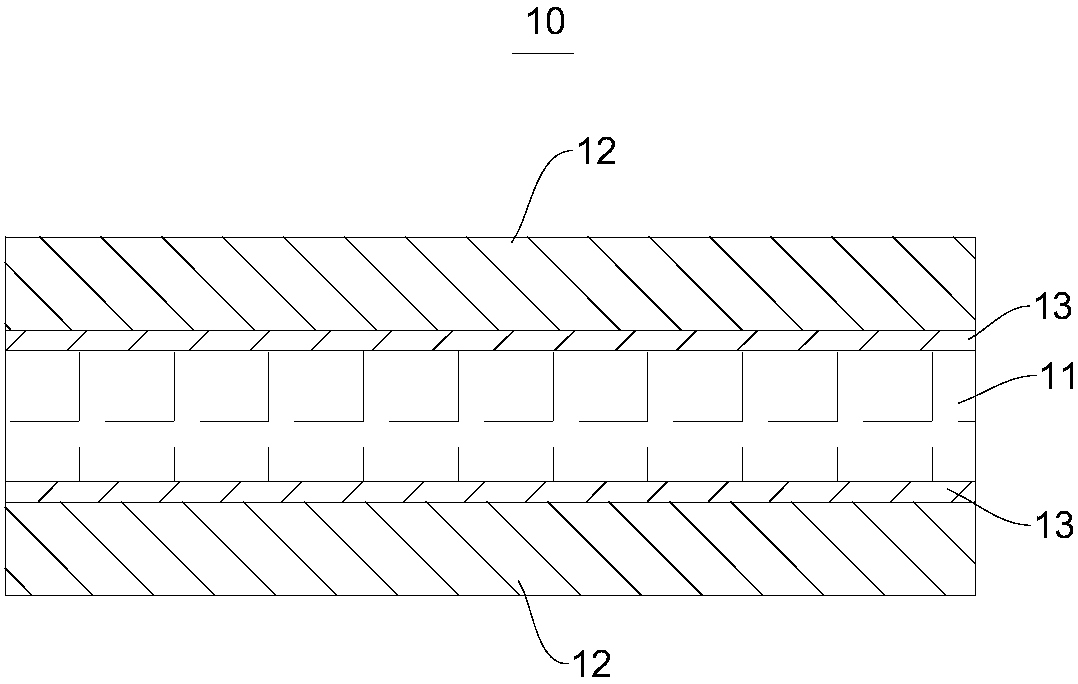

[0056] The humidity-adjustable bamboo fiber decorative panel 10 provided in this embodiment comprises a layer of solid wood strip composite board layer 11 , a layer of bamboo fiber decorative layer 12 and a layer of straw woven paper layer 13 with a thickness of 0.8 mm. The bamboo silk decorative layer 12 is arranged on the lower surface of the solid wood strip composite board layer 11 , and the straw woven paper layer 13 is arranged between the solid wood strip composite board layer 11 and the bamboo silk decorative layer 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com