Symmetrical-stripe-and-check cutting method and system

A grid-aligning and strip-aligning technology, applied in the field of cutting bed, can solve the problems of low cutting efficiency and poor precision, and achieve the effect of reducing labor costs, reducing production costs, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

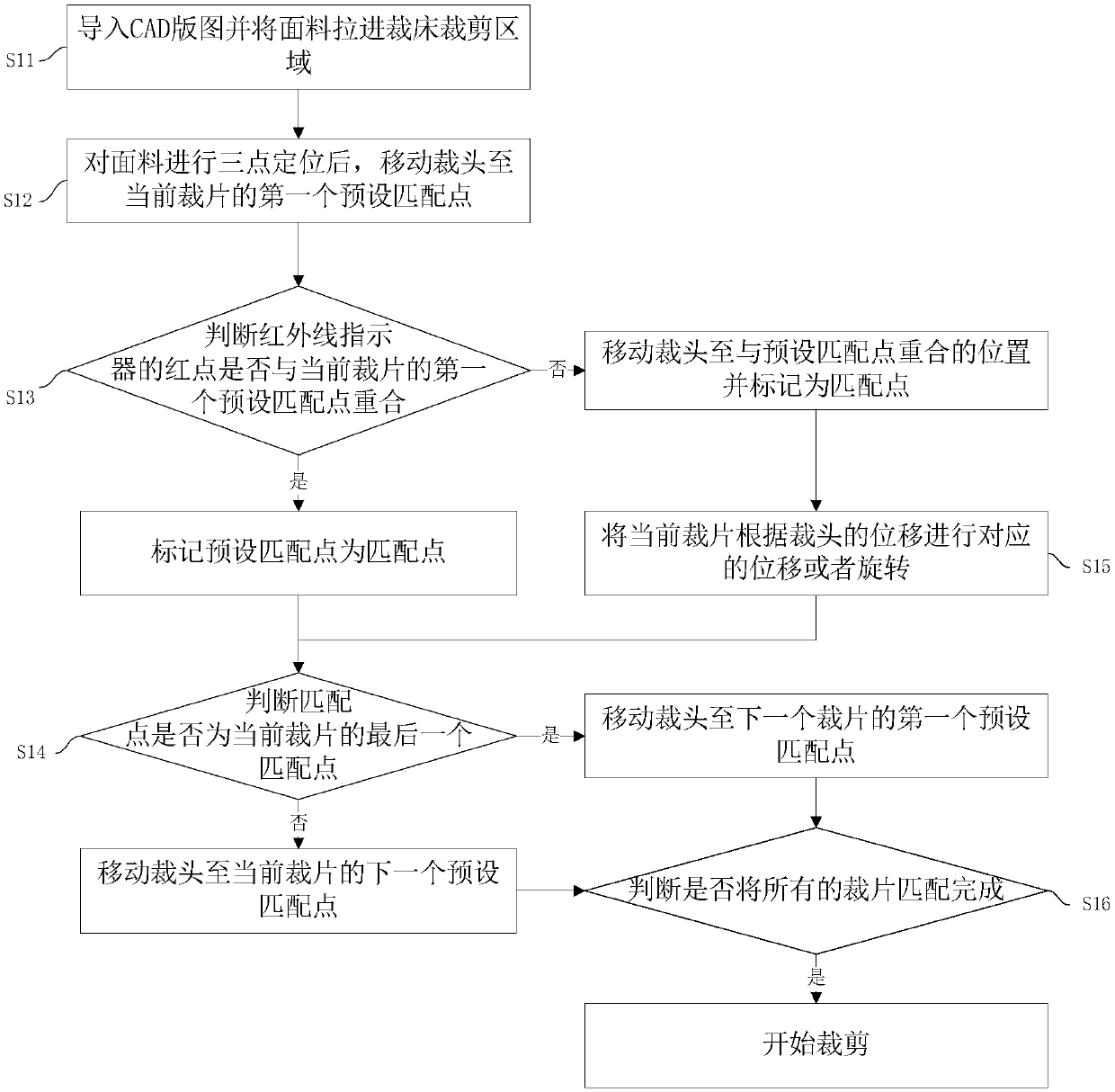

[0041] This embodiment provides a method for cutting the bars to the grid, such as figure 1 shown, including steps:

[0042] S11: Import the CAD layout and pull the fabric into the cutting area of the cutting bed;

[0043] S12: After three-point positioning of the fabric, move the cutting head to the first preset matching point of the current piece;

[0044] S13: Determine whether the red point of the infrared indicator of the cutting head coincides with the first preset matching point of the current piece, if so, mark the preset matching point as the matching point; otherwise, move the cutting head to coincide with the preset matching point and marked as matching points;

[0045] S14: After marking the preset matching point as the matching point, judge whether the matching point is the last matching point of the current piece, if so, move the cutting head to the first preset matching point of the next piece; otherwise, move the cutting head To the next preset matching po...

Embodiment 2

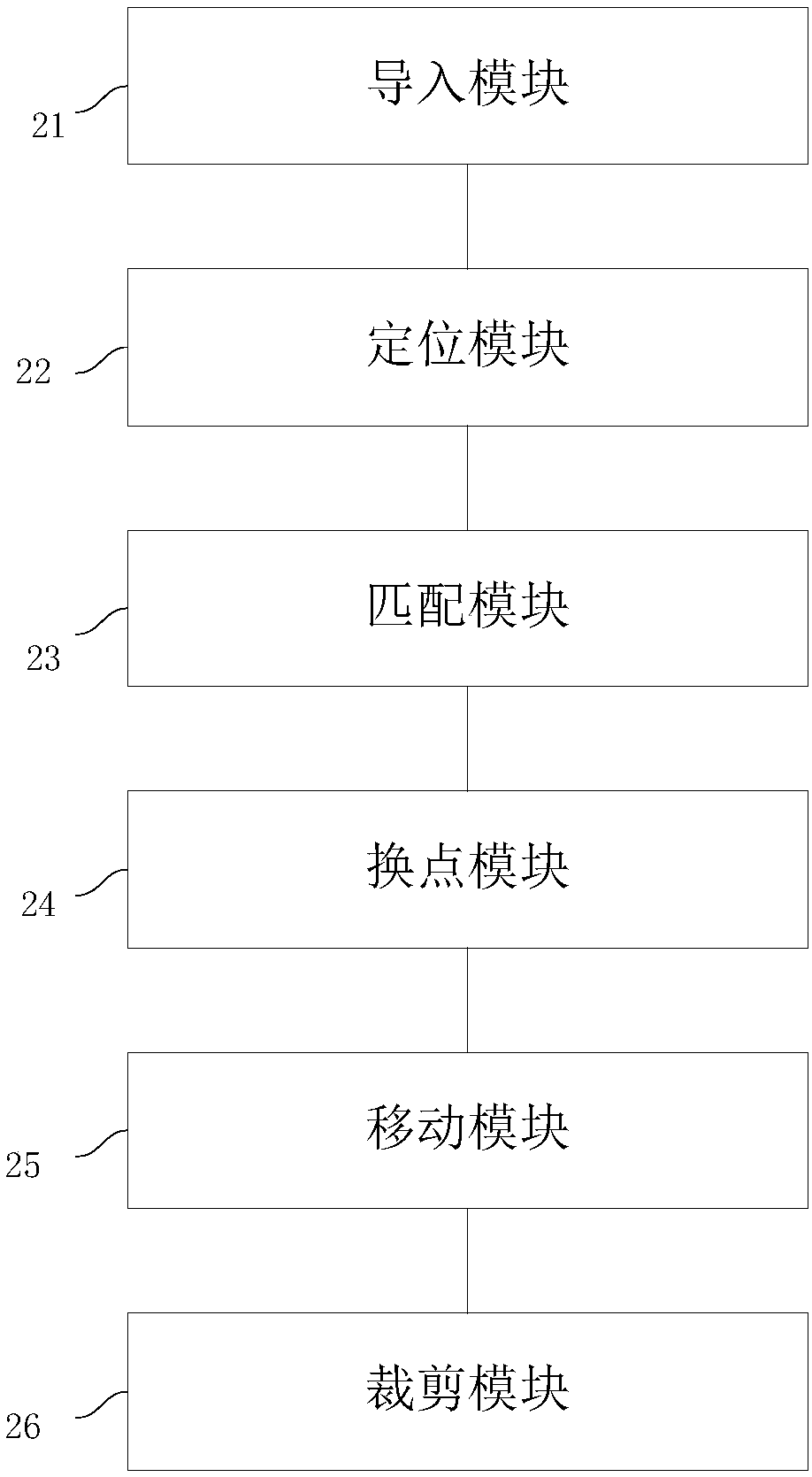

[0075] The present embodiment provides a kind of bar to grid cutting system, such as figure 2 shown, including:

[0076] The import module 21 is used to import the CAD layout and pull the fabric into the cutting bed cutting area;

[0077] The positioning module 22 is used to move the cutting head to the first preset matching point of the current piece after performing three-point positioning on the fabric;

[0078] Matching module 23 is used to judge whether the red point of the infrared indicator of the cutting head coincides with the first preset matching point of the current cut piece, if so, mark the preset matching point as the matching point; otherwise, move the cutting head to match the preset matching point. Set the position where the matching points coincide and mark it as a matching point;

[0079] Change the point module 24, after being used to mark the preset matching point as the matching point, judge whether the matching point is the last matching point of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com