Method for preparing surface hydroxylated WO3 film photoelectrode material through plasma treatment

A plasma and hydroxylation technology, applied in the field of materials, can solve the problems of increasing the danger of the experimental process, being unfavorable to mass production, increasing the preparation cost, etc., and achieving a wide range of applications, excellent photoelectric catalytic water splitting performance, and increased electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

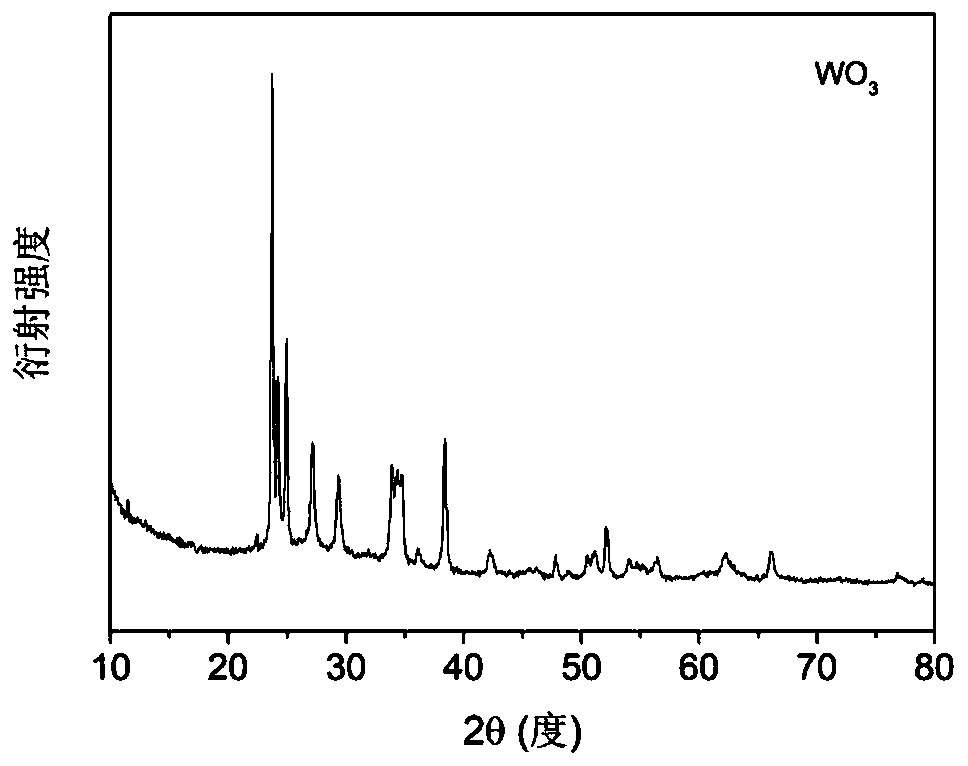

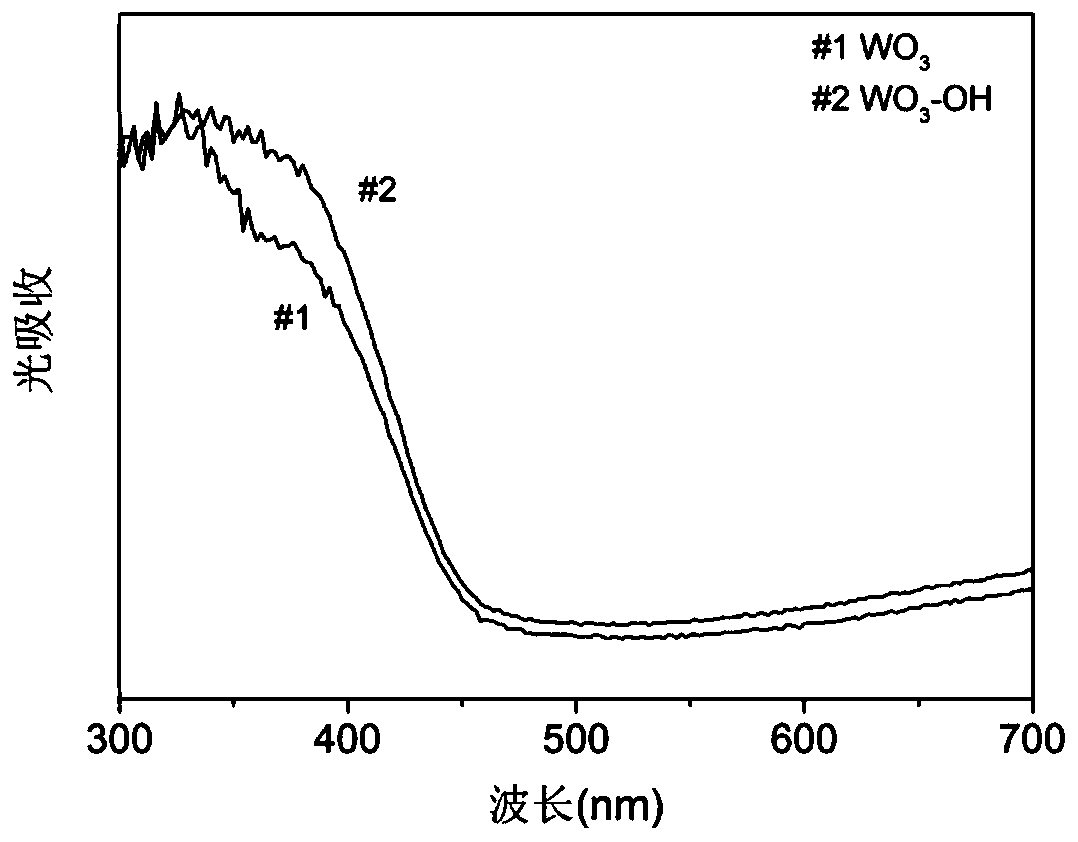

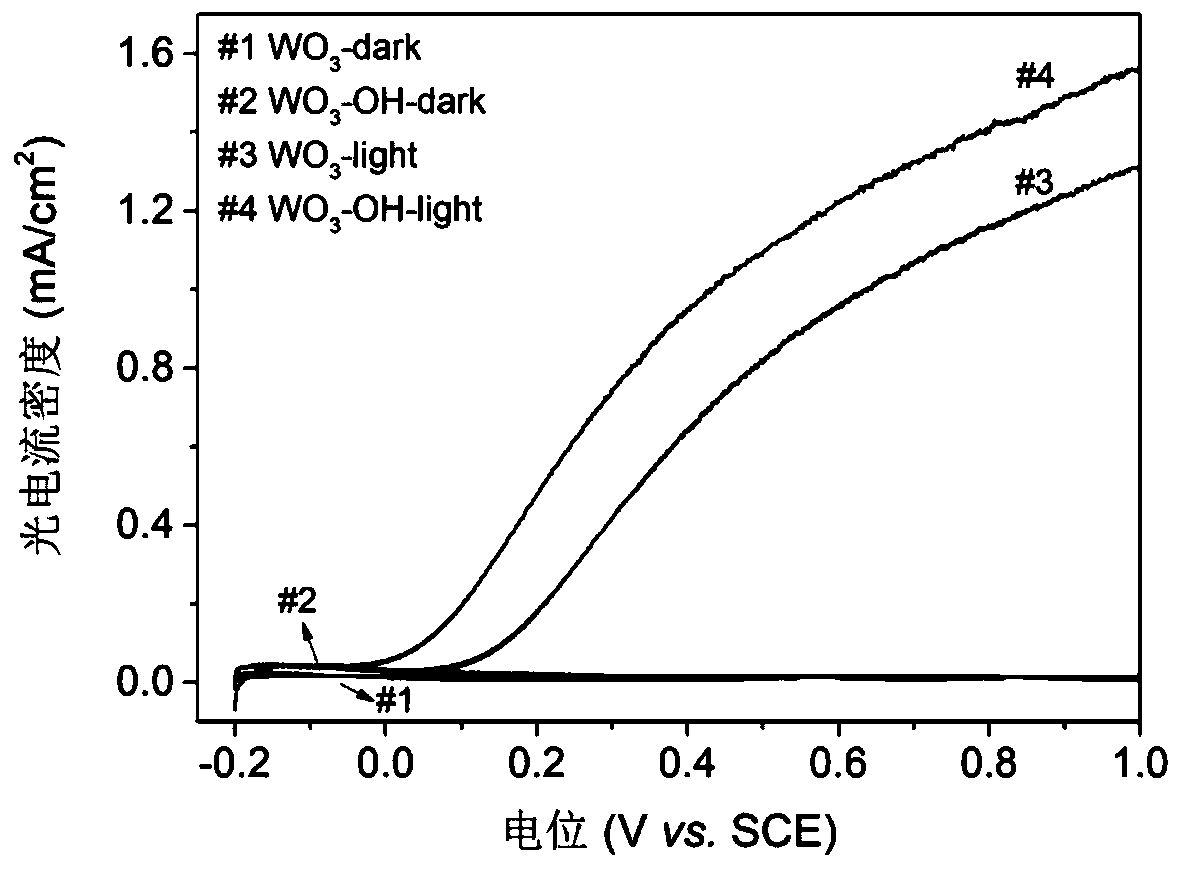

[0022] Preparation of Surface Hydroxylated WO by Plasma Treatment 3 The method for thin film photoelectrode material, concrete steps are as follows: take 1.25g of H 2 WO 4 and 0.5g polyvinyl alcohol (PVA) dissolved in 17ml of H 2 o 2 (30wt%), pipette 200uL above-mentioned solution and spin-coat on FTO, spin coater parameter is set to low-speed 500 rev / s, time 10 seconds, high-speed 1500 revs / sec, time 30 seconds; After the FTO thin film is dried at room temperature, Calcined at 500°C in air for 2h, the heating rate was 180°C / h, to obtain WO 3 / FTO seed crystal; 1.25gH 2 WO 4 Dissolve in 30mL H 2 O, add 17 mL of 30 wt% H 2 o 2 , heated at 95°C for 2h to obtain a clear solution, and dilute it to a 100ml volumetric flask to obtain 0.05mol / L of H 2 WO 4 solution; add 3mL H in 10mL acetonitrile 2 WO 4 (0.05mol / L) solution, 0.2g oxalic acid, 0.5mL hydrochloric acid solution with a concentration of 6mol / l and 2.5ml deionized water, stir for 15min to fully stir the solutio...

Embodiment 2

[0024] Preparation of Surface Hydroxylated WO by Plasma Treatment 3 The method for thin film photoelectrode material, concrete steps are as follows: take by weighing 1.5g of H 2 WO 4 and 0.6g of polyvinyl alcohol (PVA) dissolved in 20ml of H 2 o 2 (30wt%), pipette 200uL above-mentioned solution and spin-coat on FTO, spin coater parameter is set to low speed 600 revs / sec, time 15 seconds, high speed 1800 revs / sec, time 20 seconds; After the FTO thin film is dried at room temperature, Calcined at 500°C in air for 2h, the heating rate was 180°C / h, to obtain WO 3 / FTO seed crystal; 1.5gH 2 WO 4 Dissolve in 30mL H 2 O, add 20 mL of 30 wt% H 2 o 2 , heated at 95°C for 2 hours to obtain a clear solution, and dilute it to a 100ml volumetric flask to obtain 0.06mol / L of H 2 WO 4 solution; add 3mL H in 10mL acetonitrile 2 WO 4 (0.06mol / L) solution, 0.2g oxalic acid, 0.5mL hydrochloric acid solution with a concentration of 6mol / l and 2.5ml deionized water, stir for 15min to f...

Embodiment 3

[0026] Preparation of Surface Hydroxylated WO by Plasma Treatment 3 The method for thin film photoelectrode material, concrete steps are as follows: take 2g of H 2 WO 4 and 0.8g polyvinyl alcohol (PVA) dissolved in 25ml of H 2 o 2 (30wt%), pipette 200uL above-mentioned solution and spin-coat on FTO, spin coater parameter is set to low speed 800 rev / s, time 10 seconds, high speed 2000 revs / sec, time 20 seconds; After the FTO film room temperature drying, Calcined at 500°C in air for 2h, the heating rate was 180°C / h, to obtain WO 3 / FTO seed; 1.25g H 2 WO 4 Dissolve in 30mL H 2 O, add 17 mL of 30 wt% H 2 o 2 , heated at 95°C for 2h to obtain a clear solution, and dilute it to a 100ml volumetric flask to obtain 0.05mol / L of H 2 WO 4 solution; add 3mL H in 10mL acetonitrile 2 WO 4 (0.05mol / L) solution, 0.2g oxalic acid, 0.5mL hydrochloric acid solution with a concentration of 6mol / l and 2.5ml deionized water, stir for 15min to fully stir the solution evenly, with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com