PP/HDPE/POE composite thermal-conduction polymer material, preparation method and applications thereof

A polymer material, weight percentage technology, applied in the field of PP/HDPE/POE composite thermally conductive polymer materials and its preparation, can solve the problems of low impact resistance, limited application range, poor thermal conductivity, etc., and achieve excellent thermal conductivity, Excellent mechanical properties, simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

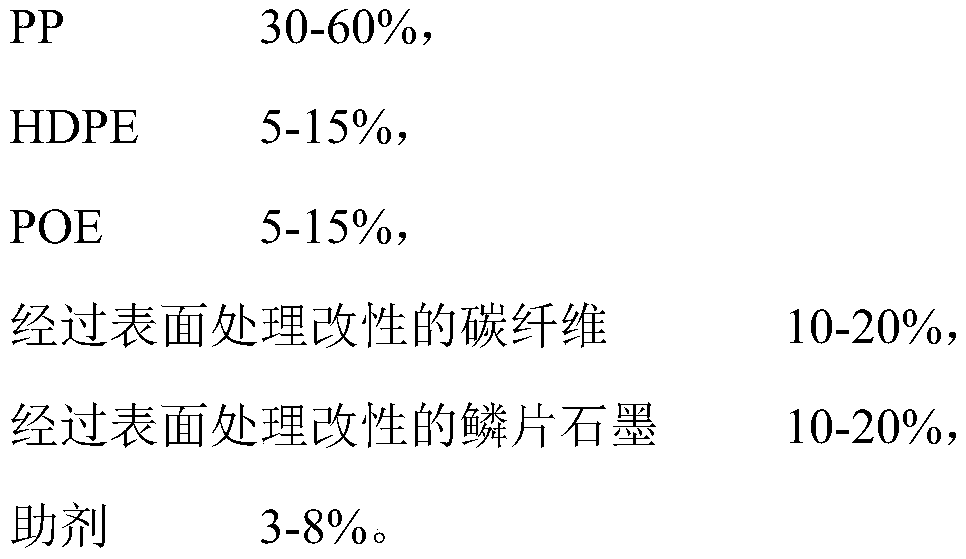

preparation example Construction

[0052] The carbon fiber modified by surface treatment is prepared by the following method: first mix KH-550 and absolute ethanol for 5 minutes to obtain a mixed solution; dry the carbon fiber at 120°C for 3 hours, and then spray the mixed solution on the surface of the carbon fiber, At the same time, the mechanical mixing is carried out continuously, so that the mixed solution is uniformly dispersed in the carbon fibers; the mixed carbon fibers are dried at a temperature of 120° C. to obtain surface-treated modified carbon fibers.

[0053] Wherein, the weight of KH-550 is 2% of the weight of the carbon fiber, and the weight of absolute ethanol is 20% of the weight of the carbon fiber.

[0054] The lengths of carbon fibers modified by surface treatment were 150, 100 and 50 μm, respectively.

[0055] The flake graphite modified by surface treatment is prepared by the following method: first mix KH-570 and absolute ethanol for 5 minutes to obtain a mixed solution; dry the flake g...

Embodiment 1

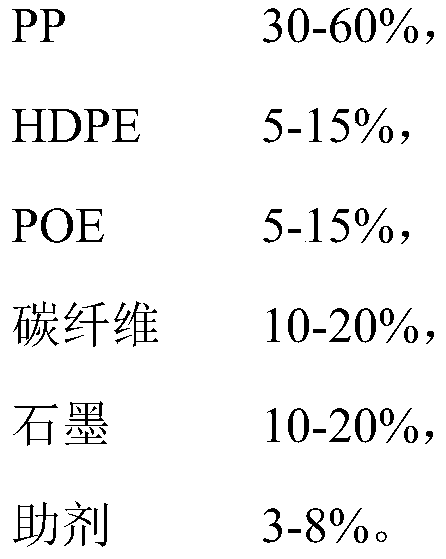

[0059] A PP / HDPE / POE composite thermally conductive polymer material, comprising the following components in weight percentage:

[0060]

[0061] Wherein, the length of the carbon fiber modified by the surface treatment is 100 μm, and the particle size of the flake graphite modified by the surface treatment is 30 μm.

[0062] The preparation method of the PP / HDPE / POE composite thermally conductive polymer material comprises the following steps:

[0063] 1) First dry PP at 80°C for 2 hours, then simply mix the dried PP, surface-treated modified carbon fiber, surface-treated modified flake graphite, antioxidant and liquid paraffin for 5 minutes, and then carry out the same direction Asymmetric extrusion and mixing, extrusion granulation to obtain PP mixed pellets;

[0064] 2) Dry the PP mixed pellets and HDPE obtained in step 1) at 80°C for 3 hours, then simply mix the dried PP mixed pellets, dried HDPE and POE for 5 minutes, and then carry out co-directional asymmetric extr...

Embodiment 2

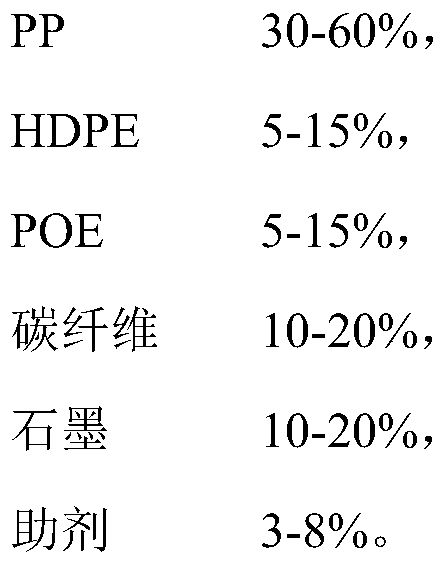

[0069] A PP / HDPE / POE composite thermally conductive polymer material, comprising the following components in weight percentage:

[0070]

[0071]Wherein, the length of the carbon fiber modified by the surface treatment is 100 μm, and the particle size of the flake graphite modified by the surface treatment is 30 μm.

[0072] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com