A motor cover with bearing arrangement

A bearing device and motor cover technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of coaxiality, poor precision, poor consistency of oil bearing performance, and difficulty in ensuring precision, etc., to improve the coaxiality , Strong product consistency and fewer assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

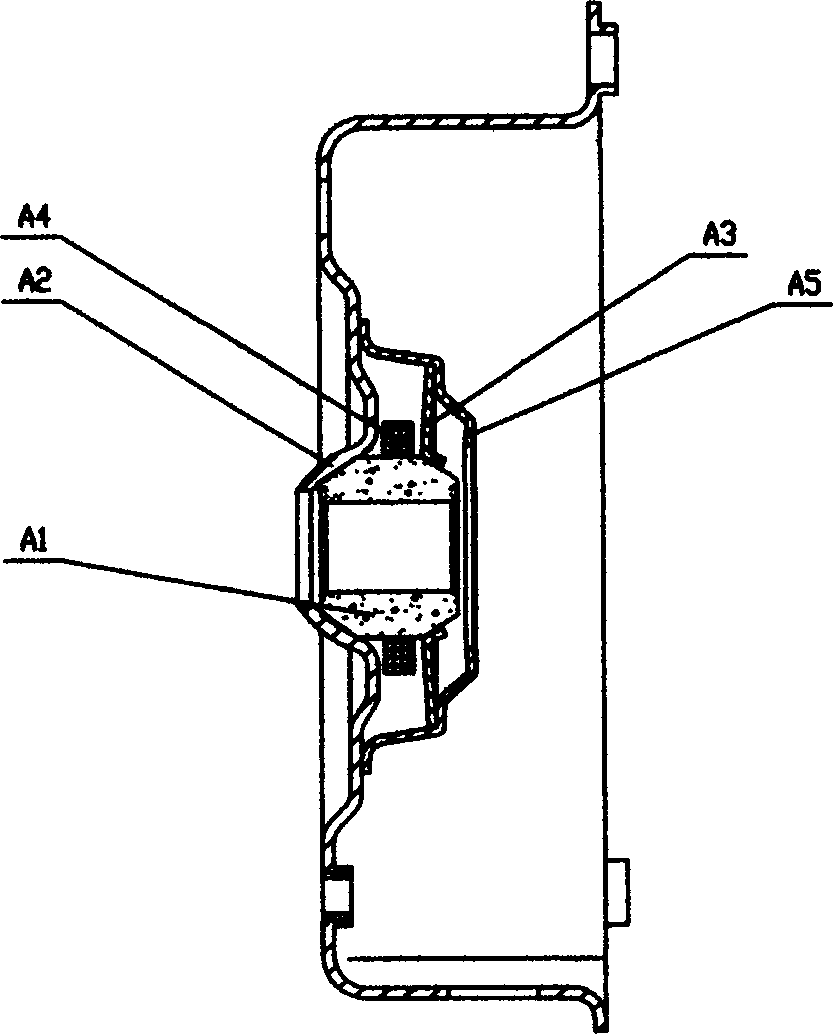

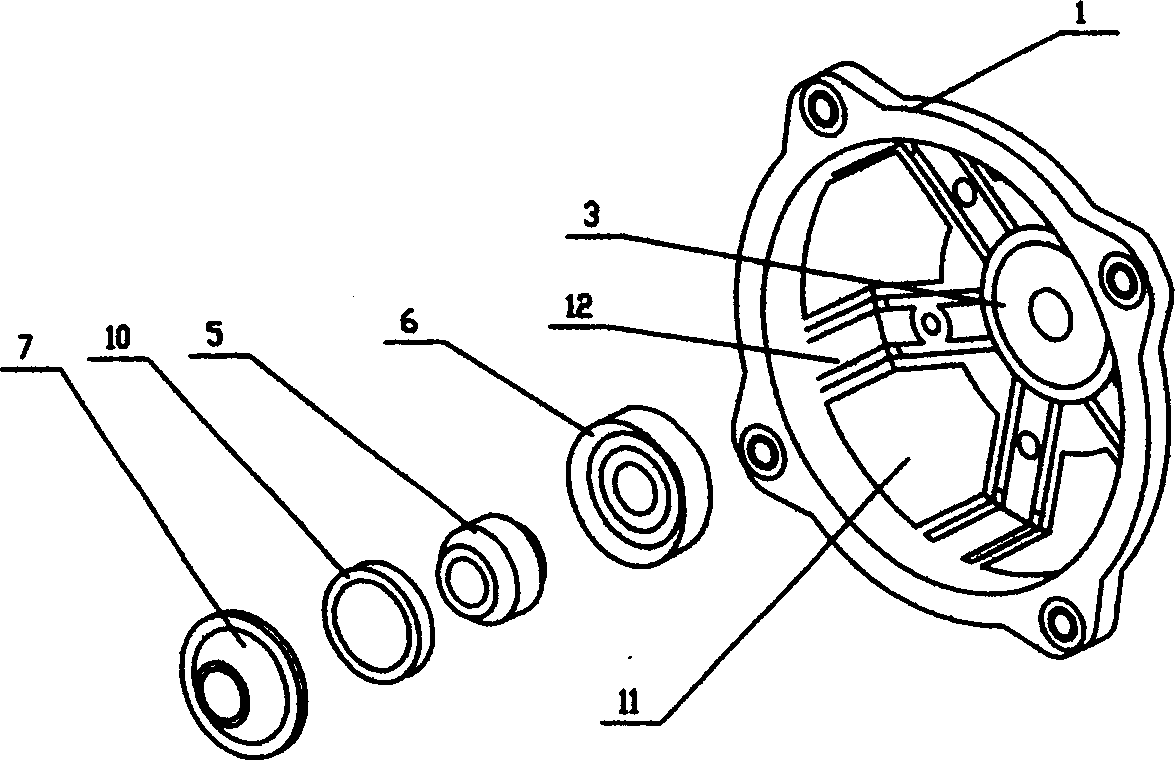

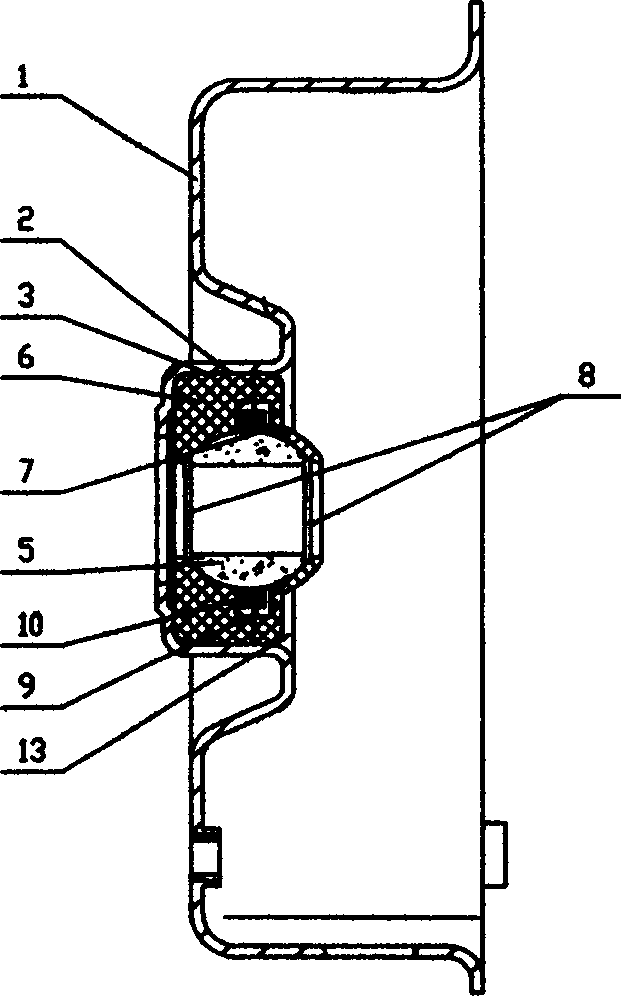

[0023] Such as figure 2 , image 3 As shown, this embodiment consists of a housing 1 and a plastic-sealed bearing device 2 . The middle part of the housing 1 is provided with a bearing device mounting seat 3 . The casing 1 is provided with a gap 11 , and a support bar 12 is formed between the gap 11 and the gap 11 , and the support bar 12 supports and fixes the bearing device mounting seat 3 . Only using the support bar 12 to support the bearing device installation seat 3 is beneficial to reduce the material cost of the housing. The bearing device mounting seat 3 is integrally formed with the housing 1 . The housing 1 is made of flame-retardant plastic material ABS or PC or PP. The plastic-sealed bearing device 2 is located in the bearing device mounting seat 3 . The fixed end cover 13 is embedded in the bearing device mounting seat 3 to fix the plastic-sealed bearing device 2 . The plastic-encapsulated bearing device 2 is made up of a plastic base and an oil-impregnate...

specific Embodiment 2

[0024] Such as Figure 4 As shown, the characteristics of this specific embodiment are: the bearing seat 6 of the plastic-sealed bearing device 2 and the bearing device mounting seat 3 are connected as a whole, and they are integrally formed and made together when the housing 1 is injected. The bearing seat 6 is integrally formed with the housing, so that the bearing seat 6 is coaxial with the bearing device mounting seat 3, thereby facilitating the rotating performance of the bearing. The parts of the oil cup 7 are matched with the bearing seat at the injection molded housing, and then fused together by ultrasonic welding process to form the bearing chamber cavity.

[0025] Except for the oil-impregnated bearing, all the constituent materials of the present invention can be injection molded by plastics. Favorable to reduce costs. Ideal replacement for existing motor covers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com