Clostridium butyricum liquid fermentation preparation method and liquid culture medium

A fermentation medium, the technology of Clostridium butyricum, applied in the field of liquid fermentation culture and fermentation technology of anaerobic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

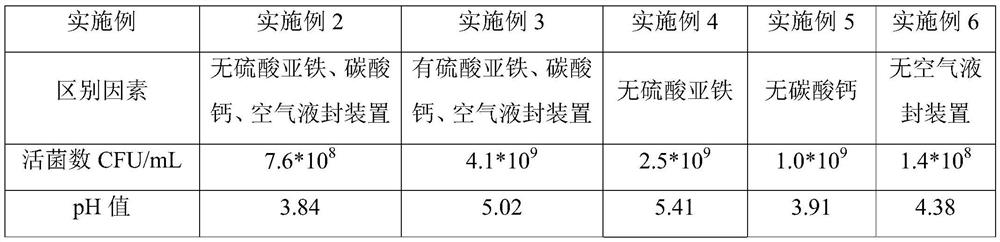

Examples

Embodiment 1

[0027] Clostridium butyricum was taken out from the -80°C refrigerator and inoculated into 3L seed medium, and cultured at 37°C for 18 hours. Afterwards, insert 2% of the inoculum into the 150L fermentation medium of the 200L fermenter for anaerobic culture at 37°C, turn on the motor for stirring, the speed is 80r / min, and open the valve of the air liquid seal device, and the culture time is 20h, and the activity of Clostridium butyricum is detected. The number of bacteria and the pH value of the fermentation broth.

[0028] Wherein, the seed medium is: glucose monohydrate 5g / L, soluble starch 10g / L, yeast extract 10g / L, dipotassium hydrogen phosphate 2g / L, calcium carbonate 8g / L, tomato powder 0.5g / L, pH7.0. The fermentation medium is: glucose monohydrate 5g / L, soluble starch 10g / L, yeast extract 10g / L, dipotassium hydrogen phosphate 2g / L, calcium carbonate 8g / L, tomato powder 0.5g / L, pH7. 0. Set different concentration gradients for ferrous sulfate: 0g / L, 2g / L, 4g / L, 6g / L...

Embodiment 2

[0034] Clostridium butyricum was taken out from the -80°C refrigerator and inoculated into 3L seed medium, and cultured at 37°C for 18 hours. Afterwards, insert 2% inoculum amount into 150L fermentation medium in a 200L fermenter for anaerobic culture at 37°C, turn on the motor for stirring, the rotation speed is 80r / min, and the culture time is 20h. The ingredients of the seed medium and fermentation medium are: glucose monohydrate 5g / L, soluble starch 10g / L, yeast extract 10g / L, dipotassium hydrogen phosphate 2g / L, tomato powder 0.5g / L, pH7.0 . Ferrous sulfate and calcium carbonate are not added in the culture medium of this embodiment, and the air liquid seal device is not used in the fermentation process.

Embodiment 3

[0036]Clostridium butyricum was taken out from the -80°C refrigerator and inoculated into 3L seed medium, and cultured at 37°C for 18 hours. Afterwards, insert 2% of the inoculum into 150L fermentation medium in a 200L fermenter for anaerobic culture at 37°C, turn on the motor for stirring at a speed of 80r / min, and open the valve of the air liquid seal device for 20h of culture time. The composition of the seed medium and fermentation medium is: glucose monohydrate 5g / L, soluble starch 10g / L, yeast extract 10g / L, dipotassium hydrogen phosphate 2g / L, ferrous sulfate 8g / L, calcium carbonate 8g / L, tomato powder 0.5g / L, pH7.0. This embodiment is the solution of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com