Method for preparing lithium ion battery anode material LiNi0.5Mn1.5O4

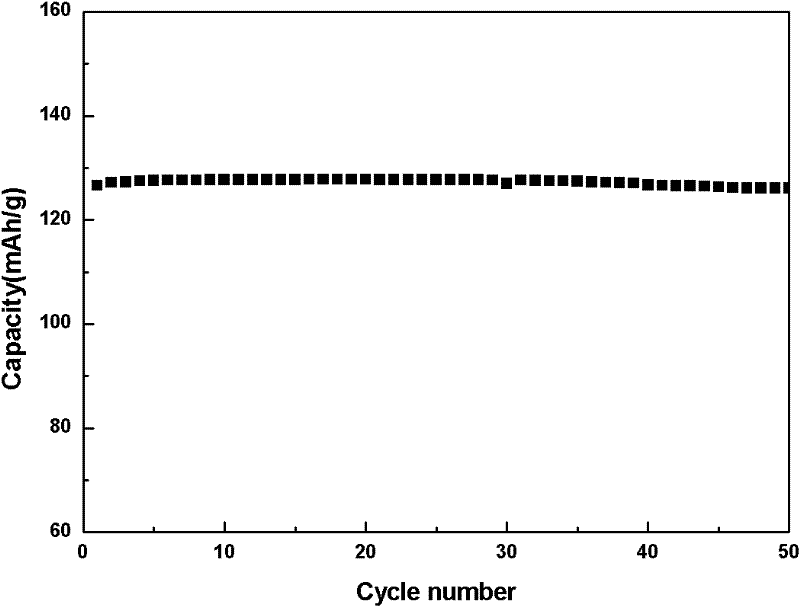

A technology for lithium-ion batteries and positive electrode materials, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of small number of samples, inability to achieve continuity, poor performance, etc., and achieve reduced production process steps and stable cycle Excellent, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 The preparation method is characterized in that: comprises the following steps:

[0021] (1) Liquid phase ball milling: weigh the lithium compound, the nickel-containing compound and the manganese-containing compound at a ratio of 1:1-1.5:2-5 in a mass ratio of the lithium-containing compound, the nickel-containing compound, and the manganese-containing compound, and place them in a solvent liquid-phase ball milling; the total amount of the three compounds and the content of the solvent are 0.1-0.3g / ml;

[0022] (2) Spray drying: Put the ball mill product into a high-speed spray dryer for spray drying. The inlet and outlet temperatures of the spray dryer are 160-300°C and 80-120°C respectively, and the rotation speed of the atomizing disc in the spray dryer is 20,000 -40000r / min;

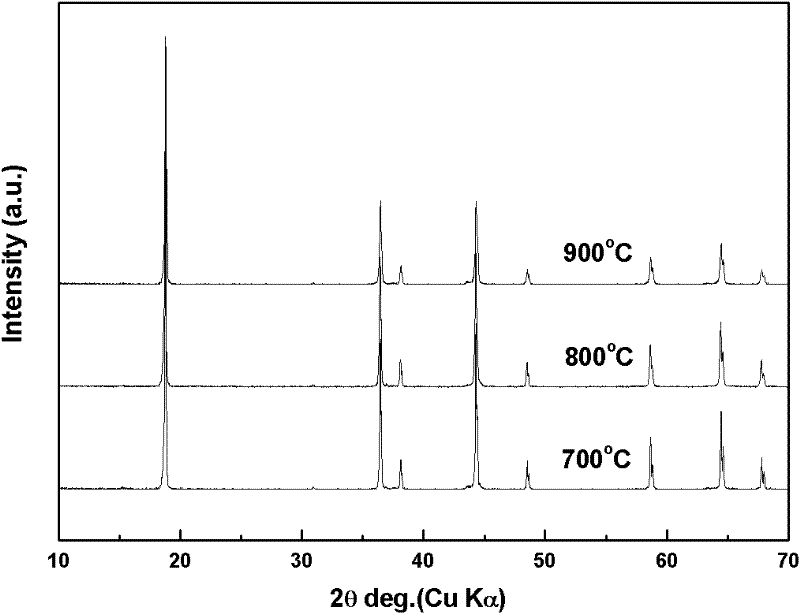

[0023] (3) Sintering: The spray-dried product is kept at a constant temperature of 500-1200°C for 1-16 hours in an air o...

Embodiment 1

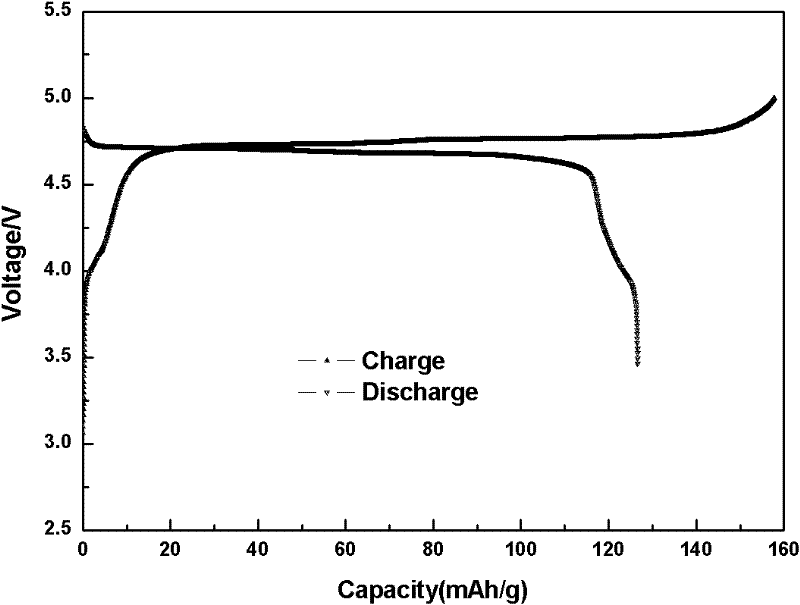

[0029] 194.33g of Li 2 CO 3 , 199.75g of NiO and 605.30g of Mn 3 o 4 Add to 5000mlC 2 h 5 In OH, put it into a high-speed spray dryer for spray drying after ball milling by a stirring ball mill for 2 hours. The inlet temperature of the spray dryer is set to 180°C, the outlet temperature is set to 80°C, and the rotation speed of the atomizing disc in the spray dryer is 25000r / Min, spray the obtained product into the muffle furnace, in the air atmosphere, heat up to 800°C at a rate of 10°C / min, keep the temperature for 10h, and naturally cool to room temperature, that is, LiNi, the positive electrode material for lithium-ion batteries. 0.5 mn 1.5 o 4 .

Embodiment 2

[0031] The sintering temperature is 700° C., and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com